|

Remove and refit timing case (Z 10 XE, Z 10 XEP,

with air conditioning, LHD)

Note: KM-6394 must be used as of model year 04 instead of

KM-6169-1 .

Remove Remove

| 2. |

Disconnect battery

Note: On vehicles as of

model year 04 with ESP - every time the battery is disconnected,

the steering angle sensor loses its basic setting. It must be

recalibrated.

|

| 3. |

Drain coolant

Note: With model

variant "ECO" - remove lower engine compartment cover

| • |

Place collecting basin underneath.

|

| • |

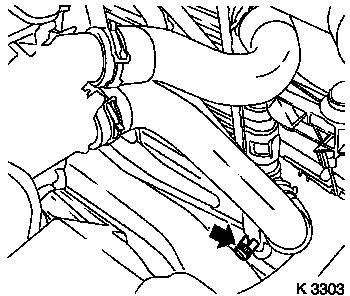

Open drain bolt (arrow)

|

|

|

|

| 4. |

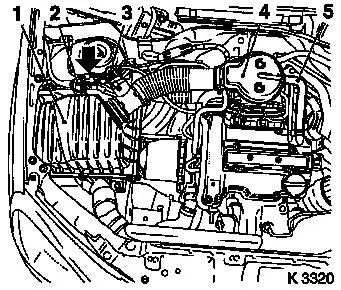

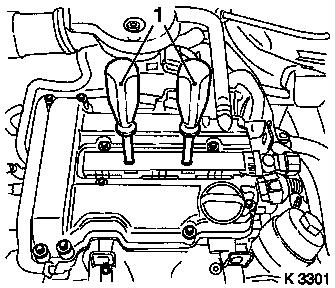

Remove air cleaner housing (1)

| • |

Disconnect 2 wiring harness plugs

| – |

Hot film mass air flow sensor (3), tank vent valve (2)

|

|

| • |

Remove suction pipe (4)

| – |

Detach engine vent hose (5)

|

|

| • |

On Z 10 XEP: Remove air intake hose

|

|

|

|

| 5. |

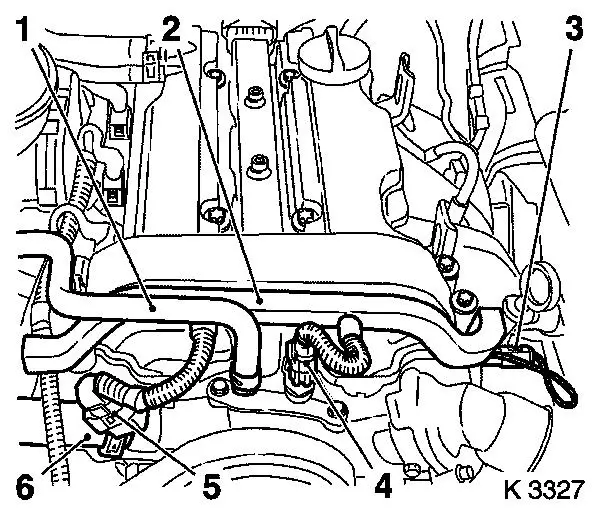

Detach throttle body preheater hose (1)

|

| 6. |

Detach heater supply hose (6) from coolant pump

|

| 7. |

Remove engine management wiring harness

| • |

Disconnect 3 wiring harness plugs

| – |

oil pressure switch (3), coolant temperature sensor (4) and

camshaft sensor (5)

|

|

| • |

Unclip wiring trough (2)

|

| • |

Set wiring harness to one side

|

|

|

|

| 8. |

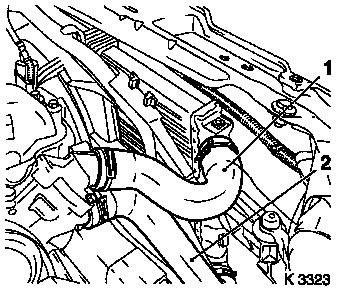

Remove upper radiator hose (1)

|

| 9. |

Detach lower radiator hose (2) from coolant pump

|

|

|

| 10. |

Remove ignition module

| • |

Remove ignition module cover

|

| • |

Disconnect wiring harness plug

|

| • |

Extract using KM-6009 (1)

Note: Do not tilt

|

|

| 11. |

Remove cylinder head cover

| • |

Detach engine vent hose

|

|

| 12. |

Detach front right wheel

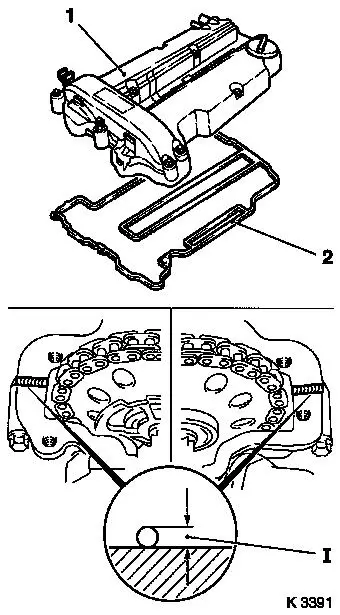

|

| 14. |

Remove right front wheel

|

|

|

| 16. |

Remove ribbed V-belt cover

Note: With model

variant "ECO" - remove lower engine compartment cover

|

|

|

| 17. |

Close coolant drain bolt

|

| 18. |

Drain engine oil

| • |

Place another collecting basin underneath

|

|

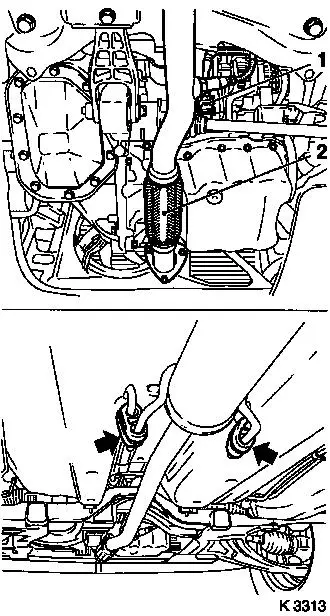

Important: Angular dislocations

of the flexpipe as small as 5 to 10 degrees offset from the

intended installation position can cause damage and subsequent

complete failure of the flexpipe.

|

| 19. |

Loosen exhaust system

Note: When removing the

centre muffler, a catalytic converter, an exhaust manifold or an

exhaust manifold with catalytic converter, the exhaust system piece

remaining in the vehicle must be secured to prevent it sagging

uncontrollably. The exhaust system piece with the flex pipe inside

it can be fastened to the vehicle underbody with suitable materials

such as wire.

| • |

Detach oxygen sensor (catalytic converter control) wiring

harness plug (1)

|

| • |

Detach 2x damper rings (arrows)

|

| • |

Unbolt front exhaust pipe (2)

|

| • |

Suspend front exhaust pipe from left front axle body

|

|

|

|

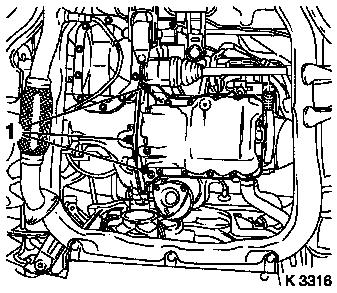

| 20. |

Tighten engine oil drain bolt 10

Nm

|

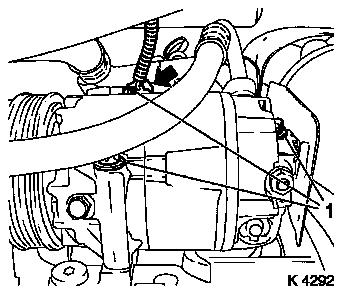

| 21. |

Detach alternator wiring harness (1)

|

|

|

| 22. |

Remove ribbed V-belt

| • |

Tension ribbed V-belt tensioner in direction of arrow with

KM-6131

|

|

| 23. |

Remove ribbed V-belt tensioner

Note: Ensure that the

ribbed V-belt tensioner is positioned correctly (arrow pointing

upwards). If this cannot be guaranteed the ribbed V-belt tensioner

must be bled. At least 5 strokes must be performed

(tensile/pressure load), whereby the load speed should be constant

and the application of load even. Damage to the tensioning element

must be avoided!

| • |

Tension ribbed V-belt tensioner with KM-6131

|

| • |

Release ribbed V-belt tensioner

|

|

|

|

| 24. |

Remove alternator

| • |

Detach 2x screw connections (1)

|

|

|

|

| 25. |

Remove oil pan

| • |

Crankshaft bearing bridge

|

|

|

|

| 26. |

Attach KM-6169-2 to transmission

|

|

|

| 27. |

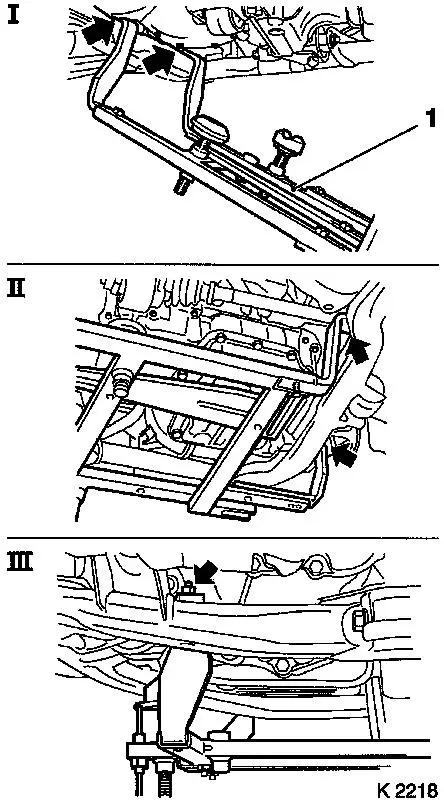

Attach KM-6169 (1)

| • |

Attach KM-6169 to left of front axle

body (arrows, illus. I)

Note: Guide pin must be

seated in bore in front axle body

|

| • |

Attach both right holders on the front axle body (arrows,

Illus. II).

Note: Guide pin must be

seated in bore in front axle body (arrow, Fig. III)

|

|

|

|

|

| 28. |

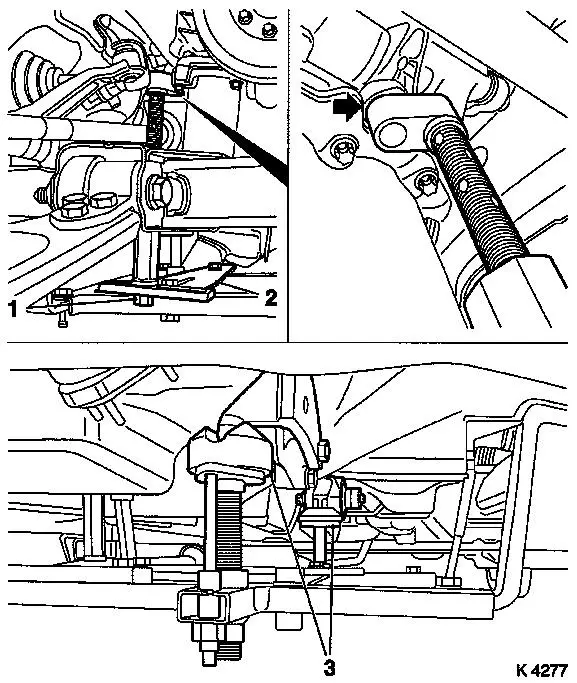

Install support

| • |

An KM-6169

| – |

Adjust bracket (2) for support

|

|

|

| 29. |

Adjust supports

| • |

Transmission side

| – |

Turn spindles until mounts (3) are positioned at guide journals

free of play

|

|

| • |

Engine timing side

| – |

Insert journal of the support in the bore of the cylinder block

without play (arrow)

|

|

|

|

| 30. |

Loosen right engine bracket

|

|

|

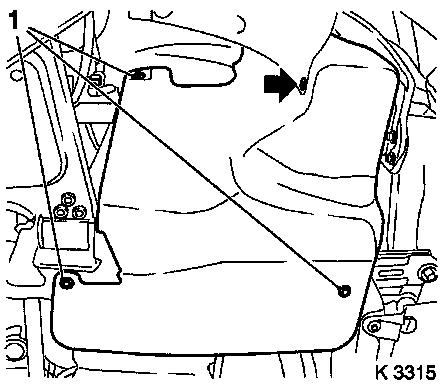

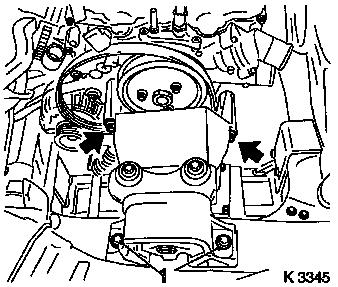

| 32. |

Remove compressor

Note: The air

conditioning system remains closed

| • |

Disconnect wiring harness plug (arrow)

|

|

|

|

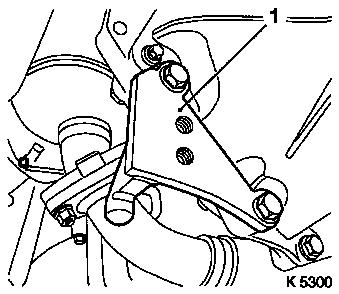

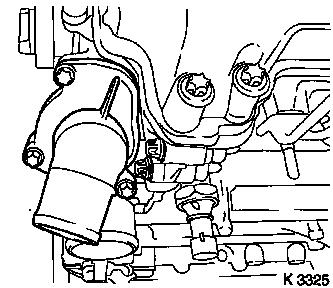

| 34. |

Remove right engine bracket

| • |

Loosen engine damping block

|

| • |

Unscrew 2x bolt (arrows)

|

|

|

|

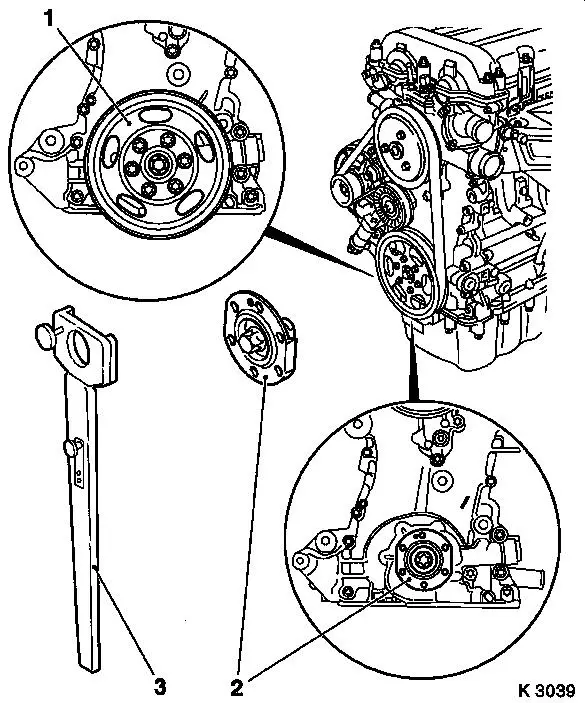

| 35. |

Remove coolant pump ribbed V-belt pulley

|

| 36. |

Detach ribbed V-belt tensioner

|

| 37. |

Detach coolant connection

|

|

|

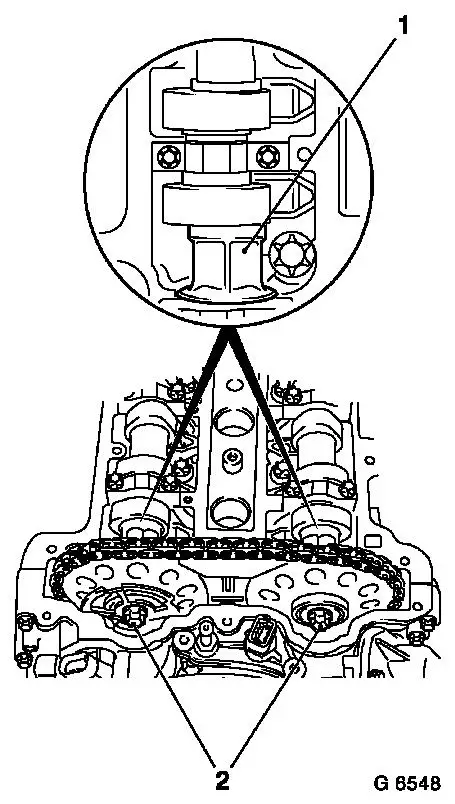

|

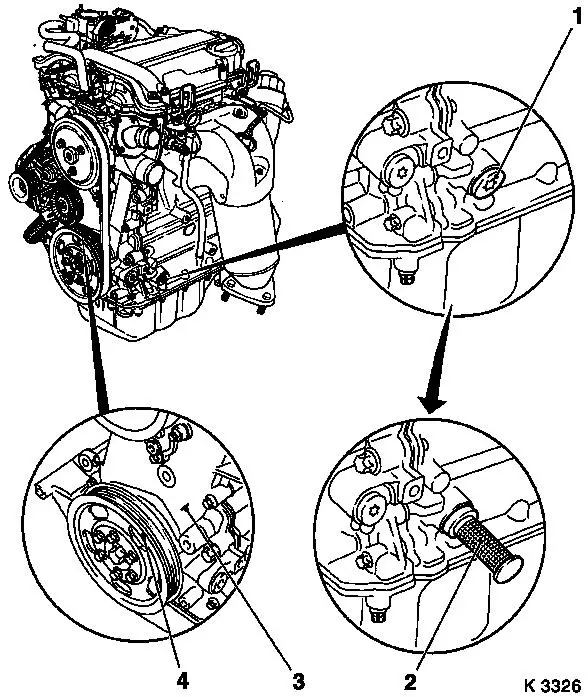

| 38. |

Set no.1 cylinder to TDC

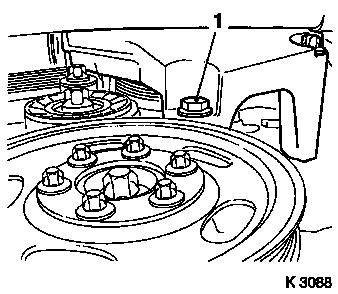

| • |

Remove closure bolt for crankshaft bearing bridge (1)

|

| • |

Insert KM-952 (2)

Note: Crankshaft belt

pulley (4) must line up with lug (3) on timing case

| – |

Turn crankshaft uniformly until KM-952 engages

|

|

|

|

|

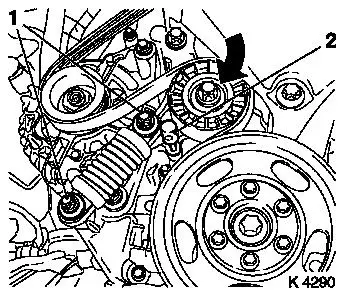

| 39. |

Insert KM-953 (1)

Note: KM-953 must engage in camshaft groove

|

|

|

| 42. |

Detach crankshaft ribbed V-belt pulley (1)

| • |

Counterhold at crankshaft hub bolt

|

|

| 43. |

Loosen crankshaft hub bolt

Note: Second person

required

| • |

Attach KM-956-1 / KM-956-2 (3)

|

| • |

Counterhold KM-956-1 / KM-956-2

|

|

| 44. |

Remove crankshaft hub (2)

Note: Pay attention to

installation position

| • |

Remove with KM-956-1 / KM-956-2

|

|

|

|

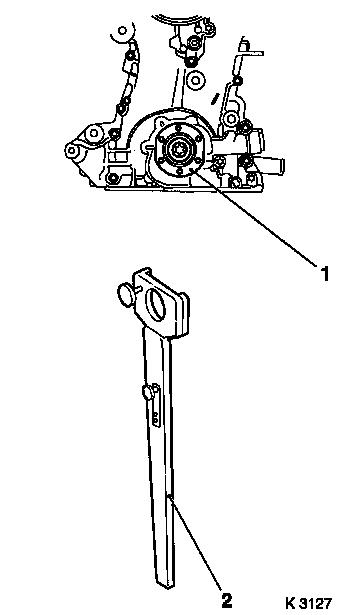

| 45. |

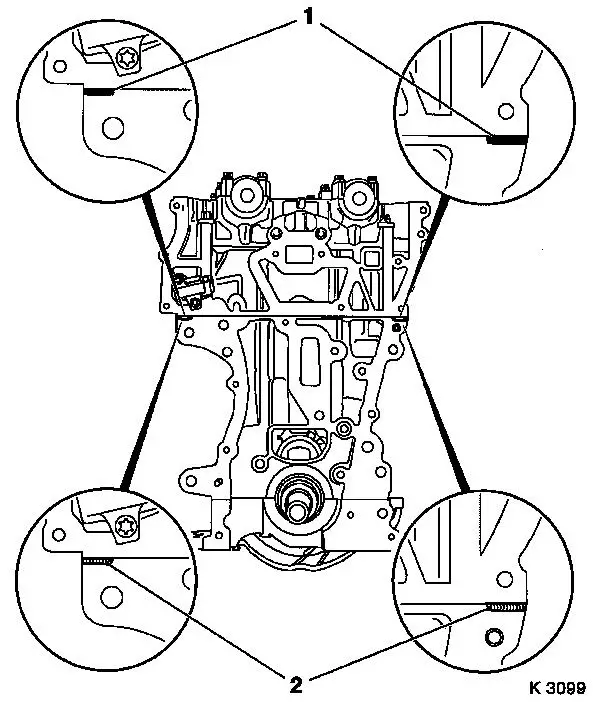

Unscrew timing case at bottom

Note: Note dissimilar

bolt lengths

| • |

Unscrew 2x bolts (3) (M10)

|

| • |

Unscrew 14x bolts (M6) (arrows)

|

|

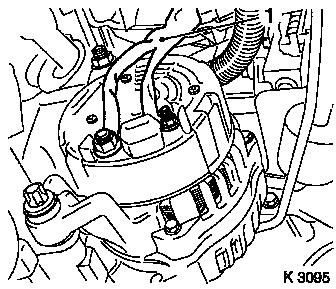

| 47. |

Remove coolant pump

Note: Note guide

bushings during removal

| • |

Place another collecting basin underneath

|

| • |

Unscrew 4 bolts (2)

Note: Note dissimilar

bolt lengths

|

|

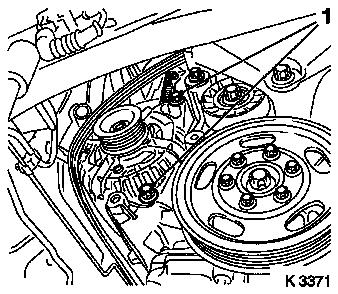

| 48. |

Remove timing case

| • |

Unscrew 4x bolt (1)

Note: Note dissimilar

bolt lengths

|

|

|

|

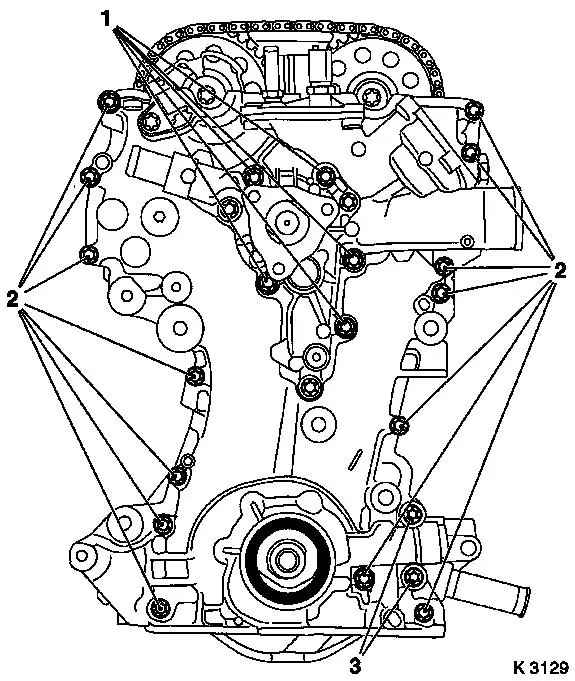

| 49. |

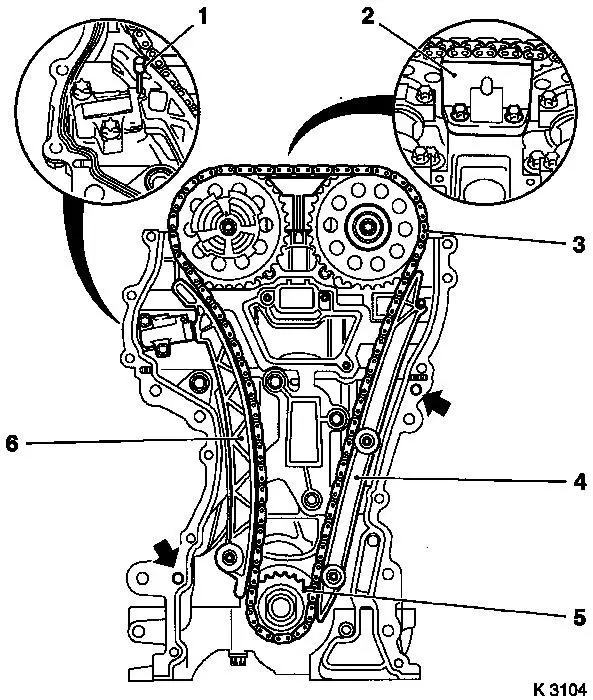

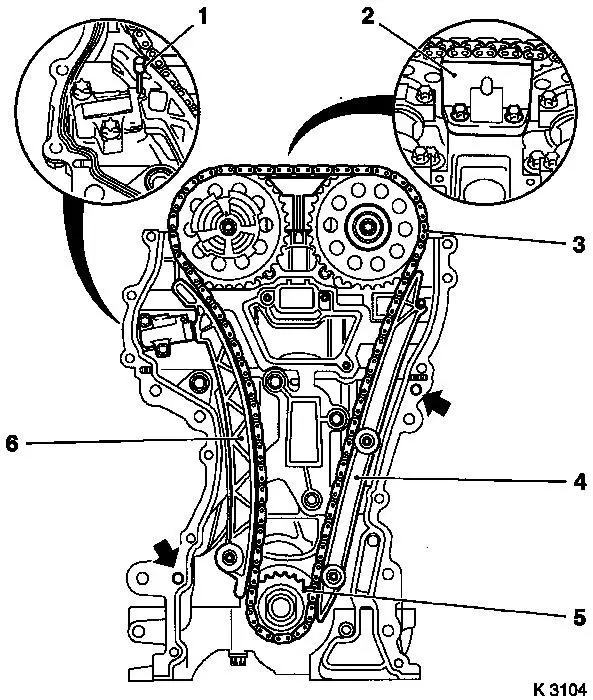

Remove chain drive

| • |

Undo 2x camshaft sprocket bolts

| – |

Counterhold camshafts at hexagonal section

|

|

| • |

Lock chain tensioner (1)

|

| • |

Detach sliding rail (3), guide rail (5), tension rail (7) and

camshaft sprockets

|

| • |

Remove timing chain (4) with drive sprocket (6)

|

| • |

Remove timing case gasket.

|

|

|

| 50. |

Remove front crankshaft seal ring

| • |

Lever out seal ring

Note: Do not damage

sealing surface

|

|

Install

Install

|

| 51. |

Clean sealing surfaces

| • |

Timing case, cylinder block, cylinder head, crankshaft bearing

bridge, oil pan, cylinder head cover, coolant pump, thermostat

housing

|

| • |

If present, remove sealing compound from vicinity of cylinder

head gasket

|

|

| 52. |

Inspect components

Note: If cylinder head

is to be checked and overhauled : Remove all outer attaching parts

from cylinder head

| • |

Chain drive, timing case, cylinder block, cylinder head,

crankshaft bearing bridge, oil pan, cylinder head cover, coolant

pump, thermostat housing

|

|

| 53. |

When replacing components, note the different designs! Ensure

the part and list numbers are correct.

|

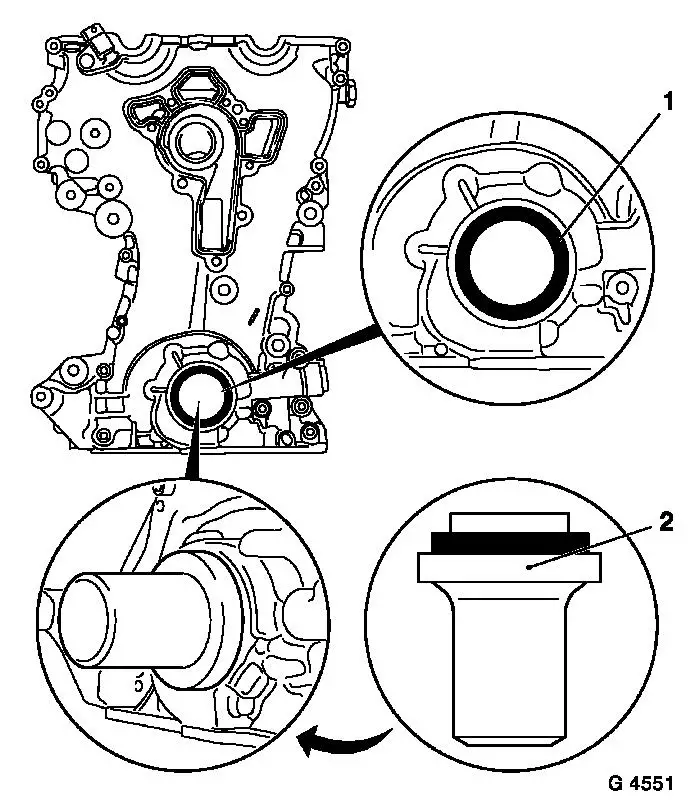

| 54. |

Replace crankshaft front seal ring (1)

| • |

Coat sealing lips with silicon grease (white)

|

| • |

Drive in until flush using KM-960

|

|

|

|

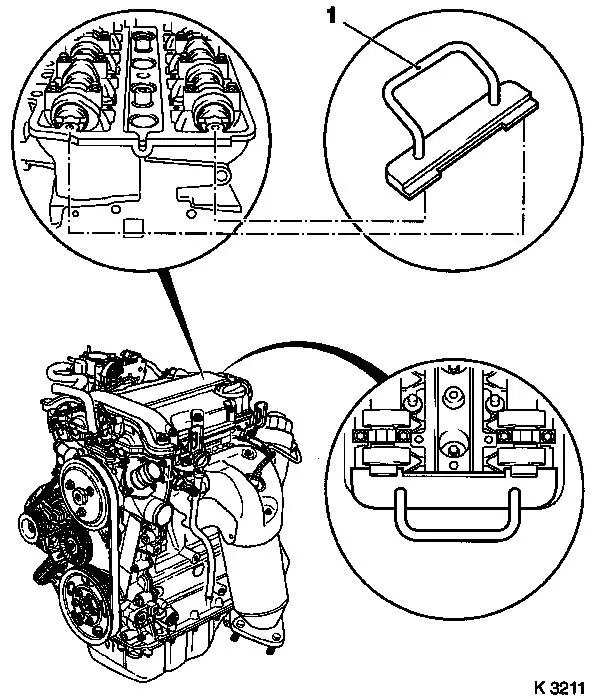

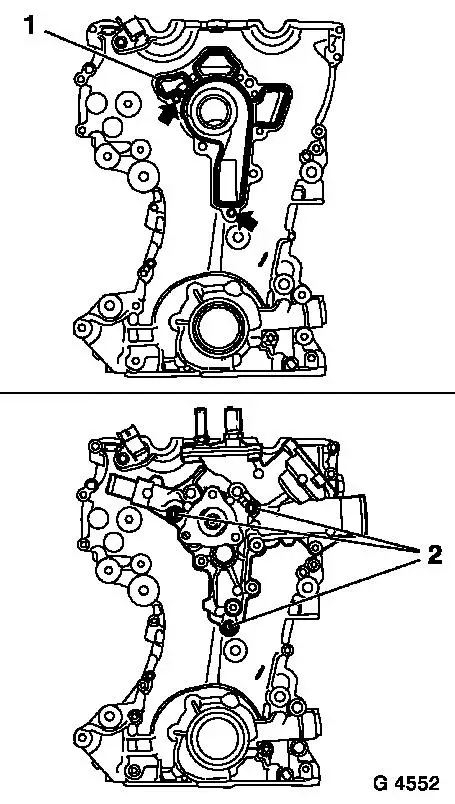

| 55. |

Replace timing case gasket

| • |

Apply silicone sealant to joint between cylinder block and

crankshaft bearing bridge

Note: Complete assembly

operations within 10 minutes

|

| • |

Cut off excess elastomer of cylinder head gasket (1) and

replace with a 2 mm thick bead of silicone sealant (2)

Note: If no excess

elastomer is present, the bead of silicone sealant can be applied

directly

|

|

|

|

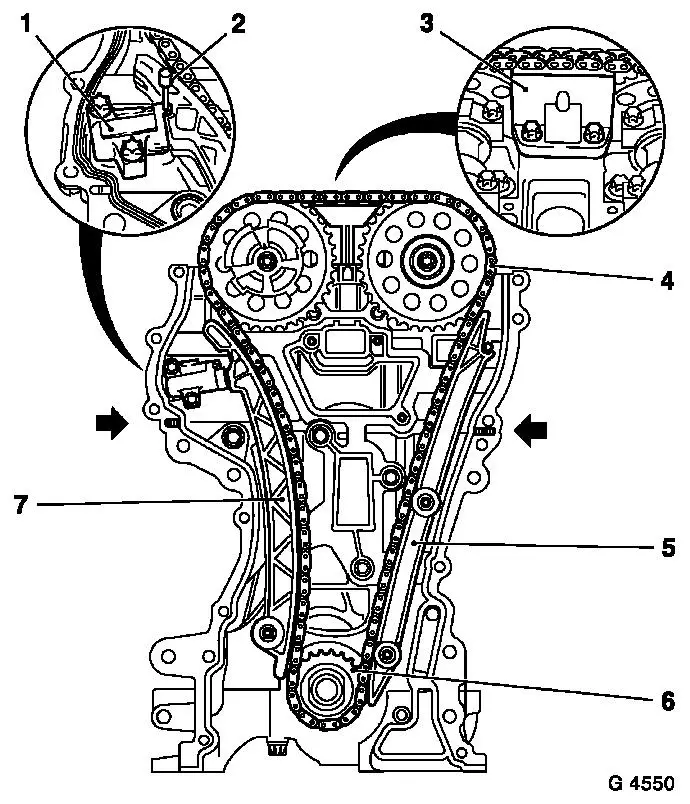

| 56. |

Attach timing chain

Note: Ensure that guide

sleeves are correctly seated (arrows)

| • |

Attach exhaust camshaft sprocket

|

| • |

Install timing chain (3)

|

| • |

Insert intake camshaft sprocket with phase sensor disc in

timing chain

| – |

Bolt in bolt

Note: It must be

possible to rotate phase sensor disk by hand

|

|

|

|

|

| 57. |

Attach timing chain tension rail (6)

| • |

Tighten bolt 20 Nm

Note: Ensure that

timing chain is correctly seated

|

|

| 58. |

Attach timing chain guide rail (4)

Note: Ensure that

timing chain is correctly seated

|

| 59. |

Attach timing chain sliding rail (2)

|

|

| 61. |

Attach coolant pump

Note: Ensure that guide

sleeves are correctly seated (arrows)

| • |

Attach using short bolts (2)

|

|

|

|

|

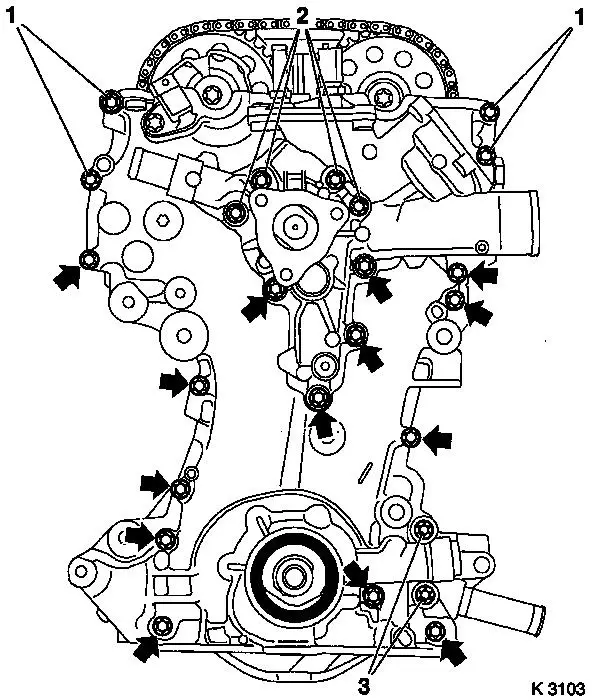

| 62. |

Attach timing case.

Note: Note tightening

sequence.

| • |

Tighten 5x bolts (1) (M6) 8 Nm

|

| • |

Tighten 14x bolts (2) (M6) 8 Nm

|

| • |

Tighten 2x bolts (3) (M10) 35 Nm

|

|

| 63. |

Install coolant connection

|

|

| 65. |

Remove KM-952

Note: Retaining tools

must not be used for counterholding

|

| 66. |

Attach crankshaft hub (1)

Note: Note crankshaft

hub installation position - mark must point upwards

|

| 67. |

Tighten crankshaft hub bolt

Note: Second person

required

| • |

Counterhold with KM-956-1 / KM-956-2 (2)

|

| • |

Tighten bolt 150 Nm + 45°

|

| • |

Detach KM-956-1 / KM-956-2

|

|

| 68. |

Attach crankshaft ribbed V-belt pulley

| • |

Counterhold at crankshaft hub bolt

|

|

|

|

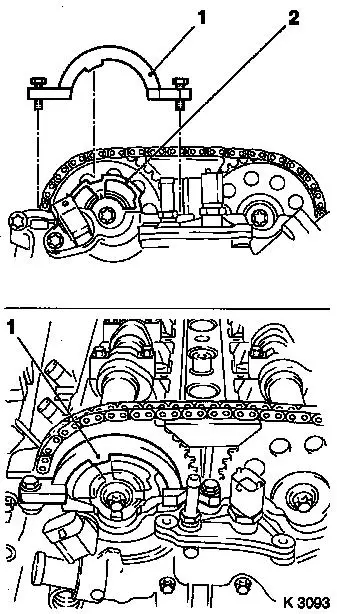

| 71. |

Attach KM-954 (1)

| • |

Rotate phase sensor disk (2) until KM-954 can be attached to timing case

|

|

|

|

| 72. |

Fasten camshaft sprockets

Note: First tighten

intake camshaft sprocket bolt

| • |

Tighten 2x bolts (2) 10 Nm

Note: Tightening torque

of 10 Nm is used to secure the

camshaft sprockets and the phase sensor disk

| – |

Counterhold camshafts at hexagonal section (1)

|

|

|

| 73. |

Remove retaining tools

Note: Retaining tools

must not be used for counterholding

| • |

KM-952 , KM-953 , KM-954

|

|

| 74. |

Fasten camshaft sprockets

Note: Second person

required

| • |

Tighten bolts 50 Nm + 60°

Note: First tighten

intake camshaft sprocket bolt

| – |

Counterhold camshafts at hexagonal section

|

|

|

|

|

| 76. |

Remove retaining tools

| • |

KM-952 , KM-953 , KM-954

|

|

| 77. |

Attach ribbed V-belt tensioner

| • |

Tighten bolt (M10) 55 Nm

|

|

| 78. |

Attach coolant pump ribbed V-belt pulley

|

| 79. |

Install ribbed V-belt

Note: Note running

direction

|

| 80. |

Install right engine bracket

| • |

Tighten 2x upper bolts 60 Nm

|

| • |

Fasten engine damping block

|

|

| 82. |

Fit compressor

| • |

Connect wiring harness plug

|

|

| 83. |

Fasten right engine bracket

| • |

Tighten lower bolt 60 Nm

|

|

| 87. |

Attach closure bolt of crankshaft bearing bridge

|

| 88. |

Attach oil pan

Note: Note tightening

sequence.

| • |

On crankshaft bearing bridge

| – |

Tighten 14x bolts 10 Nm

|

|

|

| 89. |

Install alternator

| • |

Tighten 2x bolted connections 35

Nm

|

|

| 90. |

Screw on alternator wiring harness

|

| 91. |

Install ribbed V-belt tensioner

| • |

Tighten bolt (M8) 20 Nm

|

| • |

Tighten bolt (M10) 55 Nm

|

| • |

Tension ribbed V-belt tensioner in direction of arrow with

KM-6131

|

| • |

Release ribbed V-belt tensioner

|

|

| 92. |

Install ribbed V-belt

Note: Note running

direction

| • |

Tension ribbed V-belt tensioner with KM-6131

|

| • |

Release ribbed V-belt tensioner

|

|

| 93. |

Attach exhaust system

| • |

Connect oxygen sensor (catalytic converter control) wiring

harness plug.

|

|

| 94. |

Install ribbed V-belt cover

Note: With "ECO" model

variant - install lower engine compartment cover

|

| 96. |

Attach front right wheel

|

| 98. |

Fasten right front wheel

|

| 99. |

Attach cylinder head cover (1)

Note: Complete assembly

operations within 10 minutes

| • |

Apply sealant (dimension I = 2 mm)

|

| • |

Attach engine vent hose

|

|

| 100. |

Install ignition module

| • |

Connect wiring harness plug

|

| • |

Fit ignition module cover

|

|

| 101. |

Connect wiring harness for engine management

| • |

Connect 3 wiring harness plugs

|

|

| 102. |

Connect lower radiator hose

|

| 103. |

Install upper radiator hose

|

| 104. |

Attach heater supply hose

|

| 105. |

Attach preheater hose for throttle body

|

|

|

| 106. |

Install air cleaner housing

| • |

On Z 10 XEP: Fit air intake hose

|

| • |

Attach engine vent hose

|

| • |

Connect 2 wiring harness plugs

|

|

| 108. |

Fill and bleed cooling system

|

| 109. |

Top up engine oil

| • |

Observe specified engine oil quantity

|

| • |

Start engine and allow to run until oil pressure telltale

extinguishes.

|

| • |

Check engine oil level, if necessary correct.

|

|

| 110. |

Program volatile memory

|

|