|

J491700 Injection Pump, Replace (Y 17 DTL, without

AC, LHD)

Note: KM-6394 must be used from model year 04 instead of

KM-6169-1 .

|

1. Open bonnet

|

|

Caution!

On vehicles from model year 04 with ESP - the steering angle

sensor loses its basic adjustment each time the battery is

disconnected. It must be recalibrated.

2. Disconnect battery

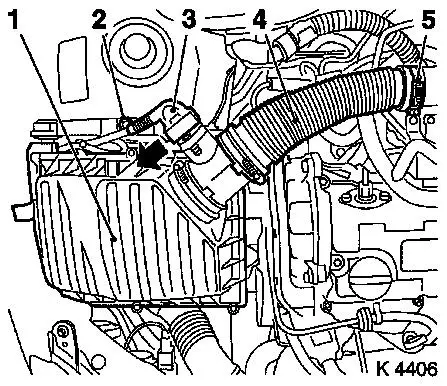

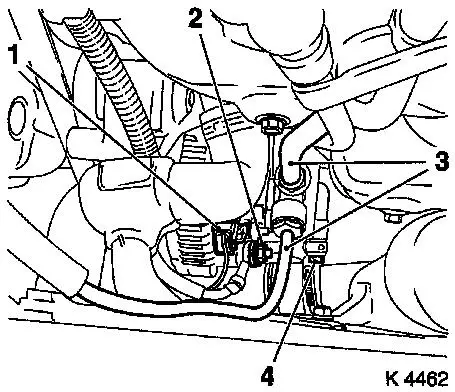

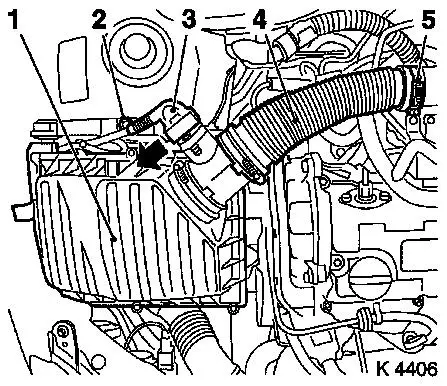

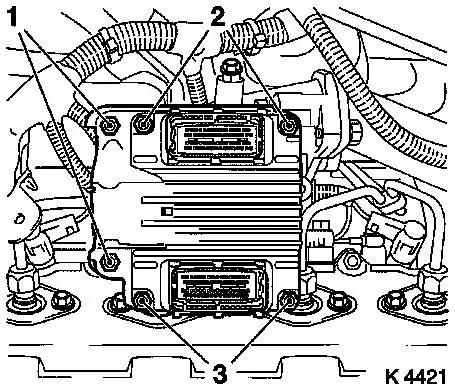

3. Remove air cleaner housing (1)

- Remove wiring harness plug for hot film mass air flow meter

(3)

- Release in direction of arrow

- Remove air intake hose (4)

- Remove bolt (2)

4. Loosen front right wheel

5. Raise vehicle

6. Remove front right wheel

7. Raise vehicle

|

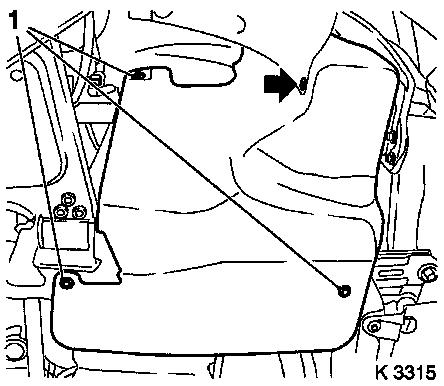

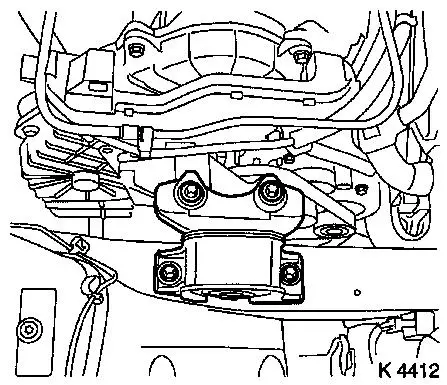

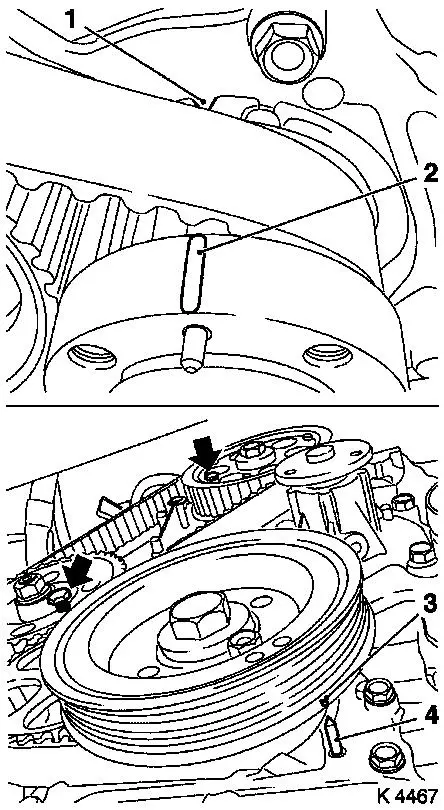

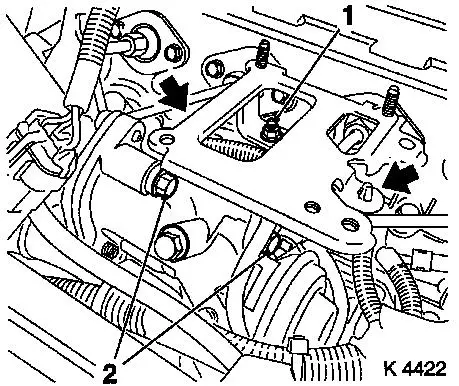

8. Remove ribbed V-belt cover

- Remove 3 bolts (1)

- Remove clip (arrow).

|

|

|

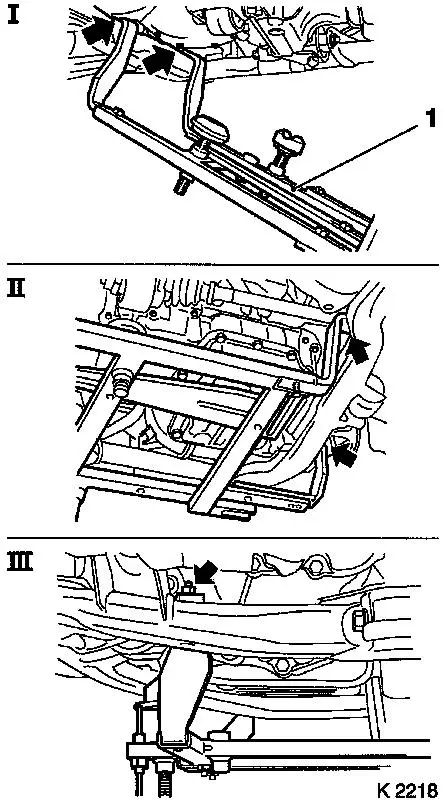

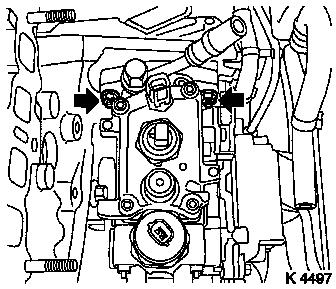

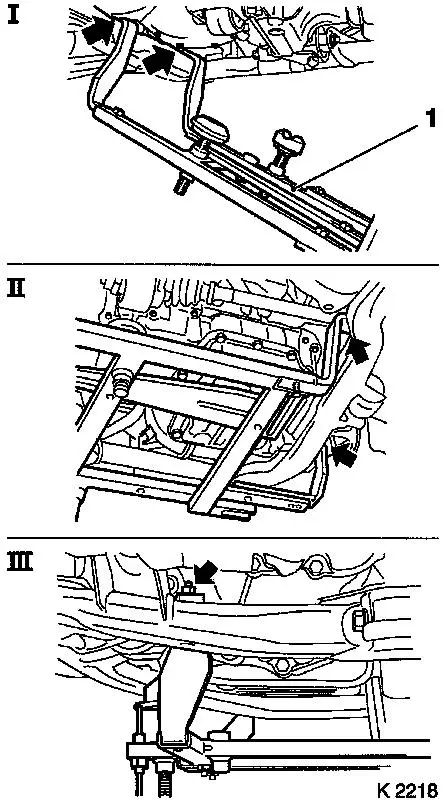

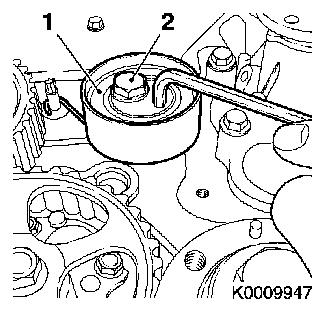

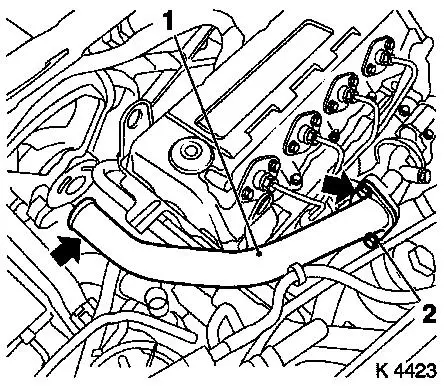

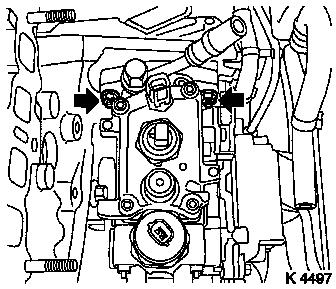

9. Attach KM-6169 (1)

- Place left of KM-6169 onto front axle body (arrows, illus.

I)

- Note! Guide pin must be seated in bore in front axle body

- Attach both right holders on the front axle body (arrows,

Illus. II).

- Note! Guide pin must be seated in bore in front axle body

(arrow, Illus. III)

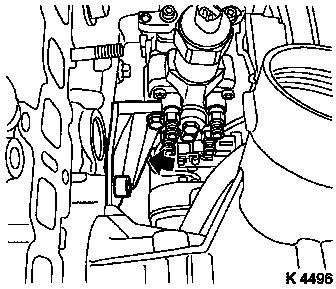

- Tighten bolts

|

|

|

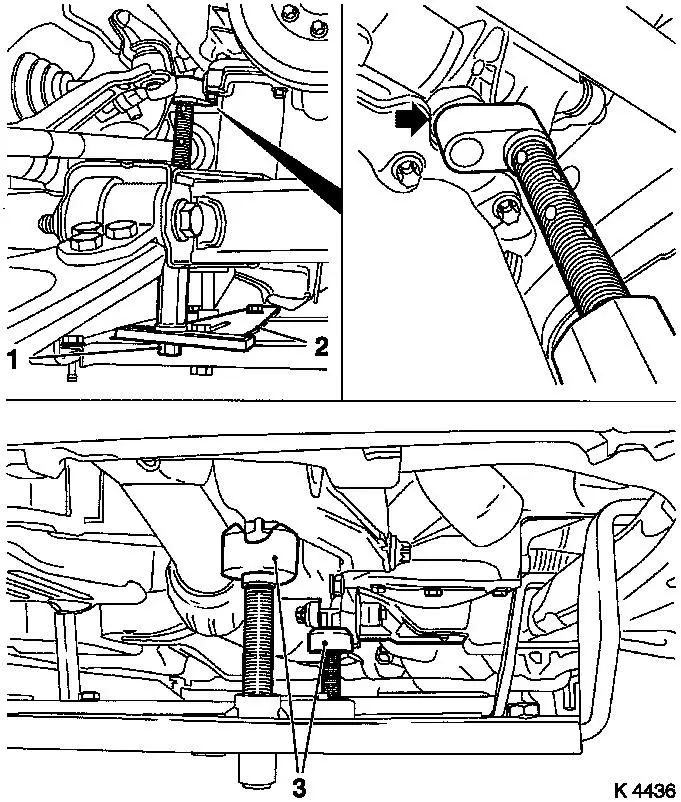

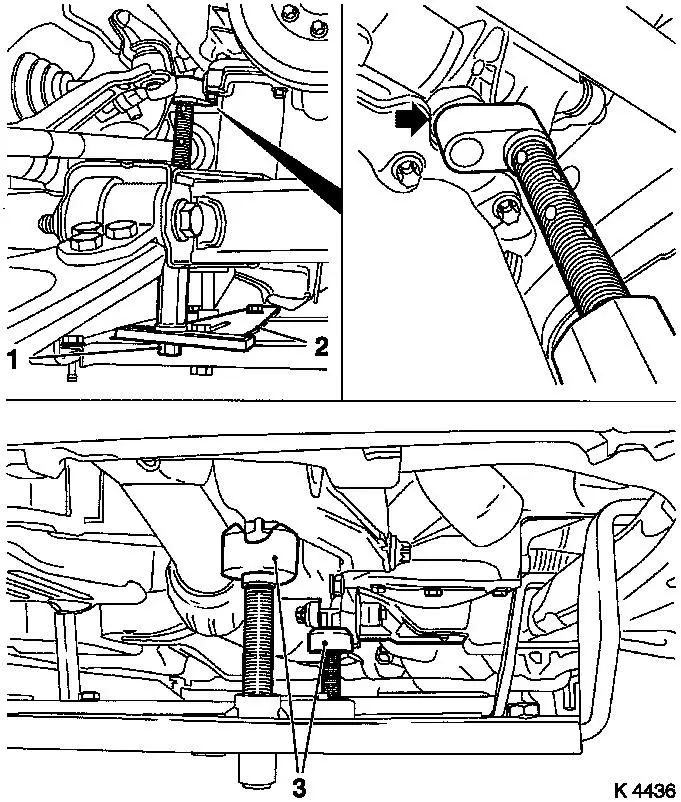

10. Install support

- To KM-6169

- Adjust bracket (2) for support

- Screw on nut (1)

|

|

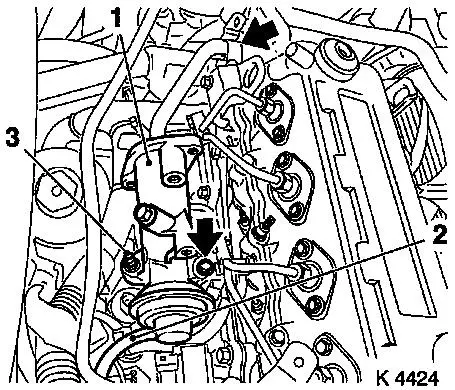

11. Adjust supports

- Transmission side

- Note! Turn spindles until the mounts (3) are positioned at the

guide journals free of play

- Engine timing side

- Insert support pin in cylinder block bore without play

(arrows)

- Tighten nuts (1)

12. Lower vehicle

|

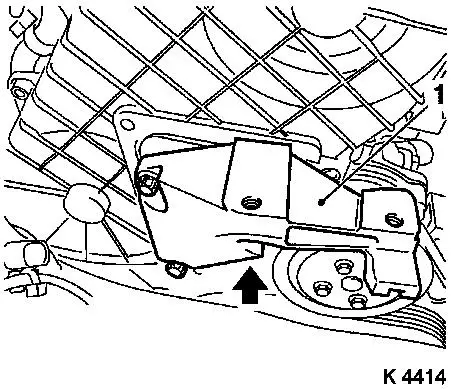

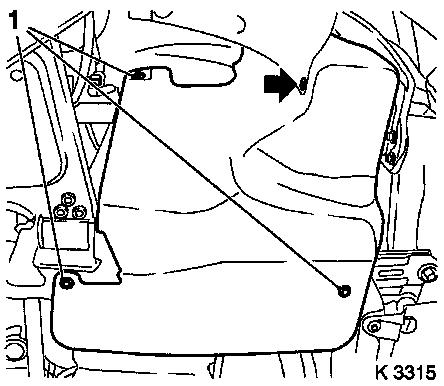

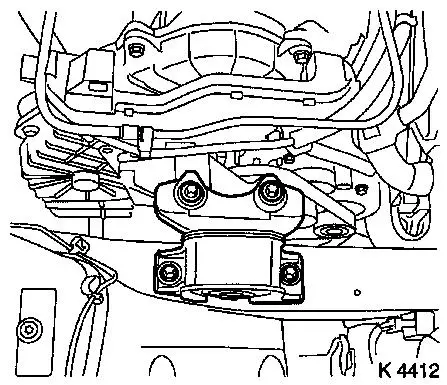

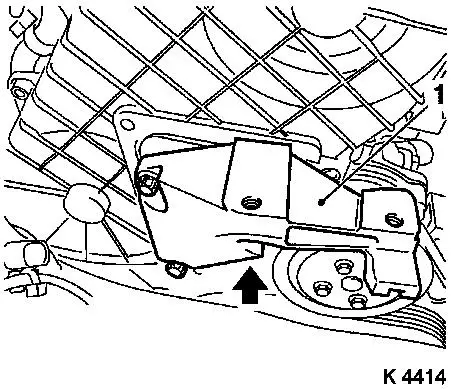

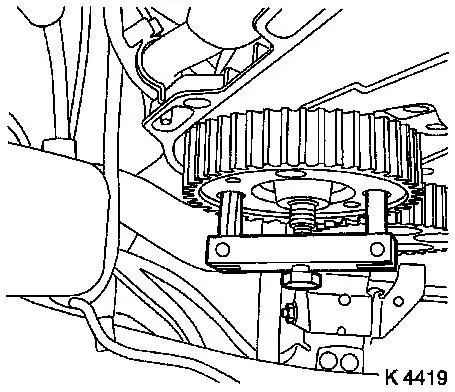

13. Remove right engine damping

block

|

|

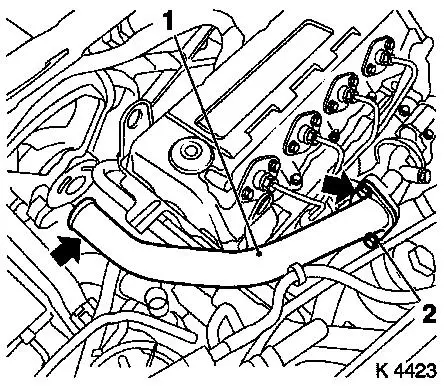

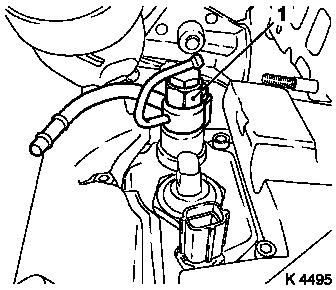

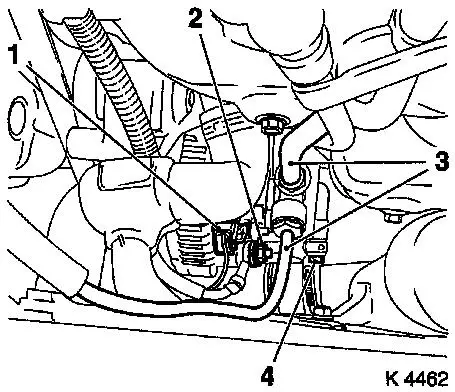

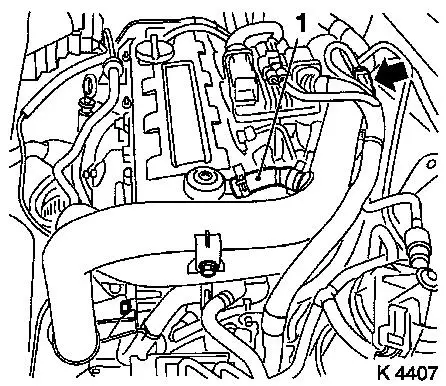

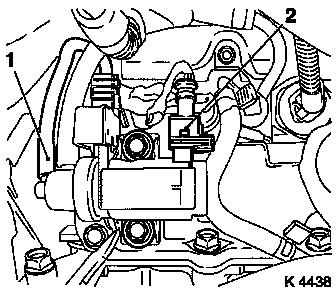

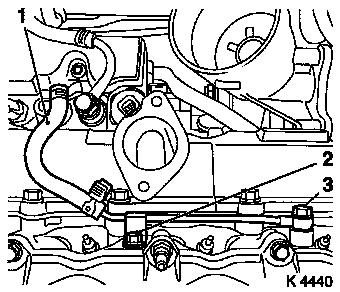

14. Detach alternator wiring

harness

- Disconnect wiring harness plug (1)

- Unscrew nut (2)

|

15. Detach vacuum hoses from vacuum

pump (3)

- Brake servo

- Exhaust gas recirculation solenoid valve

|

|

|

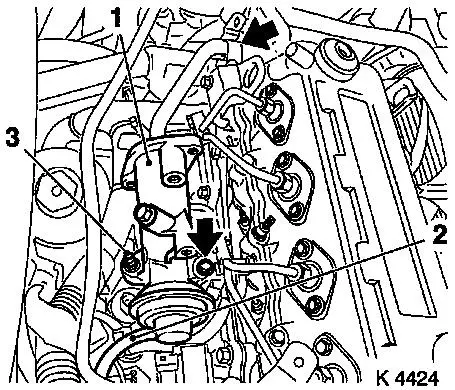

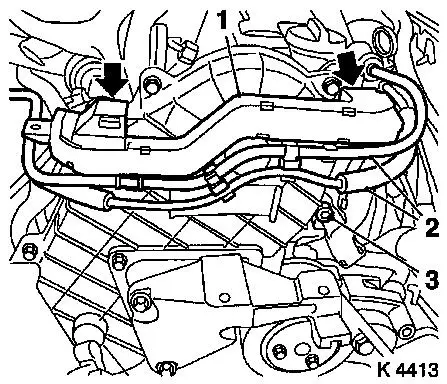

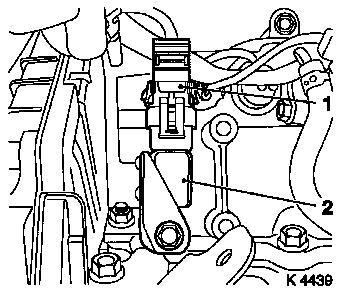

16. Remove wiring trough (1)

- Unclip vacuum lines (2)

- Unclip wiring trough

- Remove bolt (3)

|

|

|

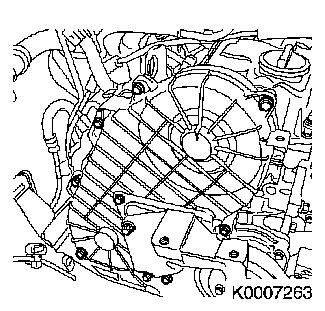

17. Loosen upper part of toothed belt

cover

- Remove 8 bolts

- Note! Note dissimilar bolt lengths

|

|

|

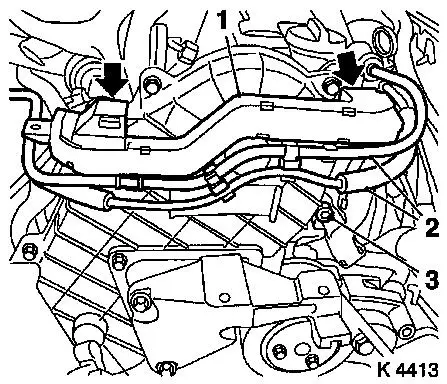

18. Detach right engine bracket (1)

- Remove 3 bolts

- Remove right engine bracket, right engine bracket adapter,

upper part of toothed belt cover

|

|

19. Raise vehicle

|

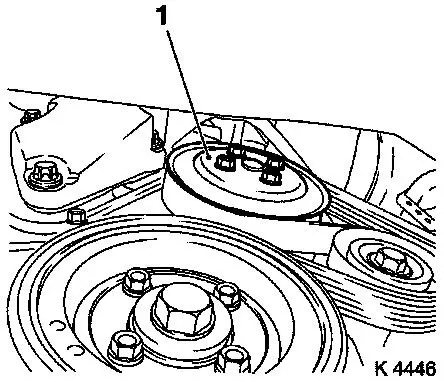

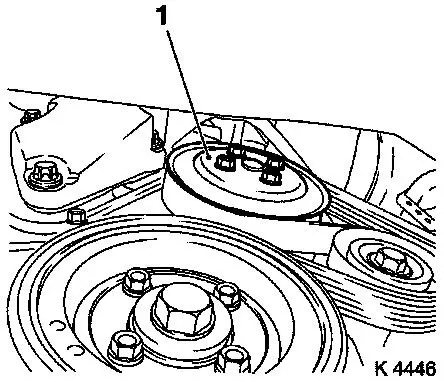

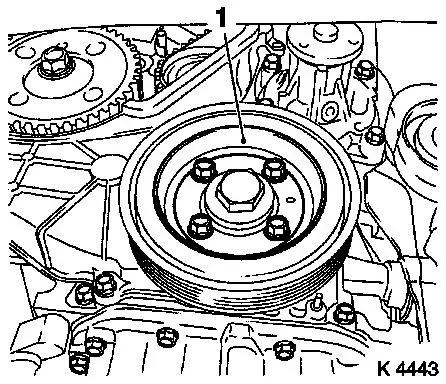

20. Loosen coolant pump ribbed V-belt

pulley (1)

|

|

21. Remove ribbed V-belt

- Tension ribbed V-belt tensioner in direction of arrow

- With KM-913-A

- Note! Mark running direction

22. Detach coolant pump ribbed V-belt

pulley

|

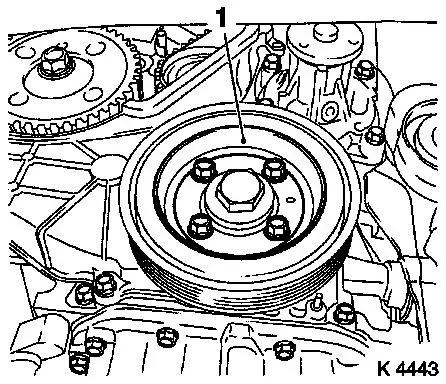

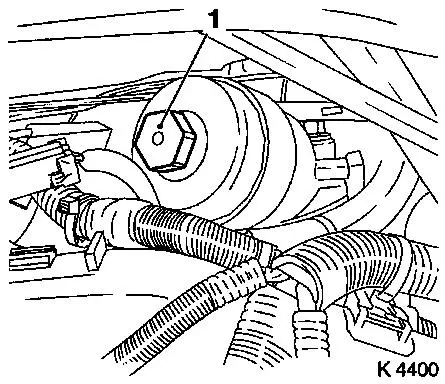

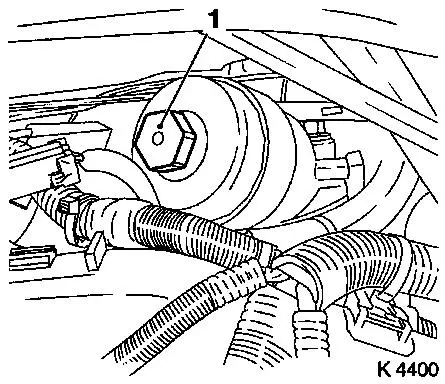

23. Remove torsional vibration damper

(1)

|

|

|

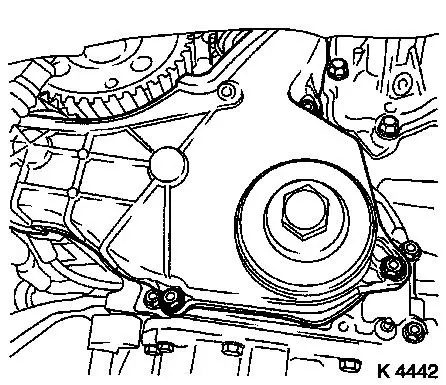

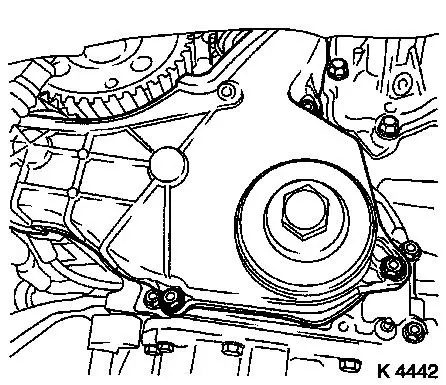

24. Detach lower part of toothed belt

cover

|

|

|

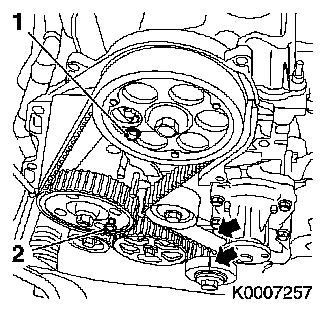

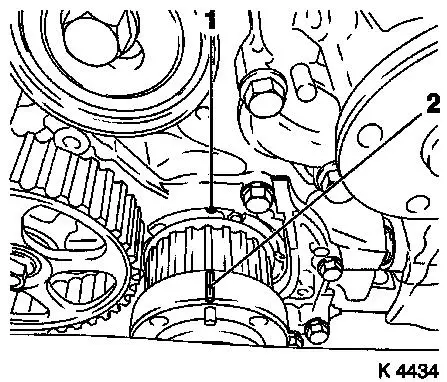

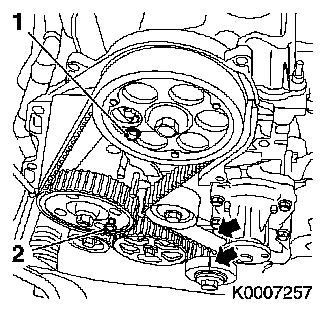

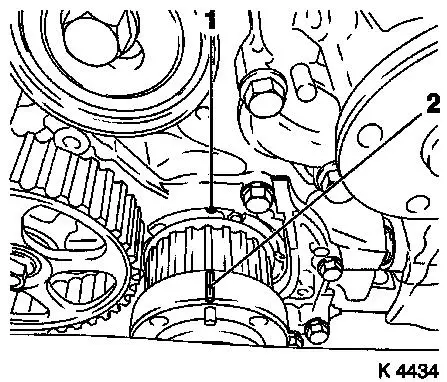

25. Set 1st cylinder to TDC

- Turn crankshaft evenly until TDC-fixing bolts can be

inserted

- Camshaft gear (M6) (1)

- Injection pump gear (M8) (2)

- Note! The mark on toothed belt drive gear must align with lug

on oil pump cover (arrows)

|

|

26. Lower vehicle

|

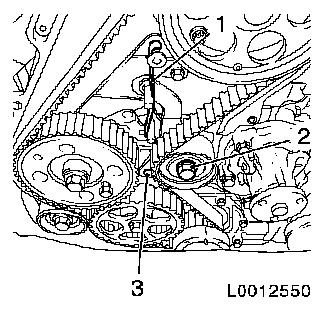

27. For toothed belt tension roller

with leaf spring:

- loosen toothed belt tensioner

- Screw in bolt (M10) in lower bore (3) of toothed belt

tensioner

- Loosen bolt (2)

- Remove tension spring (1)

|

|

|

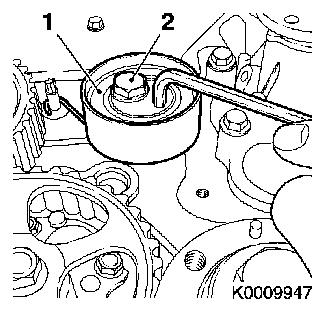

For toothed belt tension roller with

spiral spring:

- Loosen toothed belt tension roller (1)

- Rotate toothed belt tension roller anticlockwise approx.

90°

- Tighten bolt (2)

|

|

28. Remove toothed belt

- Mark direction of rotation

|

29. Remove injection pump gear

- Unscrew nut

- Unscrew TDC-fixing bolt

- Attach KM-6099

- Pull off injection pump gear

- Note! Note woodruff key

|

|

|

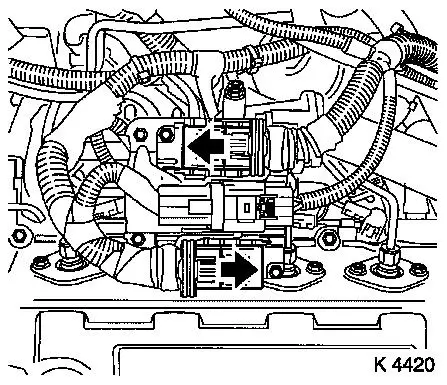

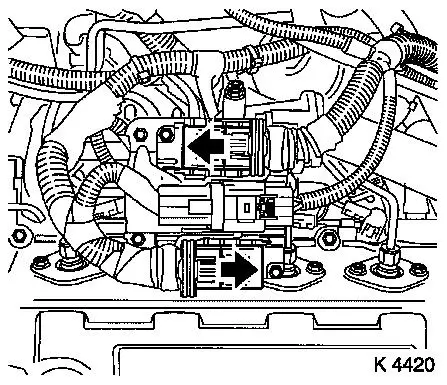

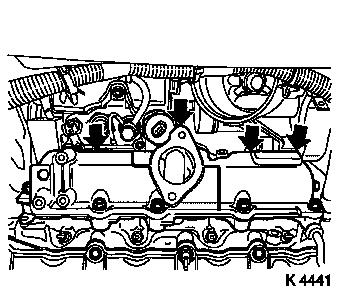

30. Remove wiring harness plug for

engine control unit

- 3 off

- Release 2 wiring harness plugs in direction of arrow

- Unclip wiring harness

|

|

|

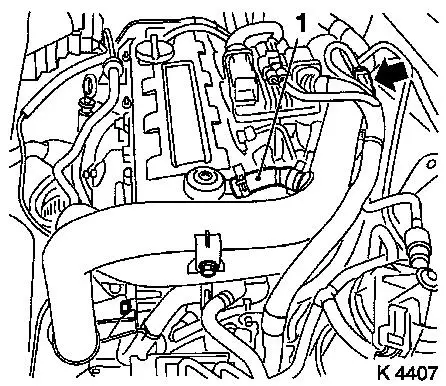

31. Remove air intake pipe

- Remove 3 bolts

- Remove vent hose (1)

- Detach air intake pipe from turbocharger

|

|

32. Remove charge air hose

- From turbocharger, centre charge air pipe

|

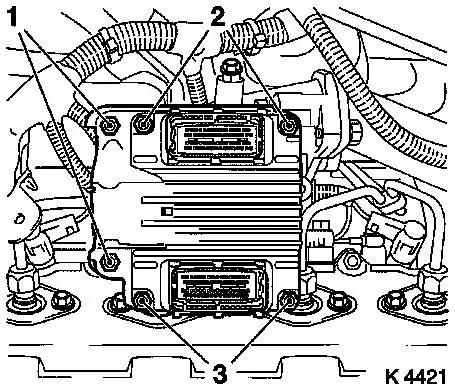

33. Remove engine control unit

- Unclip wiring harness for engine management

- Remove wiring harness plug bracket

- Unscrew 2 bolts (2), 2 nuts (3)

|

|

|

34. Remove engine control unit

bracket

- Unscrew 2 bolts (2), nut (1)

- Unclip wiring harness (arrows)

|

|

35. Detach starter/alternator wiring

harness bracket

- From exhaust recirculation valve

- Remove 2 nuts

|

36. Remove centre charge air pipe

(1)

|

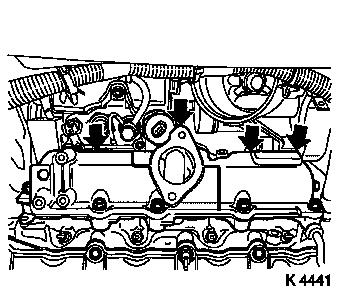

|

37. Remove wiring harness plug

- from sheathed glow plugs

- 4 off

|

38. Remove exhaust recirculation valve

(1)

- Remove exhaust recirculation pipe

- Unscrew studs (3), 2 bolts

- Detach vacuum hose (2)

- Remove gaskets

|

|

|

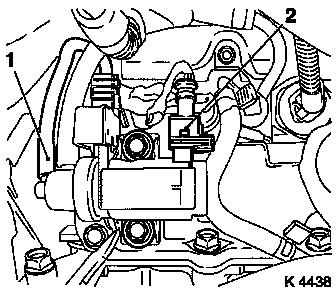

39. Remove exhaust recirculation

solenoid valve

- Detach vacuum hose (1)

- Detach wiring harness plug (2).

- Remove 2 bolts

|

|

40. Remove right rear engine transport

shackle

|

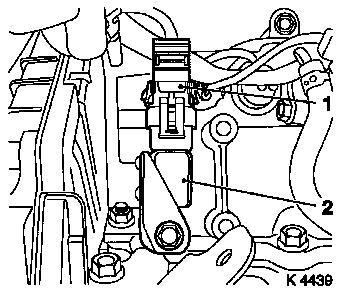

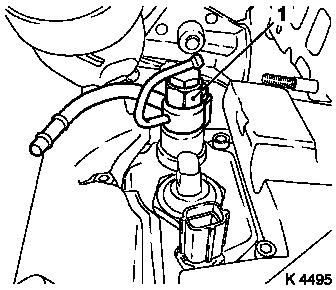

41. Remove charge pressure sensor

(2)

- Disconnect wiring harness plug (1)

- Remove bolt

|

|

|

42. Remove oil filter insert

- Place collecting basin underneath.

- Unscrew oil filter housing cover (1)

|

|

43. Detach oil return line

- From oil filter housing

- Release clamp

|

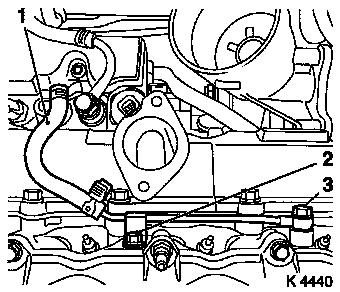

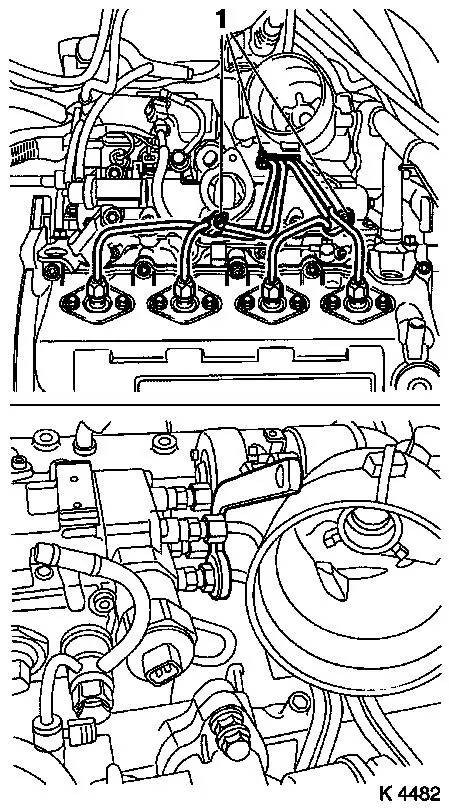

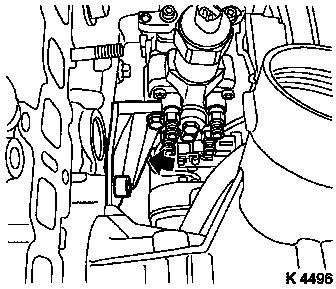

44. Remove injection line spacers

(1)

|

|

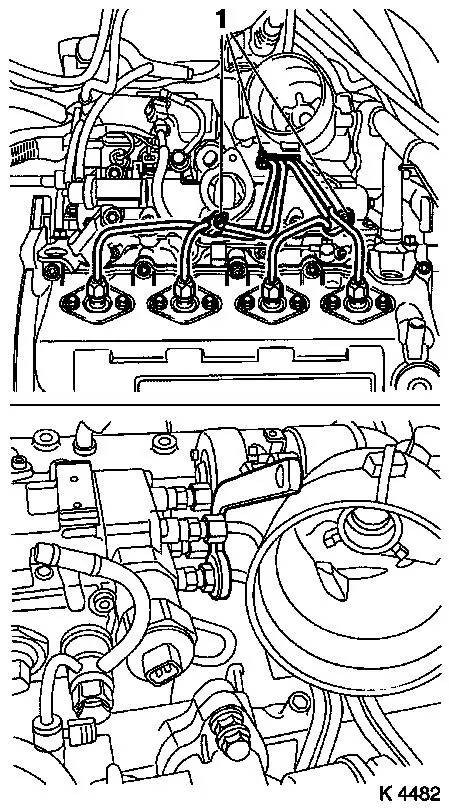

45. Remove injection lines

|

46. Detach outer oil leak line

- Unscrew 1 banjo bolt (3), 1 bolt (2)

- Remove oil leak hose (1)

|

|

47. Remove wiring harness plug

- From diesel injection pump

|

48. Remove two piece intake

manifold

- Unscrew 7 bolts, 2 nuts

- Remove gaskets

|

|

49. Remove fuel lines

- From diesel injection pump

|

50. Remove fuel return connection

- Note! Do not unscrew check valve (SW 14) from banjo bolt.

Carefully unscrew banjo bolt (1) (SW 17)

- Close off return bore using blind plugs

|

|

51. Remove outer diesel injection pump

insulation

52. Remove wiring harness for engine

management

- Disconnect wiring harness plug

- Unclip wiring harness

53. Remove inner diesel injection pump

insulation

|

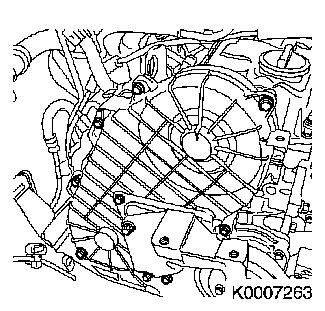

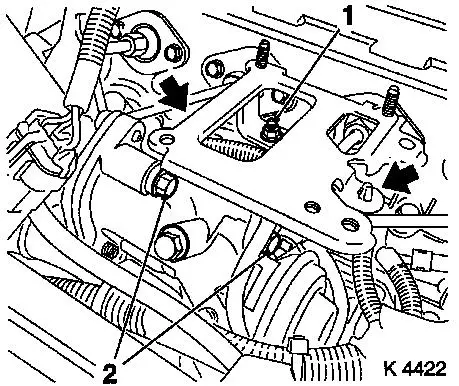

54. Remove diesel injection pump

bracket

|

|

|

55. Remove diesel injection pump

- Remove 2 nuts

- Disconnect wiring harness plug

|

|

56. Install diesel injection pump

- Insert diesel injection pump

- Connect wiring harness plug.

- Tighten 2 nuts with washers (19.6 Nm/14.5 lbf. ft.)

57. Install diesel injection pump

bracket

- Install 4 bolts

- Tighten 2 bolts at cylinder head (53.9 Nm / 39.8 lbf. ft.)

58. Install injection pump gear

Note: Observe

tightening sequence

| 1. |

Tighten nut 60 Nm

|

| 2. |

Loosen nut |

| 3. |

Waiting time: 60 sec |

| 4. |

Tighten nut 60 Nm

|

| |

o |

Install TDC-fixing bolt |

|

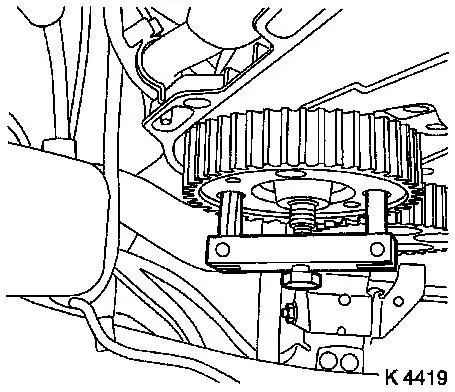

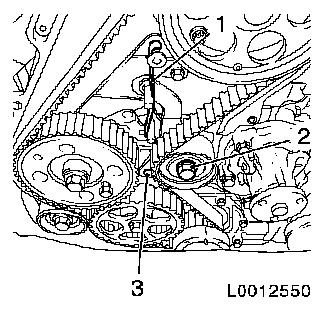

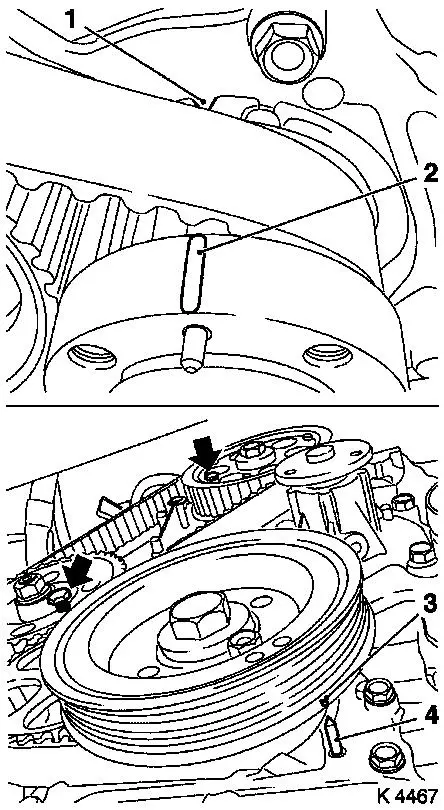

59. Check TDC position for 1st

cylinder

- Mark on toothed belt drive gear (2) must align with casting lug

at oil pump cover (1)

|

|

60. Install toothed belt

Note: Toothed belt

must be taut from toothed belt drive gear via oil pump drive gear

and injection pump drive gear

- For toothed belt tension roller with leaf spring:

- Unscrew TDC-fixing bolt

- Rotate crankshaft 60° against direction of engine

rotation

- Tighten bolt of toothed belt tension roller

- For toothed belt tension roller with spiral spring 49 Nm

- For toothed belt tension roller with leaf spring 38.2 Nm

61. For toothed belt tension roller with leaf spring: unscrew

bolt (M10) from lower bore of toothed belt tensioner

|

62. Timing, Check

- Turn crankshaft approx. 780° in direction of engine

rotation

- At toothed belt drive gear bolt

- Mark on toothed belt drive gear (2) must align with casting lug

at oil pump cover (1)

- Install TDC-fixing bolt

- Install torsional vibration damper

- Note! Mark on torsional vibration damper (3) must align with

pin (4) on oil pump cover If the TDC fixing bolts cannot be

inserted, the basic adjustment must be repeated

- Unscrew TDC-fixing bolts

|

|

|

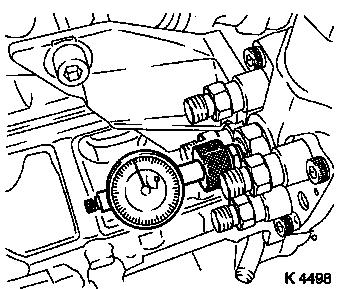

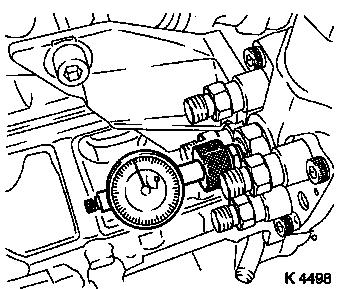

63. Attach KM-798

- Turn crankshaft in direction of engine rotation to 45°

before 1st cylinder TDC

- At toothed belt drive gear bolt

- Remove central bleeder screw

- Install KM-798 under pre-tension

- Determine BDC position of injection pump plunger by turning

crankshaft back and forth

- Note! The dial gauge indicator must not move

- Set dial gauge to "0".

|

|

64. Adjust diesel injection pump

- Turn crankshaft to 1st Cylinder TDC

- Note! The pin on the oil pump must align with the mark on the

pulley

- Loosen diesel injection pump

- Turn diesel injection pump until 0.33 mm adjustment value is

accomplished

- Value too high – turn injection pump towards engine.

- Value too low – turn injection pump away from

engine.

- Tighten diesel injection pump (19.6 Nm / 14.4 lbf. ft.)

65. Check start of feed

- Remove KM-798

- Turn crankshaft approx. 675°

- Install KM-798 under pre-tension

- Determine BDC position of injection pump plunger by turning

crankshaft back and forth

- Note! The dial gauge indicator must not move

- Set dial gauge to "0".

- Turn crankshaft to 1st Cylinder TDC

- Note! The pin on the oil pump must align with the mark on the

pulley

- Read test value

- Test value: 0.28 – 0.38 mm

- Caution! If test value is not achieved, adjustment must be

repeated

66. Remove KM-798

- Remove dial gauge

- Tighten centre bleeder screw (25 Nm / 18.4 lbf. ft.)

67. Install diesel injection pump

bracket

- Tighten 2 bolts (18.6 Nm / 13.7 lbf. ft.)

68. Remove torsional vibration

damper

69. Insert inner diesel injection pump

insulation

70. Attach wiring harness for engine

management

- Connect wiring harness plug.

- Attach wiring harness

71. Install outer diesel injection pump

insulation

72. Attach fuel line connection

73. Attach fuel lines

74. Clean sealing surfaces

75. Install two piece intake

manifold

- Replace gaskets

- Tighten bolts, nuts (24.5 Nm/18.7 lbf. ft.)

76. Connect wiring harness plug

77. Install outer oil leak line

- Renew seal rings

- Tighten bolt, banjo bolt (14.7 Nm / 10.8 lbf. ft.)

- Install oil leak hose

78. Install injection lines

- Caution! Injection lines must be installed without tension.

Hand-tighten at injector nozzles and injection pump.

- Tighten union nuts (22.5 Nm/16.6 lbf. ft.)

79. Install injection line spacers

- Note! Note spacer positions

- 3 off

80. Attach oil return line

81. Install oil filter insert

- Replace seal ring

- Tighten oil filter housing cover (25 Nm/18.5 lbf. ft.)

82. Install charge control sensor

- Tighten bolt (9.8 Nm / 7.2 lbf. ft.)

- Connect wiring harness plug.

83. Install exhaust recirculation

solenoid valve

- Rework threads

- Tighten 2 bolts

- Insert bolts with locking compound

- Connect wiring harness plug.

- Connect vacuum hose.

84. Install right rear engine transport

shackle

- Tighten bolt (20 Nm / 15 lbf. ft.)

85. Install exhaust recirculation

valve

- Clean sealing surfaces.

- Insert exhaust recirculation valve

- Tighten studs, 2 bolts (24.5 Nm/18.1 lbf. ft.)

- Replace gasket

- Connect vacuum hose.

- Attach exhaust gas recirculation pipe

- Tighten 2 bolts (28.4 Nm / 21 lbf. ft.)

- Replace gasket

86. Install centre charge air pipe

- Clean sealing surface

- Tighten studs, 2 bolts

- Replace gasket

87. Attach starter/alternator wiring

harness bracket

88. Attach wiring harness plug

89. Install engine control unit

bracket

- Tighten 2 bolts (24.5 Nm / 18 lbf. ft.)

- Tighten nut (9.8 Nm/7.2 lbf. ft.)

- Clip in wiring harness

90. Install engine control unit

- Install engine control unit

- Tighten 2 bolts, 2 nuts (5.9 Nm/4.4 lbf. ft.)

- Install wiring harness plug bracket

- Connect wiring harness plug.

91. Install air intake pipe

- Tighten 3 bolts

- Fasten hose clamp

- Attach engine vent hose

- Attach wiring harness

92. Attach charge air hose

93. Attach engine control unit wiring

harness plug

- Route wiring harness

- Connect wiring harness plug.

- Attach wiring harness

94. Attach lower part of toothed belt

cover

- Tighten bolts (9.8 Nm / 7.2 lbf. ft.)

95. Attach right engine bracket

- Insert lower bolt

- Into right engine bracket and right engine bracket adapter

- Insert right engine bracket, right engine bracket adapter,

upper part of toothed belt cover

- Install 2 upper bolts

- Tighten 3 bolts (40 Nm / 29.5 lbf. ft.)

96. Fasten upper part of toothed belt

cover

- Tighten bolts (9.8 Nm / 7.2 lbf. ft.)

- Note! Note dissimilar bolt lengths

97. Attach coolant pump ribbed V-belt

pulley

98. Raise vehicle

99. Install torsional vibration

damper

- Tighten bolts (19.6 Nm / 14.5 lbf. ft.)

100. Install ribbed V-belt

- Note! Observe running direction and installation position

- Release ribbed V-belt tensioner

101. Fasten coolant pump ribbed V-belt

pulley

- Tighten bolts (9.8 Nm / 7.2 lbf. ft.)

102. Lower vehicle

103. Install right engine damping

block

- To side member

- Tighten bolts (40 Nm / 29.5 lbf. ft.)

- On engine bracket

- Tighten bolts (60 Nm/44 lbf. ft + 30° + 15°.)

104. Attach wiring trough

- Clip-in wiring trough

- Clip in vacuum lines

- Tighten bolt

105. Attach alternator wiring

harness

- Connect wiring harness plug.

- Tighten nuts

106. Install vacuum hoses from vacuum

pump

- Route lines and clip in

- Tighten union nut (18 Nm/13.3 lbf. ft.)

107. Install air cleaner housing

- Tighten bolt

- Fasten air intake hose.

- Connect wiring harness plug to hot film mass air flow

meter

108. Raise vehicle

109. Detach support

110. Remove KM-6169

111. Install ribbed V-belt cover

- Screw in bolts

- Install clip

112. Lower vehicle

113. Install right front wheel

114. Lower vehicle

115. Fasten right front wheel

- Tighten bolts (110 Nm / 81 lbf. ft.)

116. Connect battery

117. Calibrate steering angle sensor

Note: Rotate the

steering wheel one time from its right-hand to its left-hand

stop.

118. Top up engine oil

- Observe specified engine oil quantity

- Start engine and allow to run until oil pressure telltale

extinguishes.

- Check engine oil level, if necessary correct.

119. Program volatile memories

120. Close bonnet

|