|

Main shaft, dismantle and assemble (F13/F13

MTA)

Note: Transmission

remains installed.

Remove Remove

|

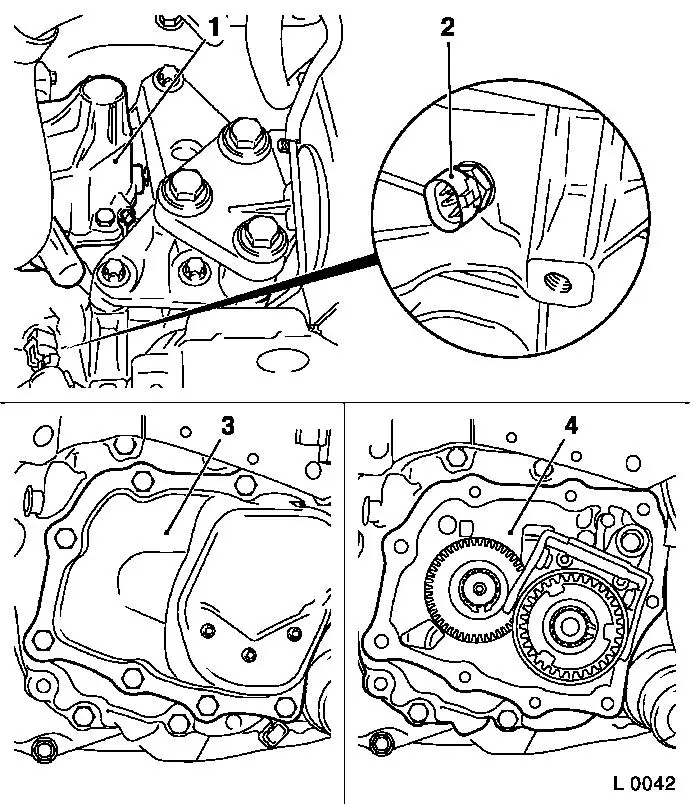

| 1. |

Remove gearshift cover (1)

|

| 2. |

Remove reversing lamp switch (2)

|

| 3. |

Remove end shield cover (3) gasket

|

| 4. |

Remove end shield (4) from transmission

|

|

|

| 5. |

Remove main shaft

Note: If the gears are

damaged, always also replace the gear cluster.

|

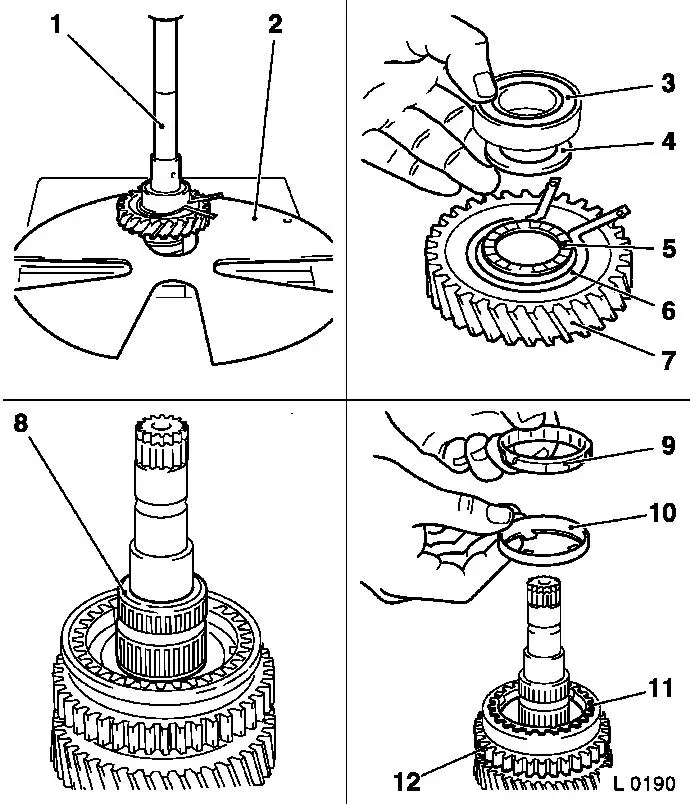

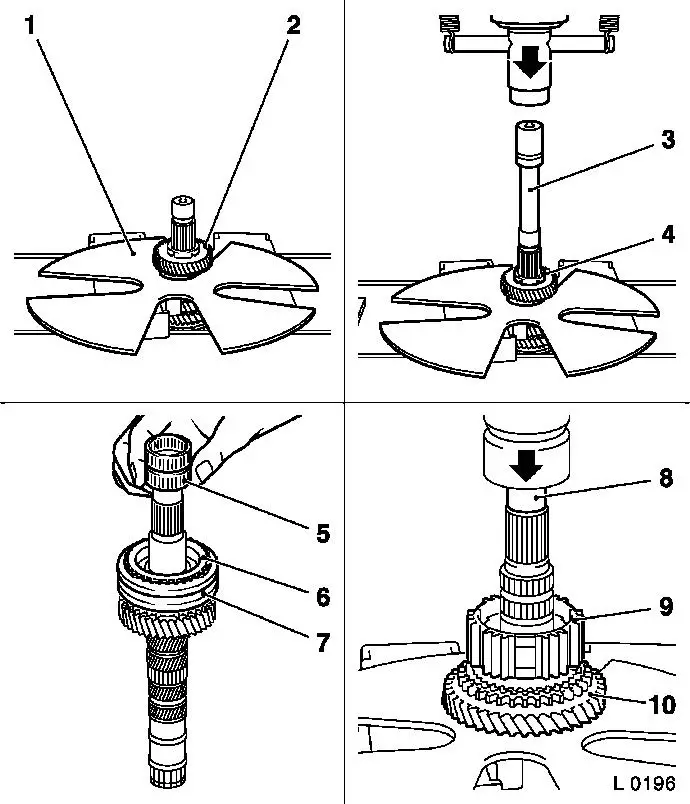

| 6. |

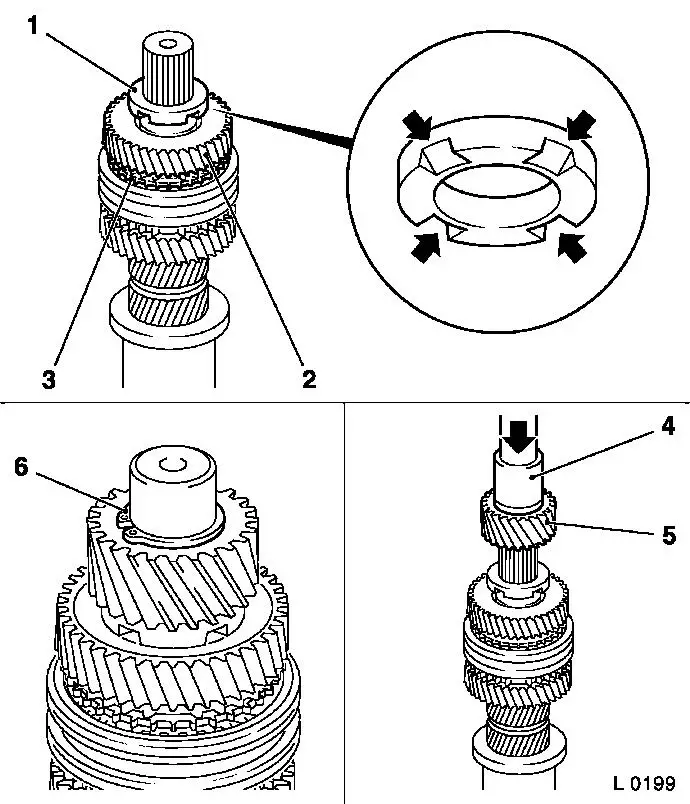

Push off ball bearing (3), spacer washer (4), retaining ring

(6), axial needle bearing (5) and 1st gear gearwheel (7) with KM-307-B (2)

|

| 7. |

Remove needle bearing (8) for 1st gear gearwheel from main

shaft

|

| 8. |

Remove inner synchro ring (9), intermediate ring (10) and outer

synchro ring (11) for 1st gear gearwheel from synchroh body

assembly (12)

|

|

|

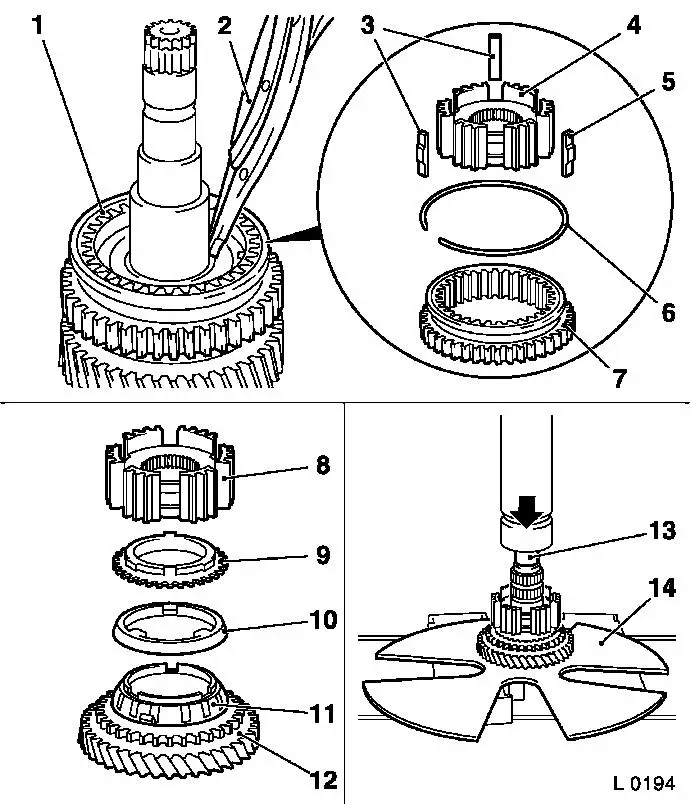

| 9. |

Remove retaining ring for 1st/2nd gear synchro body assembly

(1) with circlip pliers (2)

|

| 10. |

Remove shift sleeve (7), synchro spring (6) and sliding blocks

(3 and 5) from synchro body (4)

|

| 11. |

Push synchro body (8), inner synchro ring (9), intermediate

ring (10) and outer synchro ring (11) for 2nd gear gearwheel (12)

from main shaft with KM-307-B (14)

| • |

Use suitable drift (13)

|

|

|

|

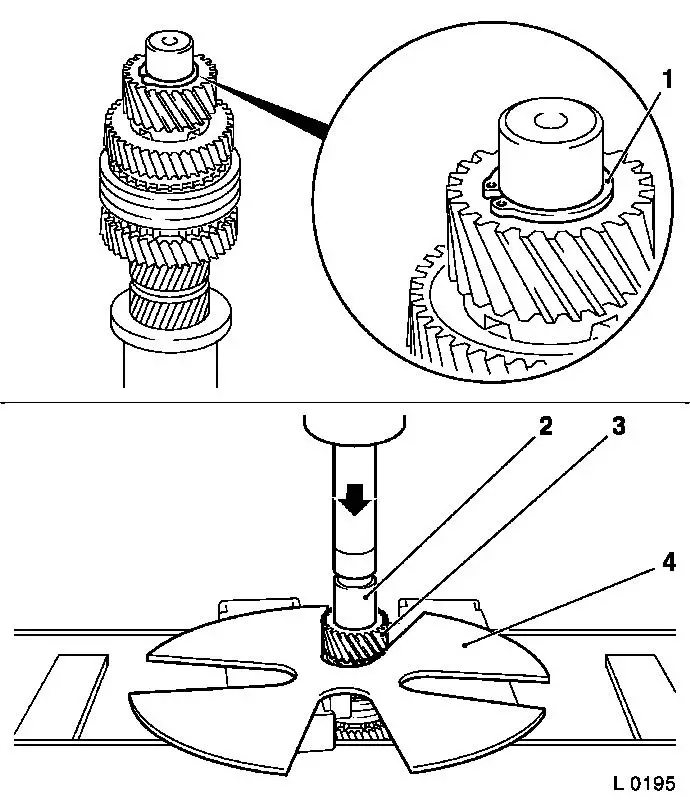

| 12. |

Remove retaining ring (1) in front of drive gear (driving) from

main shaft

|

| 13. |

Push drive gear (driving) (3) from main shaft with KM-307-B (4)

Note: Always replace

drive gears (driving and driven) in pairs

|

|

|

| 14. |

Place KM-307-B (1) in groove of 4th

gear gearwheel (2)

|

| 15. |

Push 4th gear gearwheel and spacer washer (4) from main shaft

with KM-307-B

|

| 16. |

Remove needle bearing (5) (if present), synchro ring (4th gear

gearwheel) (6), shift sleeve (7), synchro spring and sliding blocks

from main shaft

|

| 17. |

Push 3rd/4th gear synchro body (9), synchro ring and 3rd gear

gearwheel (10) from main shaft with KM-307-B

|

|

Install

Install

|

| 19. |

Immerse all parts in transmission fluid before

installation.

|

| 20. |

Check all removed parts for damage and wear, replace if

necessary

|

| 21. |

Lubricate all bearing bore holes and seating surfaces with

transmission fluid before installation.

|

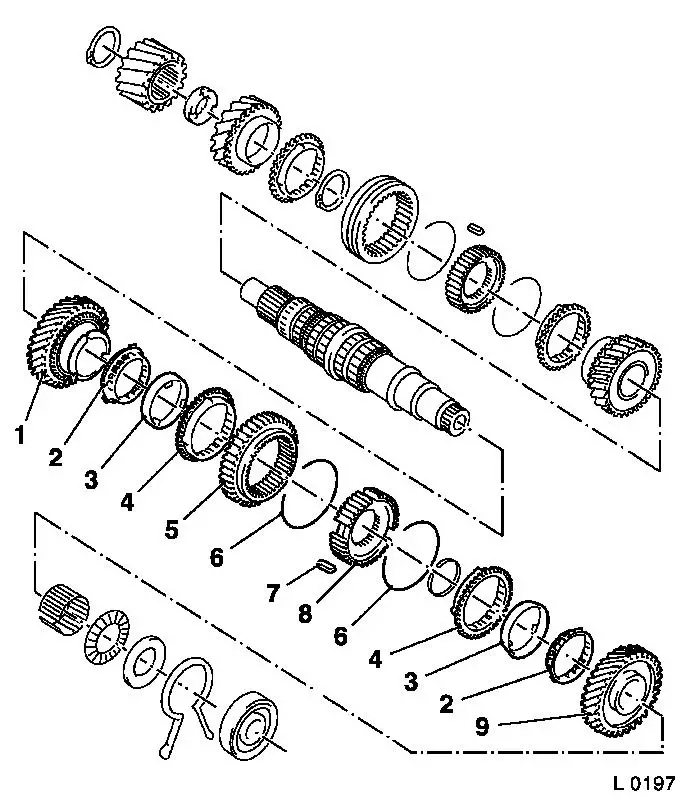

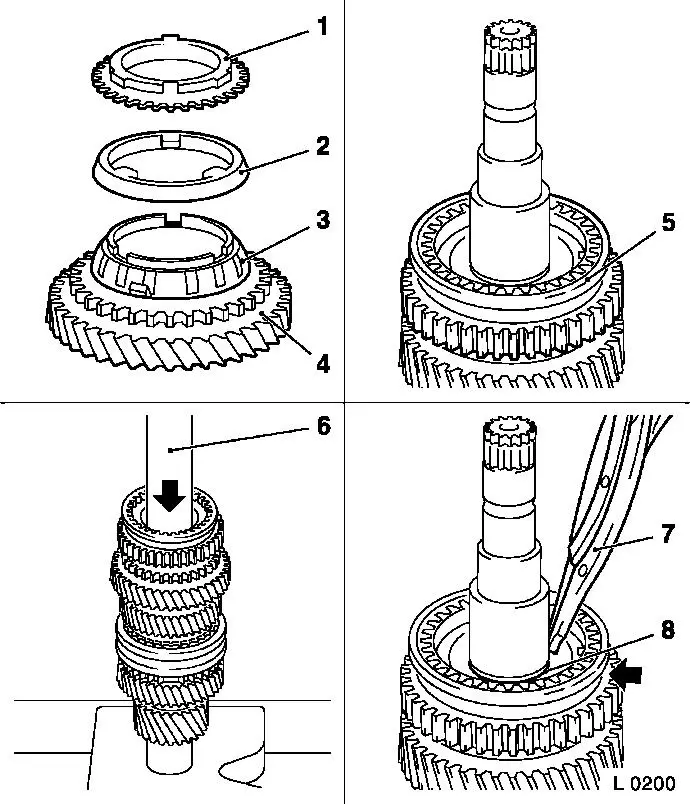

| 22. |

Transmission has 3 cone synchronisation for 1st/2nd gear:

| 1. |

2nd speed gear |

| 2. |

Inner synchroniser rings |

| 3. |

Intermediate rings |

| 4. |

Outer synchroniser rings |

| 5. |

Shift sleeve |

| 6. |

Synchroniser springs |

| 7. |

Sliders |

| 8. |

Synchromesh body |

| 9. |

1st speed gear |

|

|

|

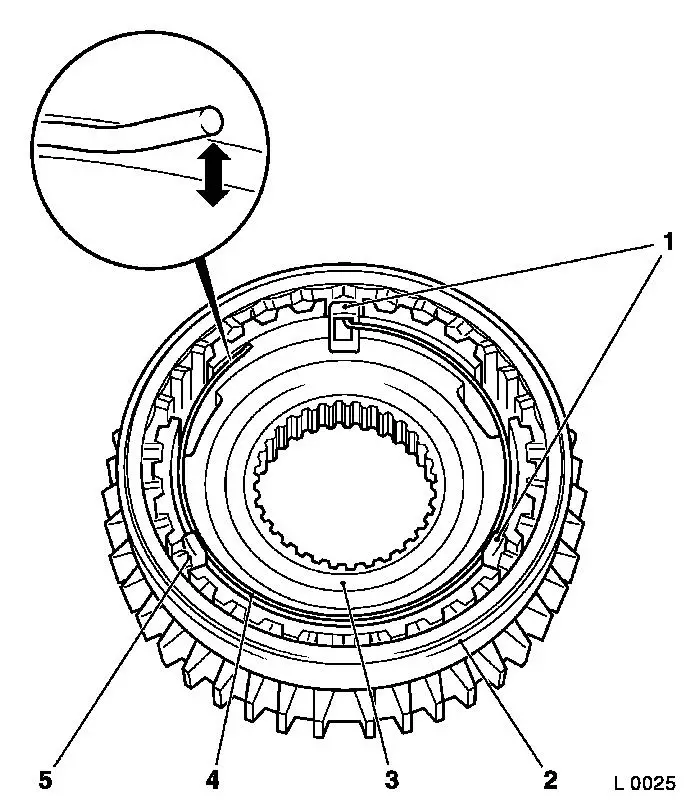

| 23. |

Insert synchro body (3) in shift sleeve (2)

Note: Synchromesh body

assembly 1st/2nd gear and 3rd/4th gear can only be pressed onto

main shaft in assembled state.

|

| 24. |

Insert sliding blocks (1) and (5)

| • |

with the open side towards the synchro body

|

|

| 25. |

Insert synchroniser spring (4)

Note: Ensure that the

free end is raised from the synchro body (arrow) in the correct

installation position. If this is not the case, turn synchro ring

by 180° and re-install.

| • |

Offset end of synchro spring engages in a sliding block

|

|

|

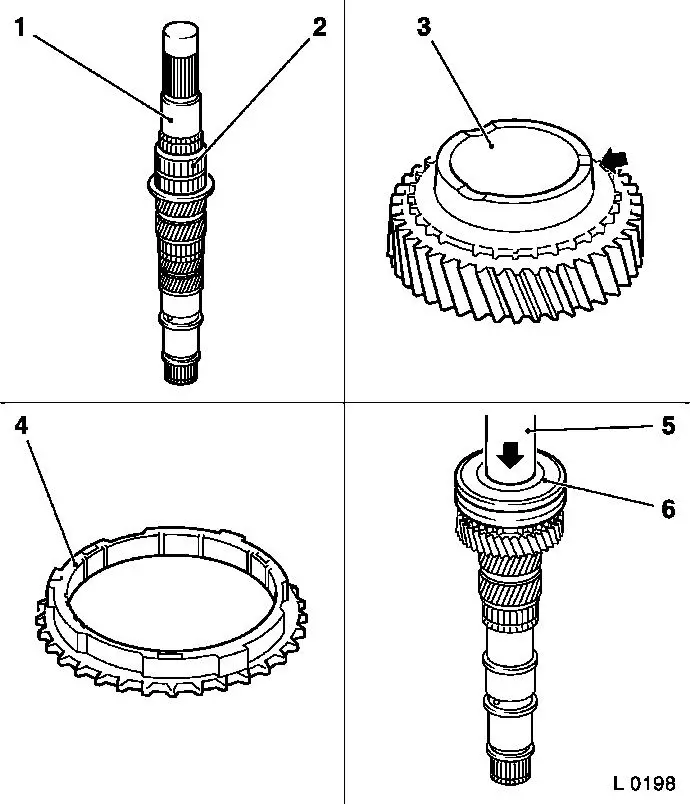

|

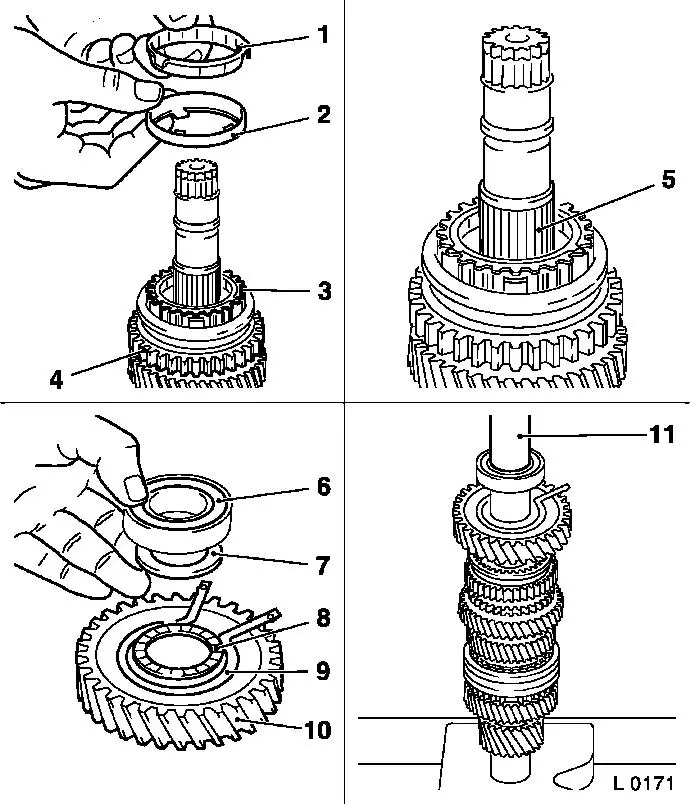

| 26. |

Attach needle bearing (2) for gear wheel, 3rd gear, to main

shaft (1)

Note: If present.

|

| 27. |

Push 3rd gear gearwheel (3) onto main shaft from drive wheel

side

| • |

Cone (arrow) points in direction of drive wheel

|

|

| 28. |

Place synchroniser ring (4) onto 3rd gear cone.

|

| 29. |

Press synchro body assembly for 3rd/4th gear (6) with KM-277 (5) onto main shaft.

|

|

|

| 30. |

Attach needle bearing, gear wheel, 4th gear to main shaft

Note: If present.

|

| 31. |

Attach synchro ring (3) and 4th gear gearwheel (2) to main

shaft

|

| 32. |

Place spacer washer (1) onto drive shaft

| • |

Four grooves (arrows) must point towards 4th gear gearwheel

|

|

| 33. |

Press drive wheel (5) onto main shaft with KM-311-2 (4)

Note: Always replace

drive gears in pairs.

| • |

Shoulder must point towards spacer washer

|

|

| 34. |

Fit new retaining ring (6) in front of drive gear

|

|

|

| 35. |

Slide 2nd gear gearwheel (4) onto main shaft

|

| 36. |

Place inner synchro ring (3) onto cone of gearwheel

| • |

Lugs must sit in grooves of gear wheel

|

|

| 37. |

Place intermediate ring (2) onto inner synchro ring

|

| 38. |

Place outer synchro ring (1) onto intermediate ring

| • |

Grooves must sit on lugs of inner synchro ring

|

|

| 39. |

Place synchro body assembly (5) onto main shaft

|

| 40. |

Press synchro body assembly onto main shaft with KM-277 (6)

| • |

Lugs in outer synchro ring must align with grooves in synchro

body

|

| • |

Shift fork groove (arrow) points towards ball bearing seat

|

|

| 41. |

Insert new retaining ring (8) in front of 1st/2nd gear synchro

body with circlip pliers (7)

|

|

|

| 42. |

Place outer synchro ring (3) with lugs in grooves of synchro

body (4)

|

| 43. |

Place intermediate ring (2) onto outer synchro ring

|

| 44. |

Place inner synchro ring (1) onto intermediate ring

| • |

Lugs must engage in grooves of outer synchro ring

|

|

| 45. |

Place 1st gear needle bearing (5) onto main shaft

Note: If present.

|

| 46. |

Slide 1st gear gearwheel onto needle bearing

| • |

Grooves must sit on lugs of intermediate ring

|

|

| 47. |

Place axial needle bearing (8) onto 1st gear gearwheel (10)

| • |

Place spacer washer (7) onto needle bearing

|

|

| 48. |

Place new retaining ring (9) with long legs for main shaft at

end shield onto 1st gear gearwheel

| • |

Press ball bearing (6) onto main shaft with KM-334 (11)

|

|

|

|

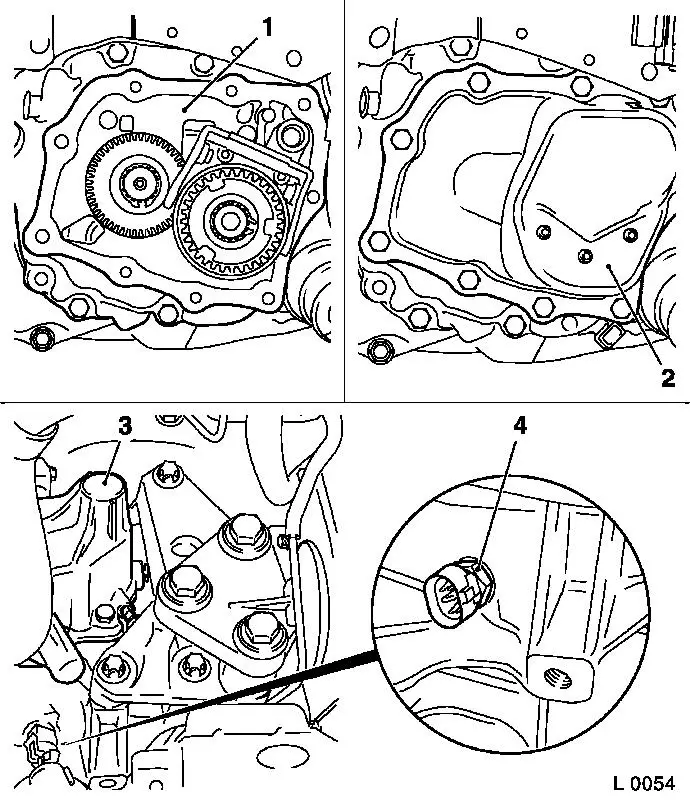

| 49. |

All gears must turn easily

|

| 51. |

Install end shield (1) in transmission

|

| 52. |

Install end shield cover (2)

|

| 53. |

Install reversing lamp switch (4) with new seal ring

|

| 54. |

Install gearshift cover (3)

|

|

|