|

Remove and install manual transmission

(F13/F17/F17 new/F17+)

Remove Remove

| 1. |

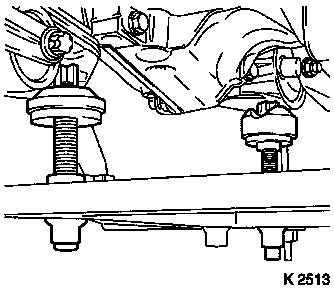

Align drive unit

Note: In order to

ensure that the drive unit is correctly aligned when the left

engine damping block bolts are undone, the drive unit must be

aligned with the front axle body using the KM-6169

|

|

|

| 2. |

Remove crash box

| • |

Z 13 DT / Z 13 DTJ / Z 17 DTH

|

|

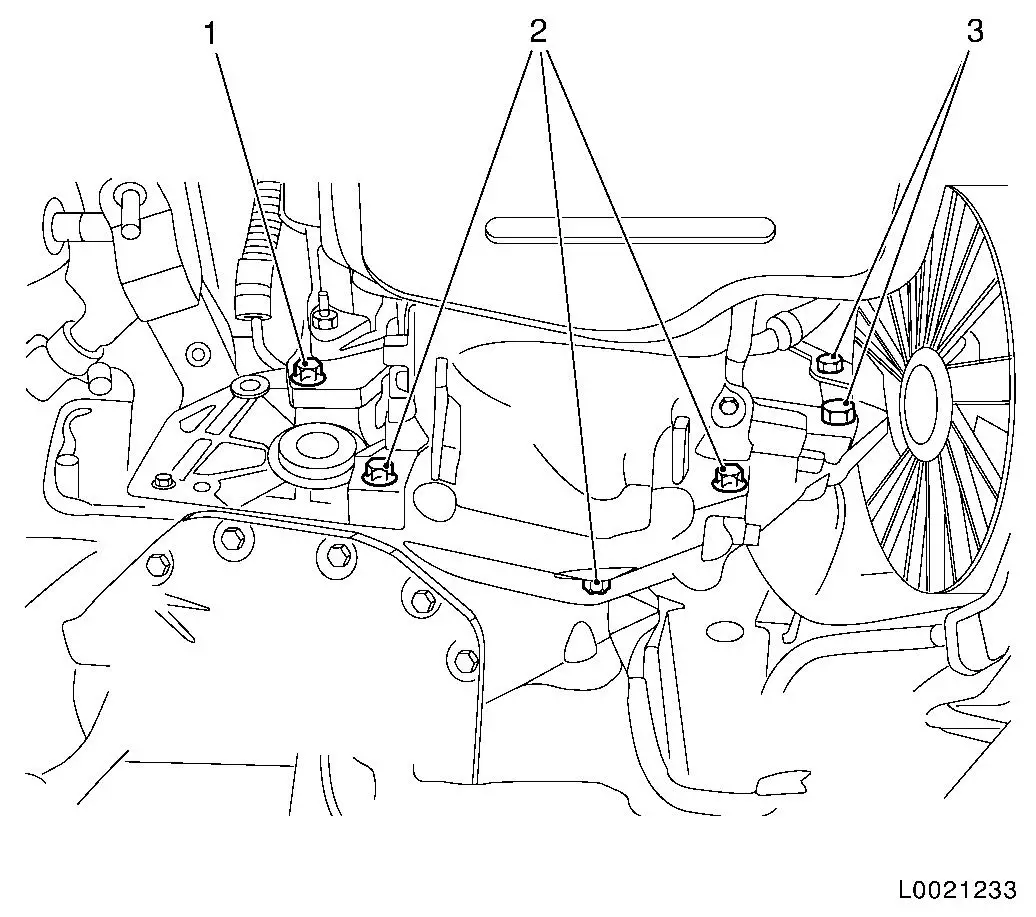

| 3. |

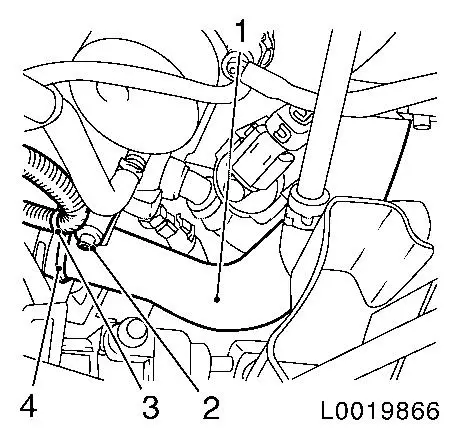

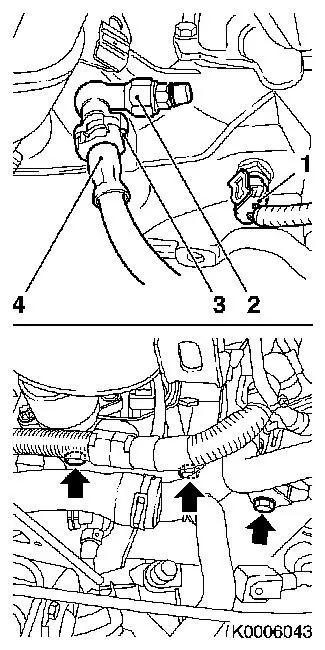

Remove charge air pipe (1)

Note: Only required for

Z 13 DT and Z 13 DTJ.

| • |

Unclip wiring harness (3)

|

|

|

|

| 4. |

Fill brake fluid reservoir to "MAX" mark and seal with MKM-558-10 .

|

| 5. |

Remove upper engine cover

Note: If present.

|

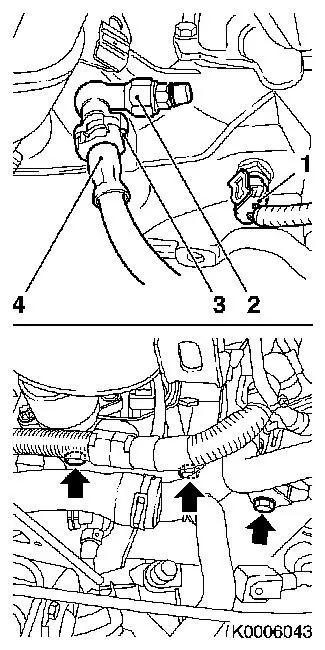

| 6. |

Disconnect pressure line (4) from connector (2) for pressure

line for central release from transmission housing

| • |

Release clamp (3) with screwdriver and remove

|

| • |

Bend clamp together a little and insert back into connector

Note: Collect escaping

brake fluid

|

|

| 7. |

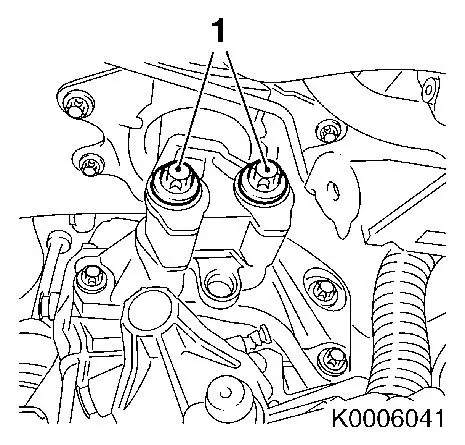

Detach wiring harness plug (1) from reversing lamp switch

|

| 8. |

Disconnect wiring harness plug from coolant temperature

sensor

Release wiring harness plug and disconnect.

Note: Only required for

Z 13 DT and Z 13 DTJ.

|

| 9. |

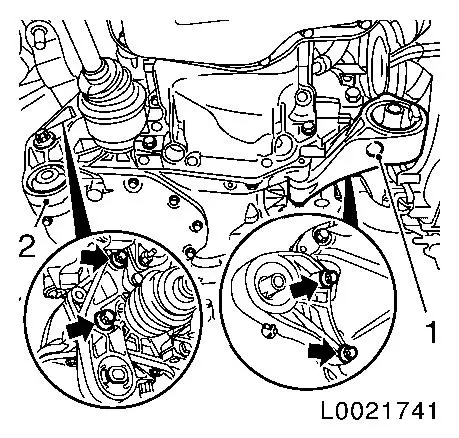

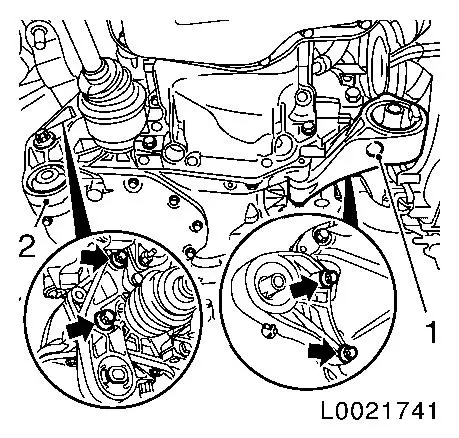

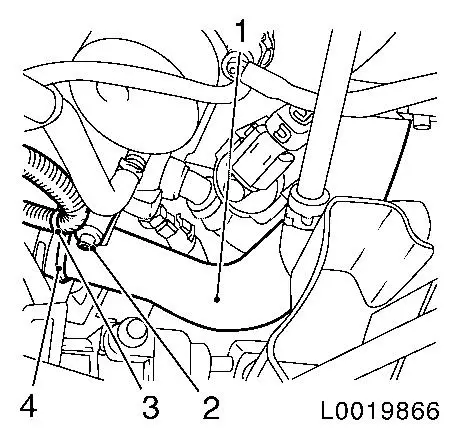

Remove 3 transmission bolts (arrows)

Note: If necessary pull

coolant pipe upwards and secure with cable ties

|

|

|

| 10. |

Remove front axle body

Note: The tool KM-6169 remains on the front axle body and must

not be adjusted.

|

| 11. |

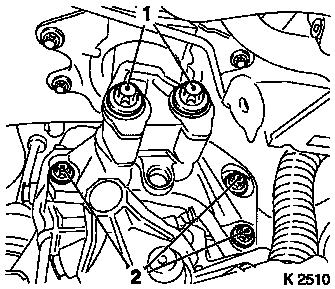

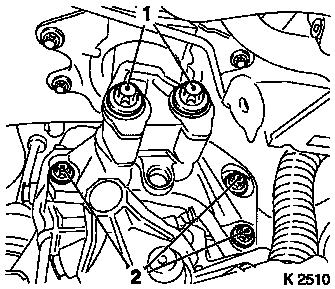

Remove engine damping block retaining bracket

| • |

Remove left engine damping block bolts (1)

|

| • |

Remove 2 bolts (2) for left engine damping block retaining

bracket from transmission

|

|

| 12. |

Lower engine with transmission on MKM-883-1 by approx. 5 cm

Note: Ensure that the

coolant hoses and wiring harnesses are not stretched.

|

| 13. |

Detach shift linkage from shift guide

|

|

|

Important: Fluid escapes. Place

collecting pan underneath and close off apertures with plug.

|

| 14. |

Remove axle shafts from transmission

Note: Axle shafts

remain in wheel hubs.

| • |

Attach axle shafts to vehicle underbody

|

|

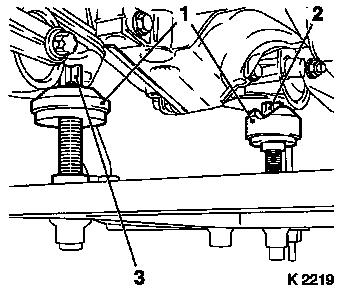

| 15. |

Detach front engine damping block (2) from transmission

Note: If present.

| • |

Unscrew 2x bolt (arrows)

|

|

| 16. |

Detach rear engine damping block bracket (3) from

transmission

| • |

Unscrew 2x bolt (arrows)

|

|

|

|

|

| 17. |

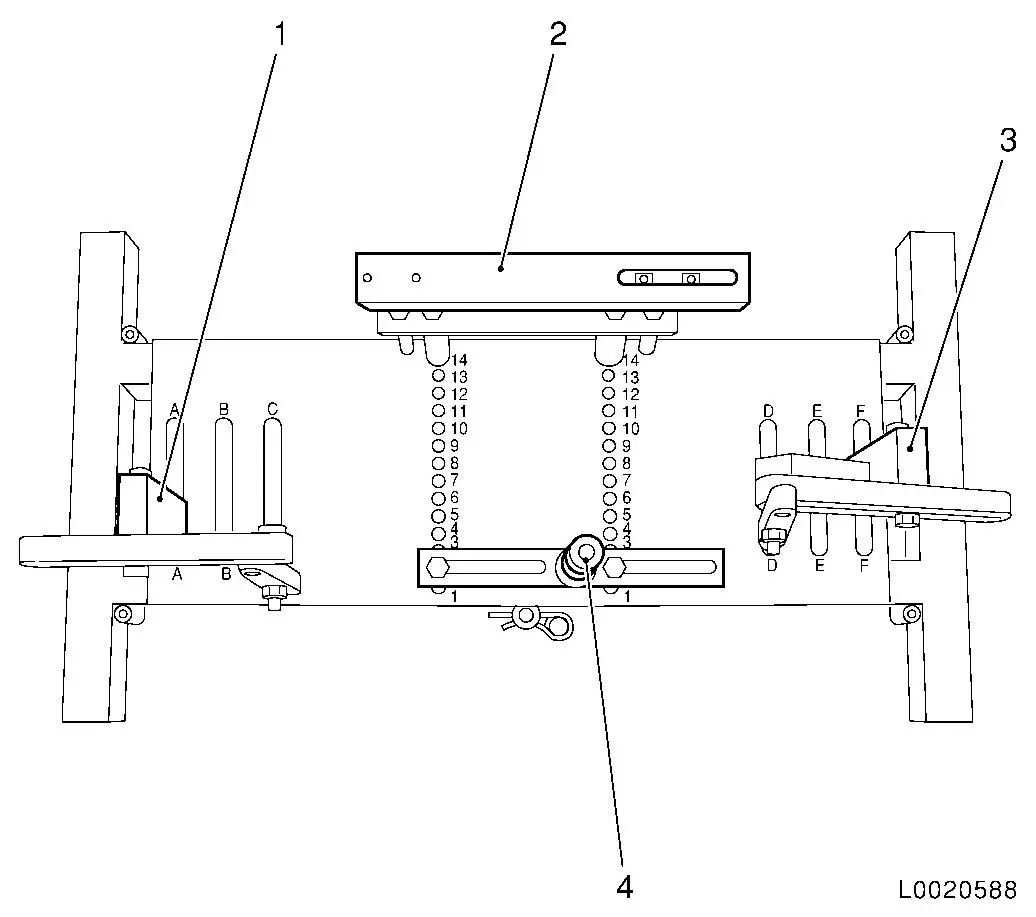

Position transmission holder DT-47648

on KM-904 and preinstall as shown in the

illustration:

|

Component

|

Position on base plate

|

Designation

|

|

DT-47648-2

(4)

|

2

|

Clutch housing support

|

|

DT-47648-3

(2)

|

14

|

Transmission housing support

|

|

DT-47648-5 left

(1)

|

A

|

Support with rear transmission swivel arm

|

|

DT-47648-5 right

(3)

|

F

|

Support with front transmission swivel arm

|

|

|

Important: It is important that

the manufacturer's instructions for transmission holder DT-47648 are followed.

|

| 18. |

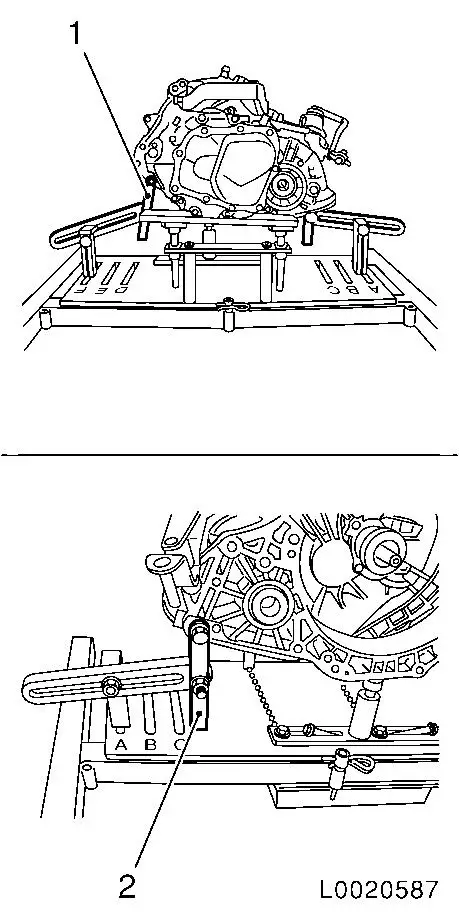

Attach transmission holder DT-47648

to transmission

Note: Before placing in

position, slacken all bolt connections of the swivel arms and

supports as far as the base plate. Adjust the supports using the

spindles until they are as low as possible.

| • |

Position transmission holder DT-47648

and supports under the transmission

|

| • |

Tighten the bolt connections of the supports

|

| • |

Attach swivel arms (1) and (2) to transmission

|

| • |

Tighten bolt connections of swivel arms, starting from the

transmission and going as far as the base plate

Note: Align the swivel

arms so that as little leverage as possible is created.

|

|

|

|

|

| 19. |

Remove transmission

| • |

Unscrew 3x bolts (2), transmission to oil pan

|

| • |

Unscrew 3x bolts (1) and (3), transmission to cylinder

block

Note: Note different

bolt lengths

|

| • |

Push transmission away from engine

|

Important: Do not damage add-on

parts.

|

| • |

Carefully lower the transmission with the hydraulic jack and

extend the hydraulic jack

|

|

|

Important: Do not damage

attaching parts when laying transmission down.

|

| 20. |

Detach transmission from DT-47648

Note: 2nd person

required

| • |

Carefully lay transmission down

|

|

Install

Install

| 21. |

Install transmission with DT-47648

| • |

Raise and align transmission

|

| • |

Place transmission so that it is in even contact with the

engine

Note: Ensure that it is

properly seated

|

|

|

Important: Ensure that no cables

and brackets get trapped between the transmission and engine.

|

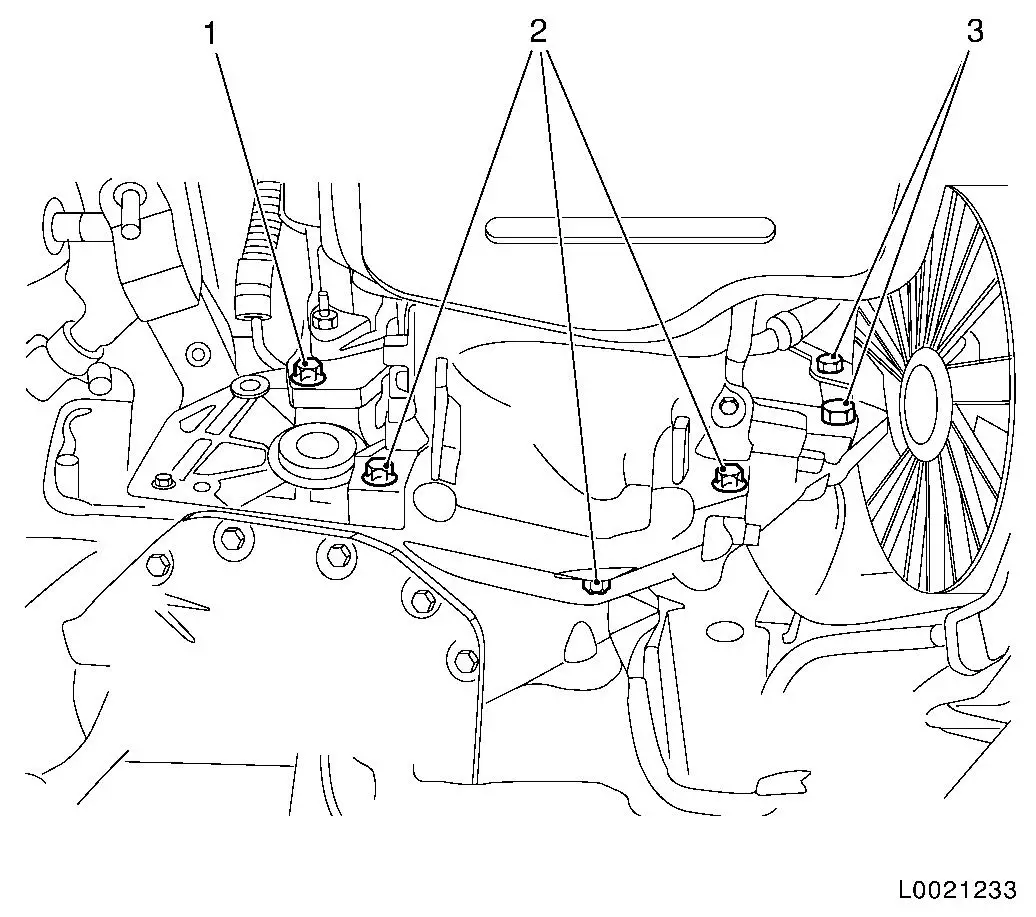

| 22. |

Install transmission

| • |

Insert wiring harness bracket with front bolt

|

| • |

Tighten 3x bolts (1) and (3), transmission to cylinder block

60 Nm

|

| • |

Tighten 3x bolts (2), transmission to oil pan 40 Nm

|

|

|

| 23. |

Detach transmission holder DT-47648

from transmission

| • |

Lower and extend hydraulic jack

|

|

| 24. |

Attach front engine damping block (2) to transmission

|

| 25. |

Attach rear engine damping block bracket (3) to

transmission

| • |

Tighten 2x new bolts 80 Nm + 45°

– 60°

|

|

|

|

| 26. |

Attach new retaining ring to axle shaft

|

| 27. |

Attach axle shafts to transmission

| • |

Detach axle shafts from vehicle underbody

|

|

| 28. |

Attach left engine damping block retaining bracket

| • |

Tighten 2 bolts (2) 60 Nm

|

|

| 29. |

Lift engine with KM-883-1 until

installation position is reached

Note: Ensure that there

is some clearance between the left engine damping block and the

engine damping block bracket.

|

| 30. |

Loosely fit 2 new engine damping block brackets (1) to the

engine damping block retaining bracket

Note: Do not tighten

bolts yet

|

|

|

Important: When installing the

front axle body, ensure that the support bearings (1) of the KM-6169 are correctly seated in the guide pins

of the front engine damping block (2) and the rear engine damping

block bracket (3). If necessary, correct installation position of

engine and transmission using MKM-883-1

.

|

| 31. |

Install front axle body

|

|

|

| 32. |

Tighten 2 engine damping block brackets (1) at engine damping

block retaining bracket 80 Nm + 60°

– 75°

|

| 33. |

Detach and remove KM-883-1

|

|

|

| 34. |

Fasten transmission at the top

| • |

Tighten upper transmission bolts (arrows) 60 Nm

|

| • |

Tighten ground cable 60 Nm

|

| • |

Tighten wiring harness bracket 60

Nm

Note: If present.

|

| • |

Tighten coolant pipe bracket at transmission 60 Nm

Note: If present.

|

|

| 35. |

Connect wiring harness plug for coolant temperature sensor and

lock

Note: Only required for

Z 13 DT and Z 13 DTJ.

|

| 36. |

Attach pressure line (4) to connecting piece (2) for pressure

line for central release at clutch housing

Note: Clamp (3) must

audibly engage.

|

| 37. |

Connect wiring harness plug (1) to reversing lamp switch

|

|

|

| 38. |

Install charge air pipe (1)

Note: Only required for

Z 13 DT and Z 13 DTJ.

| • |

Clip in wiring harness (3)

|

|

|

|

| 39. |

Check transmission fluid level and correct if necessary

|

| 40. |

Slide shift guide onto shift rod

|

| 41. |

Transmission Shift Linkage, Adjust

|

| 42. |

Install lower and upper engine compartment cover

Note: If present.

|

| 43. |

Detach MKM-558-10 from brake fluid

reservoir

|

| 44. |

Install crash box

| • |

Z 13 DT / Z 13 DTJ / Z 17 DTH

|

|

| 45. |

Bleed hydraulic clutch actuation

| • |

Correct brake fluid reservoir to "MAX" mark

|

|

| 46. |

Program volatile memory

|

|