|

All Pistons with Con-Rods, Remove and Install

Remove Remove

| 2. |

Drain engine oil

| • |

Place collecting basin underneath.

|

|

| 3. |

Detach wiring harness plug from dynamic oil level check

sensor

|

| 6. |

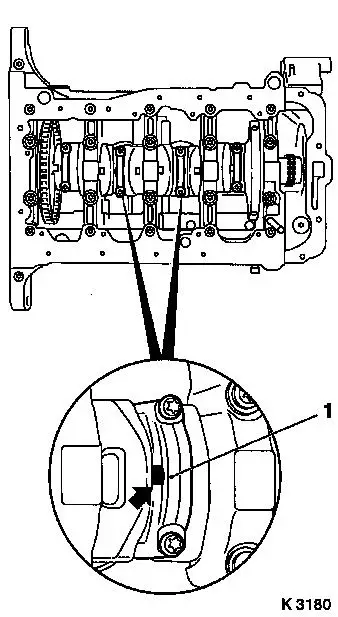

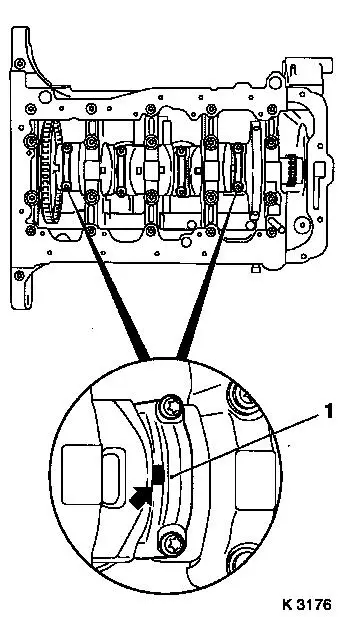

Detach con-rod bearing caps (1) from cylinder 2 and 3

Note: The mating

surfaces of the con-rods and con-rod bearing caps form an

individual fit and should never be swapped over or damaged. To

avoid damage, do not put the con-rods and con-rod bearing caps down

on the mating surfaces.

| • |

Mark order of con-rod bearing caps

|

| • |

Take out 4x con-rod bearing caps

Note: Note installation

position, bead (arrow) on the con-rod bearing cap points towards

the transmission side.

|

| • |

Push piston with con-rod upwards

|

|

|

|

| 7. |

Lower vehicle by its full height

|

| 8. |

Take 2x piston with con-rod out of cylinder block

|

| 9. |

Turn crankshaft

| • |

Pull timing chain upwards

|

|

| 10. |

Raise vehicle by its full height

|

| 11. |

Detach con-rod bearing caps (1) from cylinder 1 and 4

Note: The mating

surfaces of the con-rods and con-rod bearing caps form an

individual fit and should never be swapped over or damaged. To

avoid damage, do not put the con-rods and con-rod bearing caps down

on the mating surfaces.

| • |

Mark order of con-rod bearing caps

|

| • |

Take out 4x con-rod bearing caps

Note: Note installation

position, bead (arrow) on the con-rod bearing cap points towards

the transmission side.

|

| • |

Push piston with con-rod upwards

|

|

|

|

| 12. |

Lower vehicle by its full height

|

| 13. |

Take 2x piston with con-rod out of cylinder block

|

Install

Install

| 14. |

Clean and check all the components, replace if necessary

Note: Pistons may only

be replaced in conjunction with con-rod and piston pin.

|

| 15. |

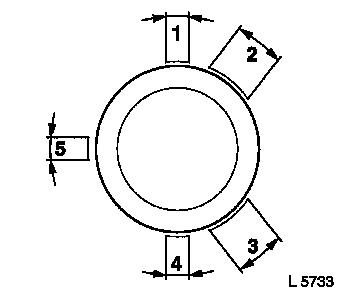

Set piston ring gap

| • |

First piston ring (right-hand ring) in position (1)

|

| • |

Second piston ring (minute ring) in position (4)

|

| • |

Interim ring of oil scraper ring in position (5), steel band

rings of oil scraper ring in position (2) and/or (3)

|

|

|

|

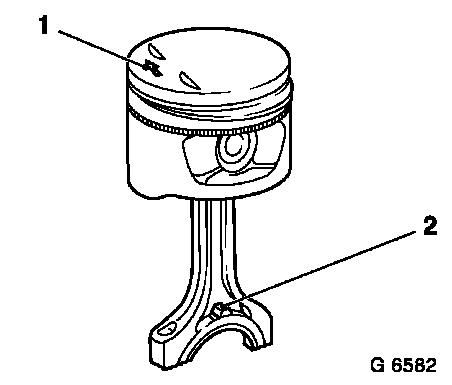

| 16. |

Install piston of cylinder 1 and 4

Note: Arrow (1) on the

piston head points to engine timing side – bead (2) on the

con-rod points to transmission side.

| • |

Coat pistons and cylinder bores with engine oil

|

| • |

Push piston rings together with piston tightening strap

|

| • |

Carefully push piston into cylinder bore with hammer shaft

until con-rod sits on the con-rod bearing journal of the

crankshaft

|

|

|

|

| 17. |

Raise vehicle by its full height

|

| 18. |

Install con-rod bearing cap

Note: Bead on con-rod

bearing cover points towards gearbox side.

| • |

Wet con-rod bearing journal with engine oil

|

Important: Only use bolts of size

M6.5.

|

| • |

Tighten bolt

| – |

Tightening torque 13 Nm + 60° +

15°

|

|

|

| 19. |

Lower vehicle by its full height

|

| 20. |

Turn crankshaft

| • |

Pull timing chain upwards

|

|

| 21. |

Install piston of cylinder 2 and 3

Note: Arrow on the

piston head points to engine timing side. Bead on the con-rod

points to transmission side.

| • |

Coat pistons and cylinder bores with engine oil

|

| • |

Push piston rings together with piston tightening strap

|

| • |

Carefully push piston into cylinder bore with hammer shaft

until con-rod sits on the con-rod bearing journal of the

crankshaft

|

|

| 22. |

Raise vehicle by its full height

|

| 23. |

Install con-rod bearing cap

Note: Bead on con-rod

bearing cover points towards gearbox side.

| • |

Wet con-rod bearing journal with engine oil

|

Important: Only use bolts of size

M6.5.

|

| • |

Tighten bolt

| – |

Tightening torque 13 Nm + 60° +

15°

|

|

|

| 24. |

Screw 2x centring pin into engine block using EN-49980

Note: Screw centring

pin diagonally into engine block, hand-tight.

|

| 25. |

Install oil pan

| • |

Complete assembly work within 10 minutes

|

| • |

Unscrew 2x centring pin from engine block using EN-49980

|

| • |

Tighten 3x bolt on transmission

| – |

Tightening torque 40 Nm .

|

|

| • |

Tighten 16x bolt from cylinder block

| – |

Tightening torque 10 Nm .

|

|

|

| 26. |

Screw oil drain bolt into oil pan

| • |

Tighten oil drain bolt

| – |

Tightening torque 14 Nm .

|

|

|

| 27. |

Detach wiring harness plug from dynamic oil level check

sensor

|

| 28. |

Install cylinder head

|

| 29. |

Charge with specified volume of engine oil.

| • |

Start engine and allow to run until oil pressure control

indicator goes off

|

| • |

Check engine oil level, correct if necessary

|

|

|