|

Piston Rings, Replace

Remove Remove

| 2. |

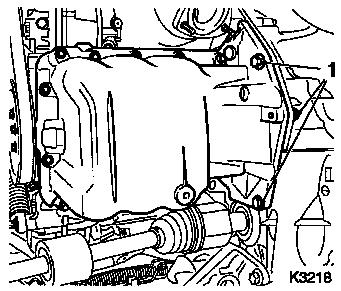

Raise vehicle by its full height

|

| 3. |

Drain engine oil

| • |

Place collecting basin underneath.

|

|

| 4. |

Remove oil pan

| • |

Cylinder block base plate

|

|

|

|

| 6. |

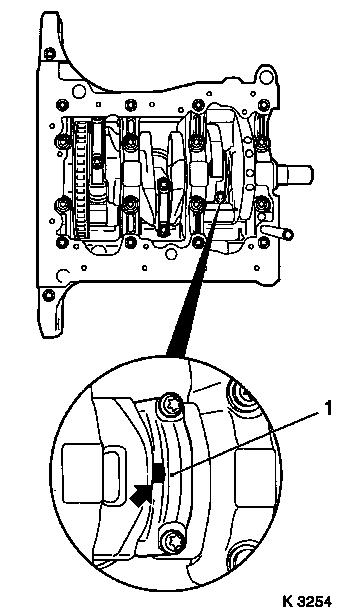

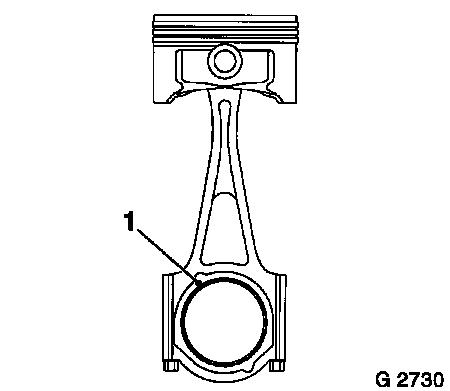

Remove con-rod bearing caps (1) of cylinder 1

Note: The mating

surfaces of the con-rods and con-rod bearing caps form an

individual fit and should never be swapped over or damaged. To

avoid damage, do not put the con-rods and con-rod bearing caps down

on the mating surfaces.

| • |

Mark order of con-rod bearing caps

|

| • |

Remove con-rod bearing cap

Note: Note installation

position, bead (arrow) on the con-rod bearing cap points towards

the transmission side

|

| • |

Push piston with con-rod upwards

|

|

|

|

| 7. |

Lower vehicle by its full height

|

| 8. |

Remove piston with con-rod from cylinder block

|

| 9. |

Turn crankshaft

| • |

Pull timing chain upwards

|

|

| 10. |

Raise vehicle by its full height

|

| 11. |

Remove con-rod bearing cap of cylinder 2

Note: The mating

surfaces of the con-rods and con-rod bearing caps form an

individual fit and should never be swapped over or damaged. To

avoid damage, do not put the con-rods and con-rod bearing caps down

on the mating surfaces.

| • |

Mark order of con-rod bearing caps

|

| • |

Remove con-rod bearing cap

Note: Note installation

position, bead (arrow) on the con-rod bearing cap points towards

the transmission side

|

| • |

Push piston with con-rod upwards

|

|

| 12. |

Lower vehicle by its full height

|

| 13. |

Remove piston with con-rod from cylinder block

|

| 14. |

Turn crankshaft

| • |

Pull timing chain upwards

|

|

| 15. |

Raise vehicle by its full height

|

| 16. |

Remove con-rod bearing cap of cylinder 3

Note: The mating

surfaces of the con-rods and con-rod bearing caps form an

individual fit and should never be swapped over or damaged. To

avoid damage, do not put the con-rods and con-rod bearing caps down

on the mating surfaces.

| • |

Mark order of con-rod bearing caps

|

| • |

Remove con-rod bearing cap

Note: Note installation

position, bead (arrow) on the con-rod bearing cap points towards

the transmission side

|

| • |

Push piston with con-rod upwards

|

|

| 17. |

Lower vehicle by its full height

|

| 18. |

Remove piston with con-rod from cylinder block

|

Install

Install

| 19. |

Clean and check all the components, replace if necessary

Note: Pistons may only

be replaced in conjunction with con-rod and piston pin

|

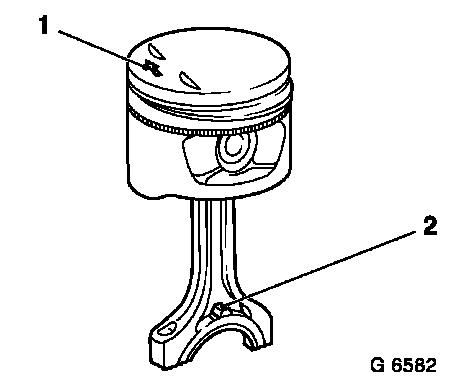

| 20. |

Insert con-rod bearing shells into con-rods and con-rod bearing

caps

|

| 21. |

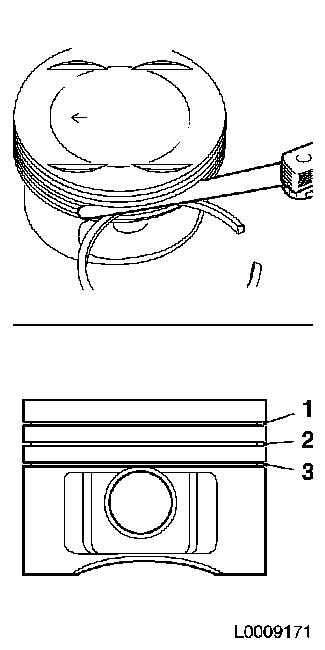

Check piston ring vertical play with feeler gauge in piston

ring groove.

| • |

Rectangular compression ring (1)

|

| • |

Tapered compression ring (2)

|

|

|

|

| 22. |

Install piston rings

| • |

Insert piston rings in ring groove using piston ring pliers

| – |

Marking "TOP" at the top

|

|

|

| 23. |

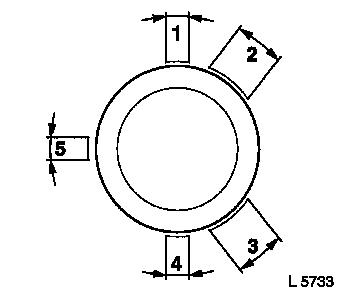

Set piston ring gap

| • |

First piston ring (right-hand ring) in position (1)

|

| • |

Second piston ring (minute ring) in position (4)

|

| • |

Interim ring of oil scraper ring in position (5), steel band

rings of oil scraper ring in position (2) and/or (3)

|

|

|

|

| 24. |

The bead (1) on the con-rod points towards the transmission

side

|

|

|

| 25. |

Install piston of cylinder 1

Note: Arrow (1) on the

piston head points to engine timing side – bead (2) on the

con-rod points to transmission side

| • |

Coat pistons and cylinder bores with engine oil

|

| • |

Push piston rings together with piston tightening strap

|

| • |

Push piston into cylinder bore with hammer shaft until con-rod

sits on the con-rod bearing journal of the crankshaft

|

|

|

|

| 26. |

Raise vehicle by its full height

|

| 27. |

Install con-rod bearing cap

Note: Bead on the

con-rod bearing cap points to transmission side

| • |

Wet con-rod bearing journal with engine oil

|

Important: Only use screws of

size M6.5

|

| • |

Tighten 2x bolt 13 Nm + 60° +

15°

|

|

| 28. |

Lower vehicle by its full height

|

| 29. |

Turn crankshaft

| • |

Pull timing chain upwards

|

|

| 30. |

Install piston of cylinder 2

Note: Arrow (1) on the

piston head points to engine timing side – bead (2) on the

con-rod points to transmission side

| • |

Coat pistons and cylinder bores with engine oil

|

| • |

Push piston rings together with piston tightening strap

|

| • |

Push piston into cylinder bore with hammer shaft until con-rod

sits on the con-rod bearing journal of the crankshaft

|

|

| 31. |

Raise vehicle by its full height

|

| 32. |

Install con-rod bearing cap

Note: Bead on the

con-rod bearing cap points to transmission side

| • |

Wet con-rod bearing journal with engine oil

|

Important: Only use screws of

size M6.5

|

| • |

Tighten 2x bolt 13 Nm + 60° +

15°

|

|

| 33. |

Install piston of cylinder 3

Note: Arrow (1) on the

piston head points to engine timing side – bead (2) on the

con-rod points to transmission side

| • |

Coat pistons and cylinder bores with engine oil

|

| • |

Push piston rings together with piston tightening strap

|

| • |

Push piston into cylinder bore with hammer shaft until con-rod

sits on the con-rod bearing journal of the crankshaft

|

|

| 34. |

Raise vehicle by its full height

|

| 35. |

Install con-rod bearing cap

Note: Bead on the

con-rod bearing cap points to transmission side

| • |

Wet con-rod bearing journal with engine oil

|

Important: Only use screws of

size M6.5

|

| • |

Tighten 2x bolt 13 Nm + 60° +

15°

|

|

| 36. |

Install oil pan with new gasket

Note: Comply with the

following tightening sequence

| • |

Tighten 14 bolts on cylinder block base plate 10 Nm

|

| • |

Tighten 3x bolt on transmission 40

Nm

|

|

| 37. |

Attach oil drain bolt to oil pan

| • |

Tighten drain bolt 10 Nm

|

|

| 38. |

Lock crankshaft

| • |

Pull timing chain upwards

|

| • |

Turn crankshaft evenly until KM-952

engages

|

|

| 39. |

Lower vehicle by its full height

|

| 40. |

Install cylinder head

|

|