|

Replace all valve stem seals (cylinder head

installed)

Remove Remove

| 2. |

Remove air cleaner housing

|

| 3. |

Remove ignition module

|

| 4. |

Remove cylinder head cover

|

| 6. |

Remove gasket remnants and clean sealing surfaces

|

| 7. |

Remove intake camshafts and exhaust camshaft

|

| 8. |

Remove hydraulic valve lifter

Note: Note removal

sequence.

|

| 9. |

Remove lower engine compartment cover / splash guard

|

| 10. |

Adjust TDC of combustion stroke of cylinder 1

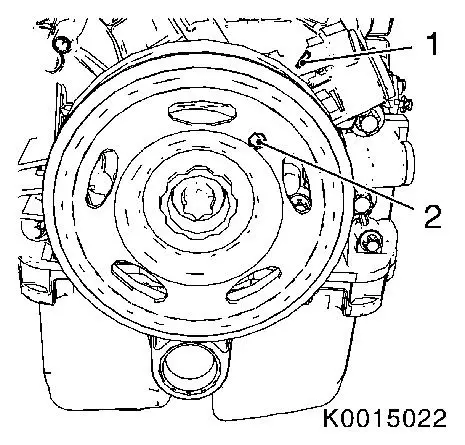

| • |

Marking on the ribbed V-belt pulley marker bore (2) must align

with the cast projection (1) on the timing case

|

|

|

|

| 11. |

Make alignment mark

| • |

On crankshaft belt pulley

Note: 180° offset

to marking TDC of combustion stroke cylinder 1.

|

|

| 12. |

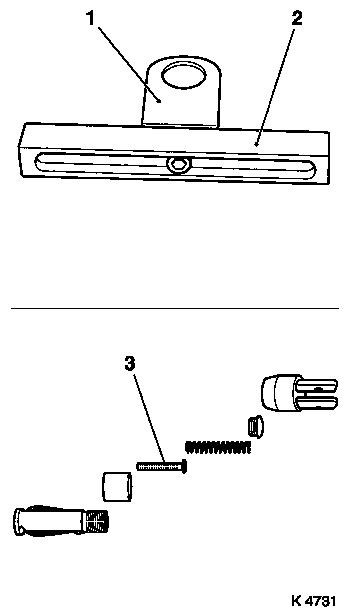

Prepare automatic valve spring lever MKM-6086

| • |

Adjust MKM-6086-6 supports (2)

| – |

Adjust support heads (1) so that they are centred in respect of

the support feet (2) and tighten

|

|

| • |

Complete lever arm MKM-6086-7

| – |

with joint MKM-6086-8 and dismantling

head MKM-6086-10

|

|

|

| 13. |

Complete assembly set MKM-6086-200

| • |

Insert thrust piece MKM-6086-200-11

(3)

Note: Follow

manufacturer's instructions

|

|

|

|

| 14. |

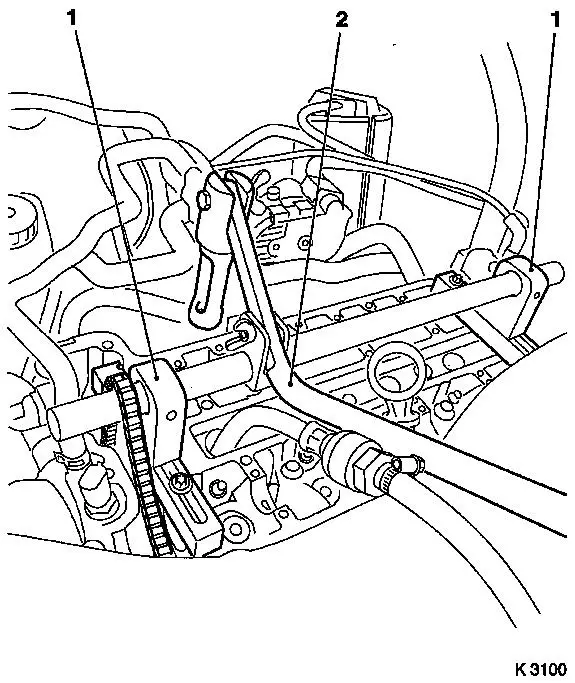

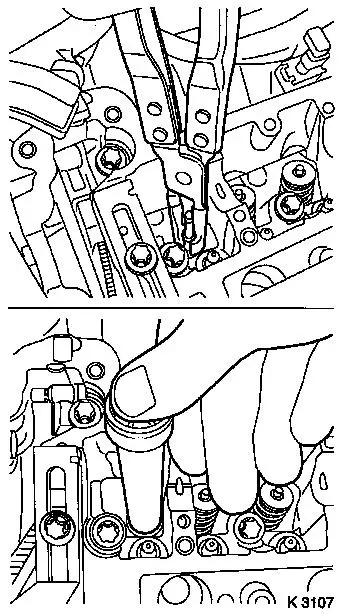

Attach automatic valve spring lever MKM-6086

| • |

Attach 2 supports MKM-6086-6 (1)

| – |

Push assembly shaft in the supports

Note: Align assembly

shaft centrally via spark plug bore.

|

|

| • |

Install lever arm MKM-6086-7 (2)

Note: Removal head must

point towards the intake side.

|

| • |

Secure installation shaft

|

|

|

|

| 15. |

Install compressed air adapter

| • |

Screw into spark plug thread of cylinder 1

|

| • |

Apply compressed air to cylinder 1

|

|

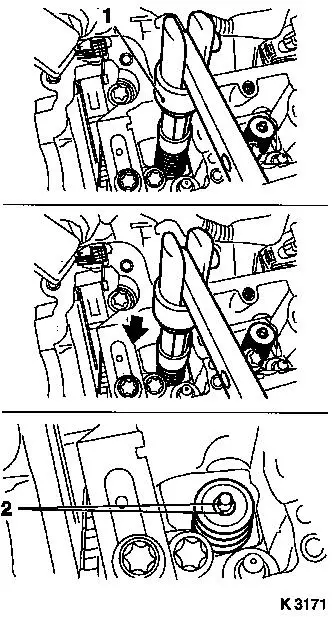

| 16. |

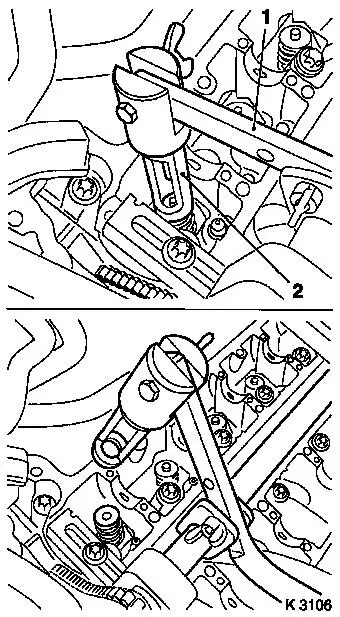

Remove 2 cylinder no.1 intake valve springs

| • |

Press valve spring carefully downwards with lever arm (1)

Note: Removal head (2)

must be positioned vertically over the valve stem.

|

Important: Note allocation.

|

| • |

Take out valve cotters, valve discs, valve springs

Note: Do not use any

magnetic tools.

|

|

|

|

| 17. |

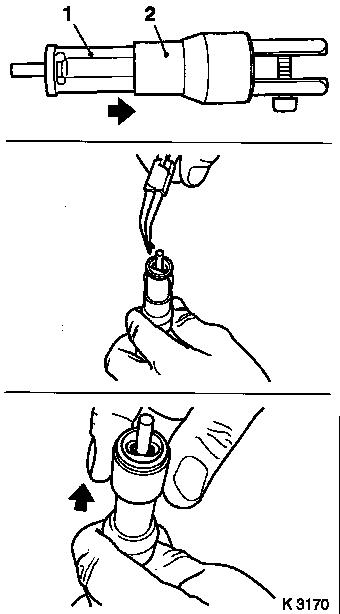

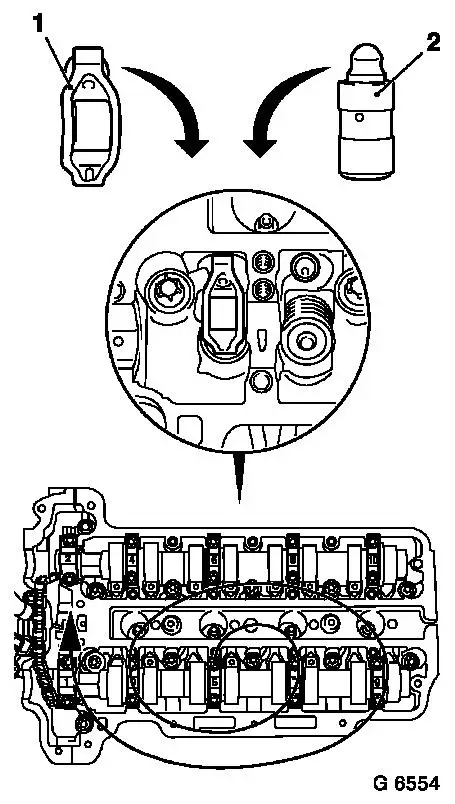

Replace 2x valve stem seals

| • |

Place new valve stem seal on to valve stem

|

| • |

Drive in as far as the stop with KM-958

|

|

|

|

| 18. |

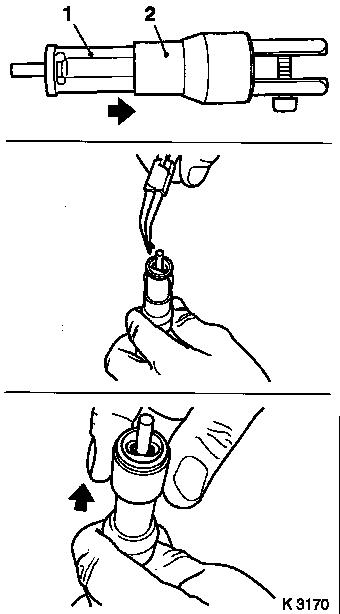

Install intake valve springs, cylinder 1

| • |

Insert valve springs and valve heads

|

| • |

Insert valve cotters into assembly head (1)

| – |

Slide plastic clamping sleeve (2) in direction of lever arm

mount

|

Important: Insert split cotters

with the narrow part facing the valve.

|

| – |

Insert valve cotters

|

| – |

Push plastic clamping sleeve in the direction of the valve

(arrow)

|

|

|

|

|

| 19. |

Install valve cotters

| • |

Attach assembly head (1) to lever arm

|

Important: Assembly head must

stand vertically above valve stem. Valve cotters (2) must engage

audibly.

Important: Do not

make a 2nd attempt without checking that both valve cotters are

seated in the assembly head. Check seat of valve cotters. Ensure

compressed air is being applied.

|

| • |

Press valve spring carefully downwards with lever arm

(arrow)

|

|

|

|

| 20. |

Transfer lever arm

| • |

Install lever arm

Note: Removal head must

point towards the exhaust side.

|

|

| 21. |

Remove 2 cylinder No.1 exhaust valve springs

| • |

Press valve spring carefully downwards with lever arm

Note: Removal head must

be vertical above the valve stem.

|

Important: Note allocation.

|

| • |

Take out valve cotters, valve discs, valve springs

Note: Do not use any

magnetic tools.

|

|

| 22. |

Replace 2x valve stem seals

| • |

Place new valve stem seal on to valve stem

|

| • |

Drive in as far as the stop with KM-958

|

|

| 23. |

Install 2 exhaust valve springs, cylinder 1

| • |

Insert valve springs and valve heads

|

| • |

Insert valve cotters into assembly head (1)

| – |

Slide plastic clamping sleeve (2) in direction of lever arm

mount

|

Important: Insert split cotters

with the narrow part facing the valve.

|

| – |

Insert valve cotters

|

| – |

Push plastic clamping sleeve in the direction of the valve

(arrow)

|

|

|

|

|

| 24. |

Install valve cotters

| • |

Attach assembly head to lever arm

|

Important: Assembly head must

stand vertically above valve stem. Valve cotters must engage

audibly.

Important: Do not

make a 2nd attempt without checking that both valve cotters are

seated in the assembly head. Check seat of valve cotters. Ensure

compressed air is being applied.

|

| • |

Press valve spring carefully downwards with lever arm

|

|

| 25. |

Transfer compressed air adapter

| • |

Interrupt compressed air feed

|

| • |

Unscrew from spark plug thread of cylinder 1

|

| • |

Screw into spark plug thread of cylinder 4

|

| • |

Apply compressed air to cylinder 4

|

|

| 27. |

Replace 4 valve stem seals, cylinder 4

|

| 28. |

Interrupt compressed air feed

|

| 29. |

Remove crankshaft lock KM-952

|

| 30. |

Adjust TDC of combustion stroke of cylinder 3

| • |

Pull timing chain upwards

|

| • |

Turn crankshaft evenly (180°)

Note: Marking made as

aid on crankshaft belt pulley must align with cast projection on

timing case.

|

|

| 31. |

Lock crankshaft with KM-952

|

| 32. |

Transfer compressed air adapter

| • |

Interrupt compressed air feed

|

| • |

Unscrew from spark plug thread of cylinder 4

|

| • |

Screw into spark plug thread of cylinder 2

|

| • |

Apply compressed air to cylinder 2

|

|

| 33. |

Replace 4 valve stem seals, cylinder 2

|

| 34. |

Transfer compressed air adapter

| • |

Interrupt compressed air feed

|

| • |

Unscrew from spark plug thread of cylinder 2

|

| • |

Screw into spark plug thread of cylinder 3

|

| • |

Apply compressed air to cylinder 3

|

|

| 35. |

Replace 4 valve stem seals, cylinder 3

|

| 36. |

Interrupt compressed air feed

|

| 37. |

Detach automatic valve spring lever

|

| 38. |

Remove compressed air adapter

|

| 39. |

Lock crankshaft

| • |

Pull timing chain upwards

|

| • |

Turn crankshaft evenly until KM-952

engages

|

|

Install

Install

| 40. |

Visually check components

| • |

Camshafts, camshaft bearing caps, cylinder head, roller cam

followers, hydraulic valve lifters

|

|

| 41. |

Check camshaft and camshaft bearing for wear

Note: If the camshaft

bearings are faulty, the cylinder head must be replaced. When

replacing the camshaft, the roller cam followers (1) and hydraulic

valve lifters (2) must be replaced.

|

|

|

| 42. |

Clean hydraulic valve lifters and coat with MoS2 sliding

paste

|

| 43. |

Insert hydraulic valve lifters in accordance with marked

allocation

|

| 44. |

Clean roller cam followers and coat with MoS2 sliding paste

|

| 45. |

Insert roller cam followers in accordance with marked

allocation

|

| 46. |

Install intake camshaft and exhaust camshaft

|

| 47. |

Clean phase sensor disk and camshaft sprocket

Note: The following

steps are to be performed to avoid rotating the phase sensor disc

when tightening the camshaft sprocket.

| • |

Clean the contact surface of the phase sensor disk to the

camshaft sprocket

|

| • |

Clean the contact surface of the camshaft sprocket to the phase

sensor disk

|

| • |

Lightly coat the bolt collar of the new bolt with engine

oil

|

|

| 48. |

Attach camshaft sprockets to camshafts

|

| 50. |

Attach sliding rail to cylinder head

|

| 51. |

Timing, Check

| • |

Turn crankshaft through 720°

| – |

Insert locking tool KM-952

|

|

| • |

Insert locking tool KM-953-A into

camshaft

|

| • |

Attach locating tool EN-49977-100 to

phase sensor discs

Note: If EN-49977-100 cannot be inserted, the operation

"timing, adjust" must be repeated

|

|

| 52. |

Detach locating tool EN-49977-100 and

locking tool KM-953-A

|

| 53. |

Remove locking tool KM-952

|

| 54. |

Tighten closure bolt crankshaft bearing bridge 50 Nm

|

| 55. |

Attach cylinder head cover

|

| 56. |

Install 4x spark plug

|

| 57. |

Install ignition module

|

| 58. |

Install air cleaner housing

|

|