|

Crankshaft, Remove and Install

Remove Remove

Remove engine – see operation "Engine, Remove and

Install".

Detach transmission from engine – see operation "Manual

Transmission from Engine, Detach and Reattach" or "Automatic

Transmission with Torque Converter from Engine, Detach and

Reattach".

Attach engine bracket to cylinder block. Mount engine with

Adapters KM-412-13 on Assembly Stands KM-412.

Remove oil pump – see operation "Oil Pump, Remove and

Install".

Remove drive disc or flywheel – see operation "Drive Disc,

Remove and Install" or "Flywheel, Remove and Install".

Remove crankshaft bearing bridge – see operation

"Crankshaft Bearing Bridge, Remove and Install".

Remove Remove

|

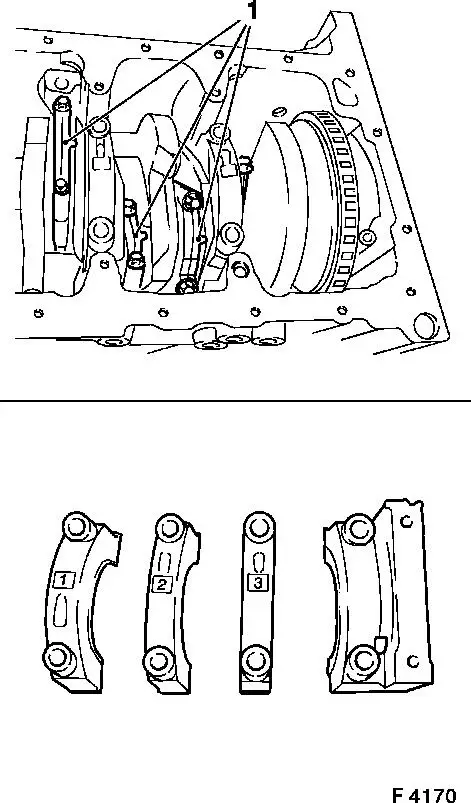

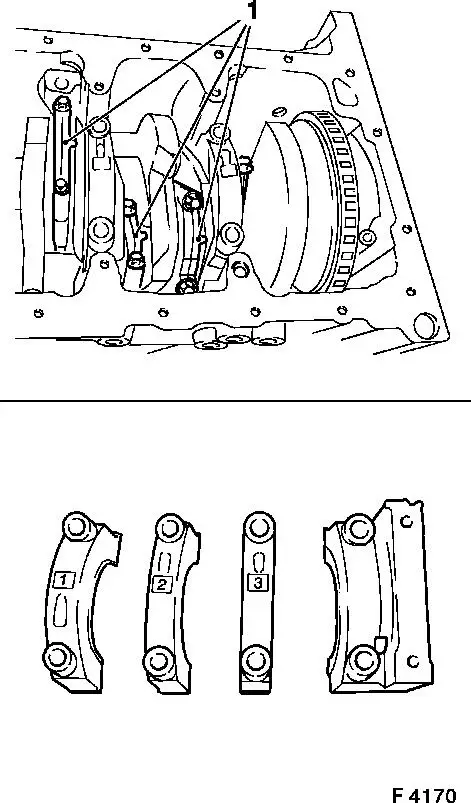

Mark order of con-rod bearing caps – bead (1) of con-rod

bearing caps points to transmission side. Remove con-rod bearing

cap from con-rod. The mating surfaces of the cod-rods and the

con-rod bearing caps form an individual fit and as a result must

not be damaged or replaced under any circumstances. To avoid

damage, do not lay con-rods and con-rod bearing caps on mating

surfaces.

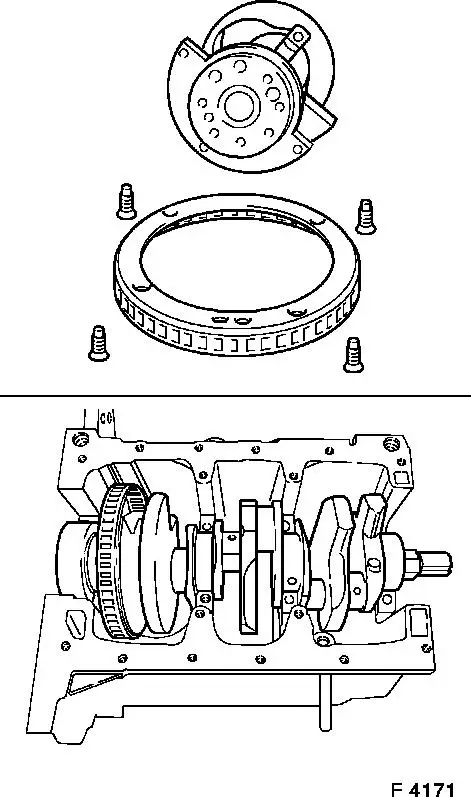

Remove crankshaft bearing cover – mark installation

position. Remove crankshaft from cylinder block.

Caution

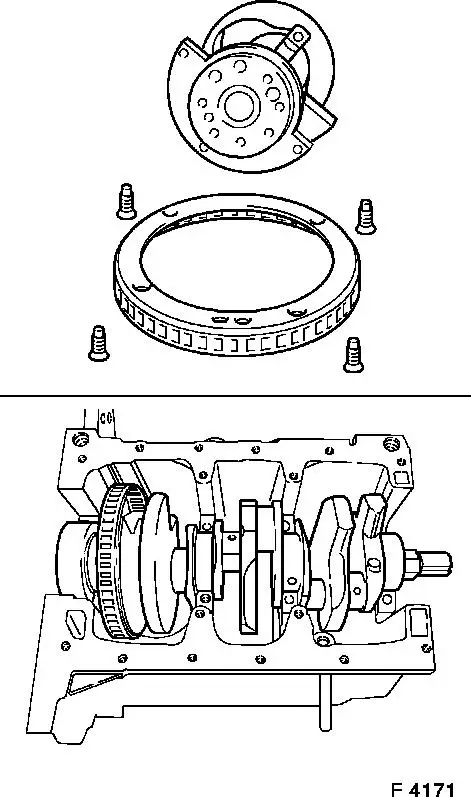

Note crankshaft pulse pickup sensor disc when removing and

laying aside the crankshaft. Deformation of the sensor disc

negatively affects the engine.

|

|

Remove Remove

|

When replacing crankshaft – remove crankshaft pulse pickup

sensor disc.

Clean Clean

Clean all parts. Check crankshaft – see operation

"Crankshaft, Check".

Install

Install

When replacing crankshaft – attach crankshaft pulse

pick-up sensor disc with new bolts to crankshaft – tightening

torque 15 Nm / 11 lbf. ft.

Coat bearing shells with engine oil. Insert new bearing shells

in cylinder block and bearing cap. Insert crankshaft in cylinder

block.

The seating of the crankshaft can be corrected by light blows on

the crank webs with a rubber hammer.

|

|

|

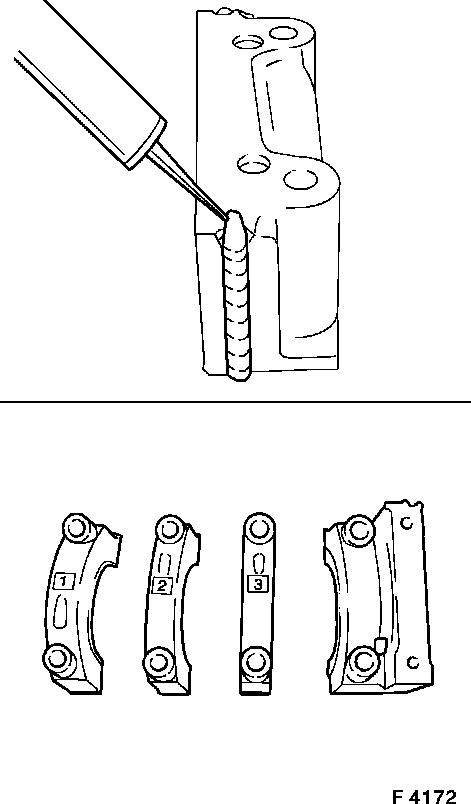

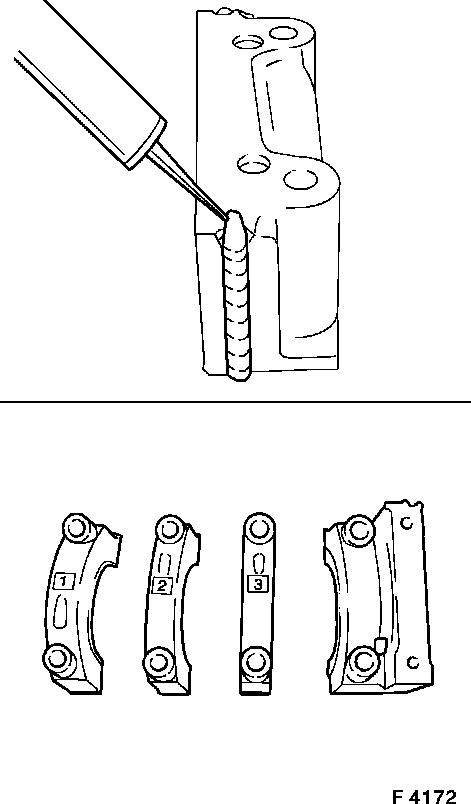

Apply bead of adhesive sealing compound (black) to grooves of

the rear crankshaft.

Install crankshaft and con-rod bearing caps.

Caution

Note marks and installation position.

Torque/angle method

Crankshaft bearing cap to cylinder block – 50 Nm + 60°

+ 15° 1)

2) . Con-rod bearing cap to con-rod – 35 Nm + 45° +

15° 1)

.

|

|

|

Install

Install

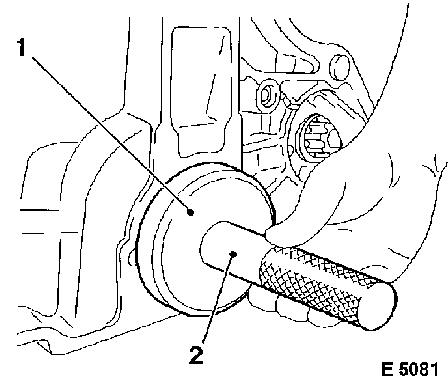

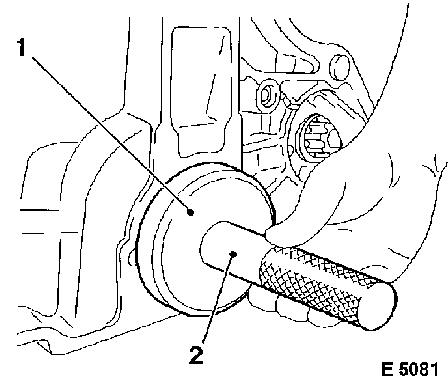

Lightly coat sealing lip of new seal ring with silicon grease

(white) and press over Protective Ring KM-635-1.

Drive seal ring into cylinder block with KM-635-2 (1) and KM-535

(2).

Clean Clean

Clean contact surfaces of crankshaft and flywheel or drive

disc.

|

|

Install

Install

Install crankshaft bearing bridge – see operation

"Crankshaft Bearing Bridge, Remove and Install".

Install drive disc or flywheel – see operation "Drive

Disc, Remove and Install" or "Flywheel, Remove and Install".

Install oil pump – see operation "Oil Pump, Remove and

Install".

Attach transmission to engine – see operation "Manual

Transmission from Engine, Detach and Reattach" or "Automatic

Transmission with Torque Converter from Engine, Detach and

Reattach".

Detach engine from Assembly Stands KM-412 and Adapter KM-412-13

from engine. Attach engine damping block bracket to cylinder block

– tightening torque 40 Nm / 30 lbf. ft. Install engine

– see operation "Engine, Remove and Install".

1 ) Use new bolts.

2 ) After assembling the bearing cap, press in

adhesive sealing compound (black) from above again until adhesive

sealing compound (black) escapes from the joints.

|