|

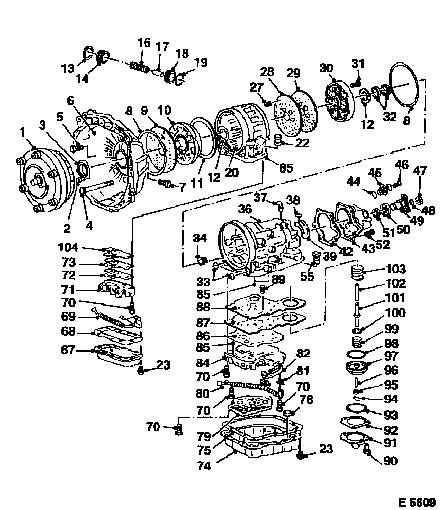

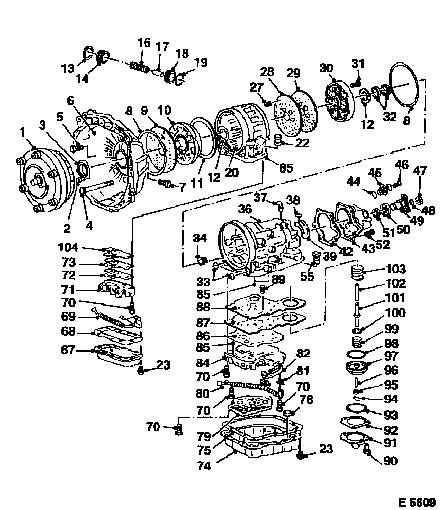

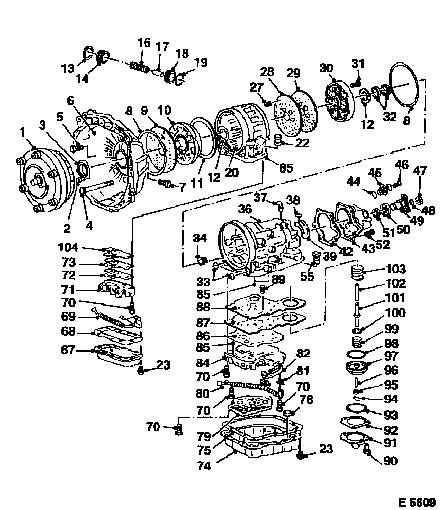

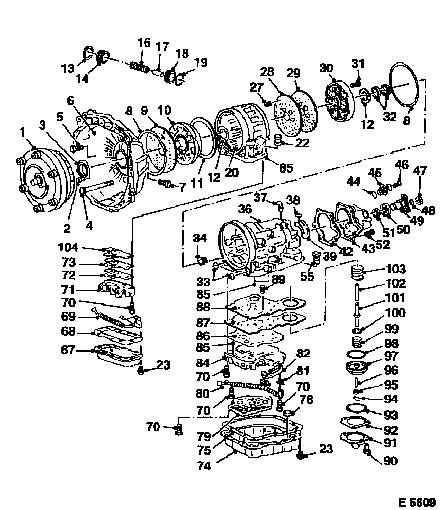

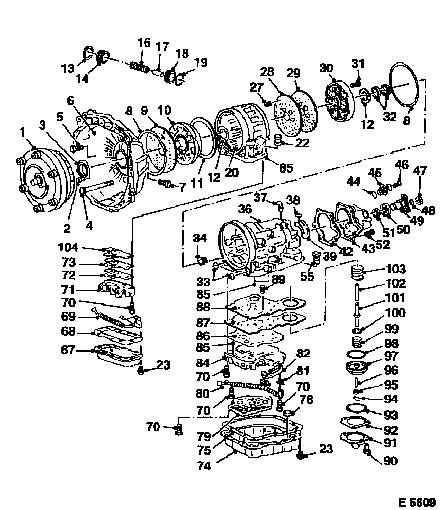

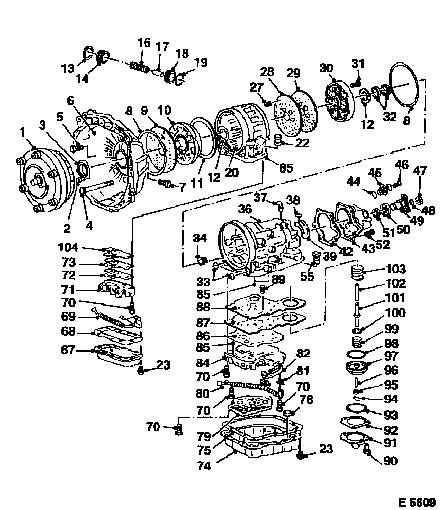

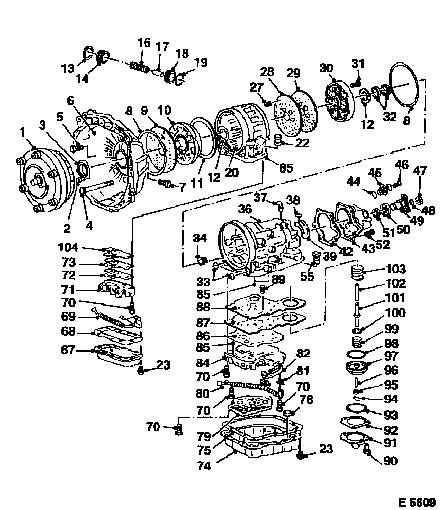

Removing and installing assemblies

Illustrations

|

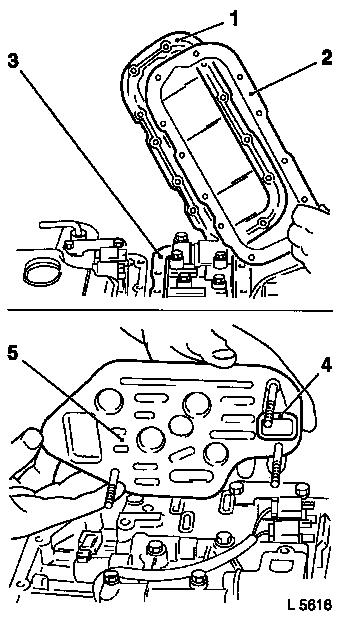

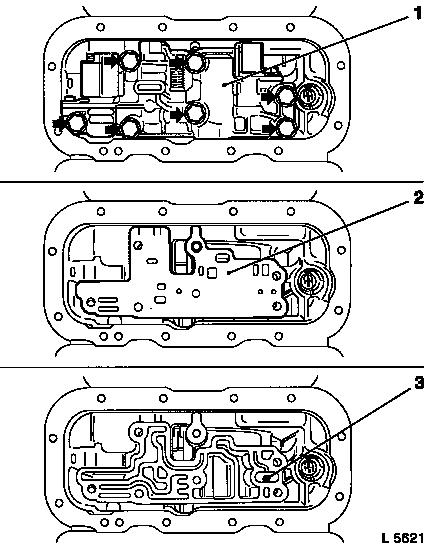

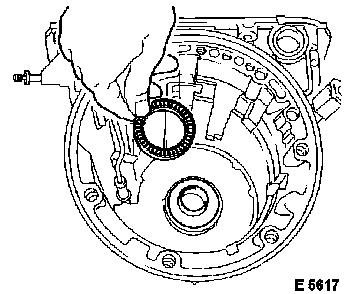

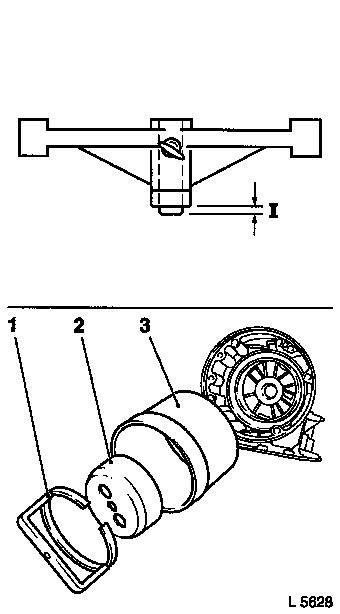

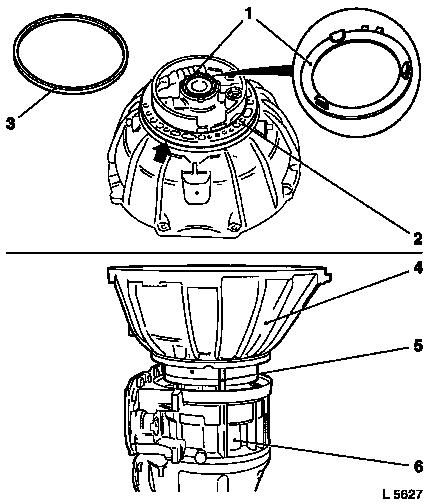

Survey of Assemblies, AR 25/35

Illustration shows torque converter

for 4- and 6-cylinder petrol engines.

|

1

|

Torque converter with converter clutch

|

|

2

|

Fastening bolt, seal ring/converter housing

|

|

3

|

Seal ring, converter housing

|

|

4

|

Fastening bolt, converter housing/transmission casing

|

|

5

|

Fastening bolt, converter housing/fluid pump (x 5)

|

|

6

|

Converter housing

|

|

7

|

Closure screw, fluid pressure checking bore hole

|

|

8

|

O-ring

|

|

9

|

Support plate, fluid pump

|

|

10

|

Fluid pump

|

|

11

|

Gasket

|

|

12

|

Thrust washer (selectable)

|

|

13

|

Retaining ring

|

|

14

|

Closure cap, 3/4 accumulator

|

|

|

|

Survey of Assemblies, AR 25/35

(Continued)

|

16

|

Spring for piston, 3/4 accumulator

|

|

18

|

Piston, 3/4 accumulator

|

|

19

|

Seal ring for piston, accumulator

|

|

20

|

Intermediate housing

|

|

22

|

Connector, intermediate housing

|

|

23

|

Fastening bolt

|

|

27

|

Throttle

|

|

28

|

Gasket, support plate

|

|

29

|

Support plate, centre support

|

|

30

|

Centre support

|

|

31

|

Fastening bolt

|

|

32

|

Seal ring, centre support

|

|

33

|

O-ring, transmission housing

|

|

|

|

Survey of Assemblies, AR 25/35

(Continued)

|

34

|

Connection, fluid cooler line (transmission outlet)

|

|

36

|

Transmission housing

|

|

37

|

Vent

|

|

38

|

Seal ring, fluid reservoir

|

|

39

|

Fluid reservoir

|

|

42

|

Gasket, nose piece

|

|

43

|

Nose piece

|

|

44

|

O-ring, sensor

|

|

45

|

Transmission output speed sensor

|

|

46

|

Fastening bolt

|

|

47

|

Fastening nut, output flange

|

|

48

|

O-ring, output flange

|

|

49

|

Output flange

|

|

50

|

Seal ring, nose piece

|

|

51

|

Radial needle roller bearing

|

|

|

|

Survey of Assemblies, AR 25/35

(Continued)

|

52

|

Fastening bolt, extension (x 7)

|

|

55

|

Connector, transmission housing

|

|

67

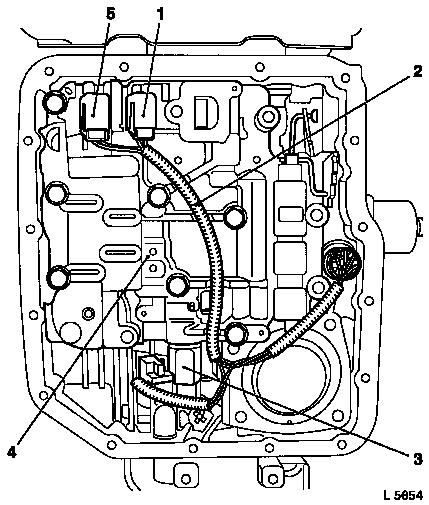

|

Transmission fluid pan, intermediate housing

|

|

68

|

Gasket, intermediate housing

|

|

69

|

Wiring harness, intermediate housing

|

|

70

|

Fastening bolt, valve body assembly (x 19)

|

|

71

|

Valve body assembly, intermediate housing

|

|

72

|

Gasket

|

|

73

|

Support plate

|

|

74

|

Transmission fluid pan, transmission housing

|

|

75

|

Gasket, transmission housing

|

|

78

|

Fixing magnet

|

|

|

|

Survey of Assemblies, AR 25/35

(Continued)

|

79

|

Fluid strainer

|

|

80

|

Wiring harness, transmission housing

|

|

81

|

Bracket

|

|

82

|

Detent spring

|

|

84

|

Valve body assembly

|

|

85

|

Valve balls (2 balls on underside of transmission housings, 1

ball in transmission housing valve body, 1 ball on underside of

intermediate housings)

|

|

|

|

Survey of Assemblies, AR 25/35

(Continued)

|

86

|

Gasket

|

|

87

|

Support plate

|

|

88

|

Gasket

|

|

89

|

Fastening bolt, support plate (x 2)

|

|

90

|

Fastening bolt, brake band servo cover (x 4)

|

|

91

|

Brake band servo cover

|

|

92

|

Gasket

|

|

93

|

Retaining ring

|

|

94

|

Retaining clamp

|

|

95

|

Lock nut

|

|

96

|

Adjustment bolt

|

|

|

|

Survey of Assemblies, AR 25/35

(Continued)

|

97

|

Brake band servo piston

|

|

98

|

Piston ring

|

|

99

|

Cushion spring

|

|

100

|

Seat, damping spring

|

|

101

|

Sleeve

|

|

102

|

Cam follower

|

|

103

|

Relief spring, servo piston

|

|

104

|

Gasket, support plate/intermediate housing

|

|

|

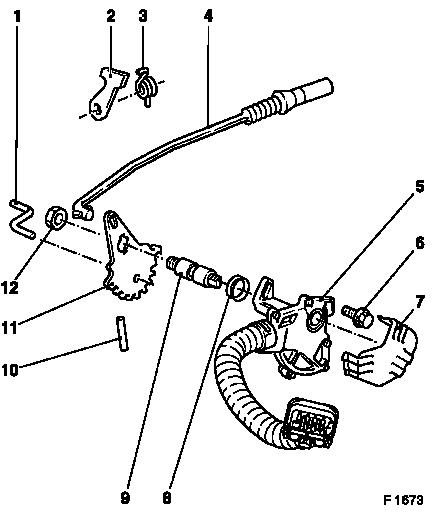

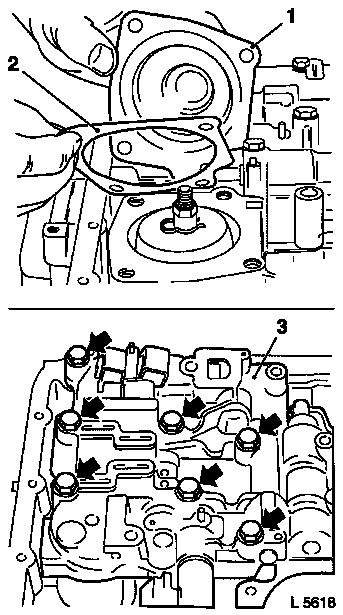

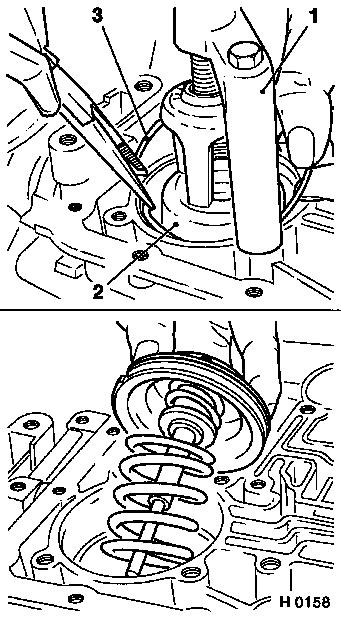

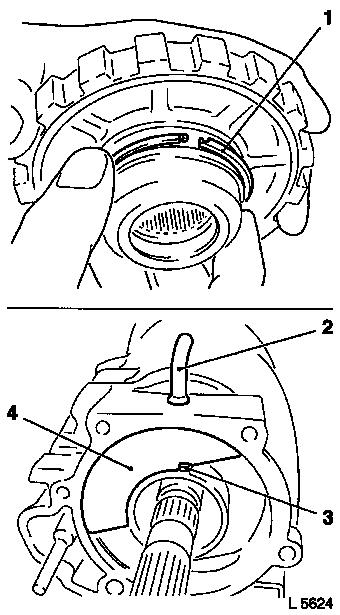

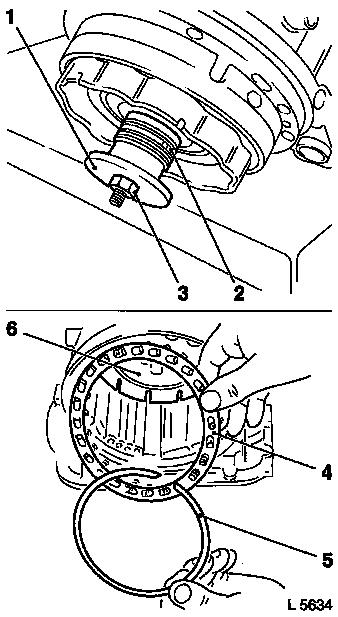

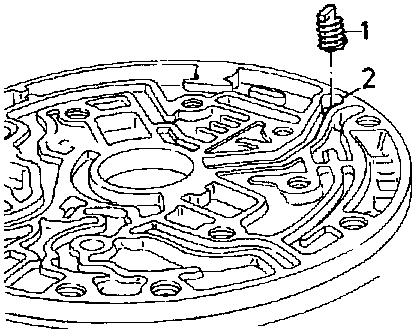

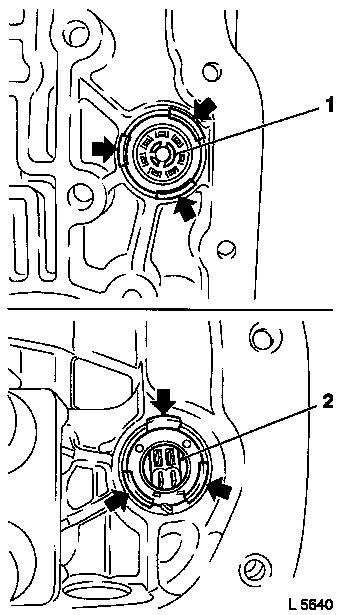

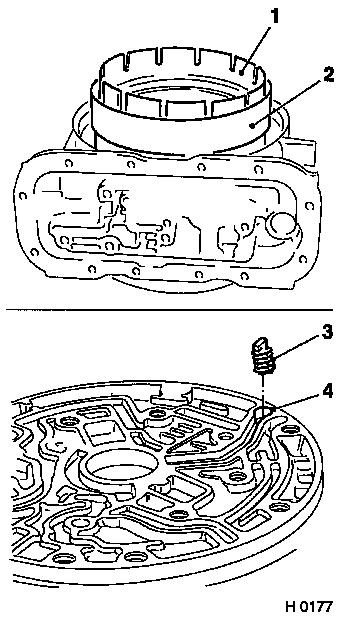

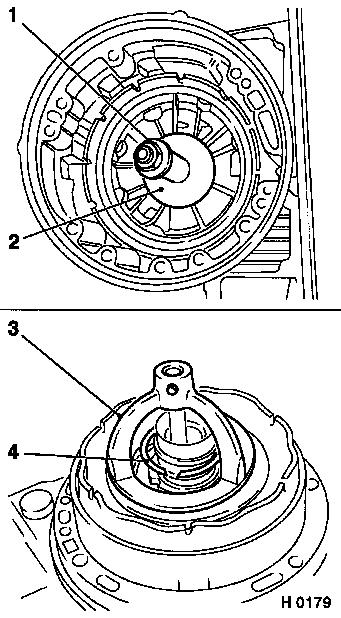

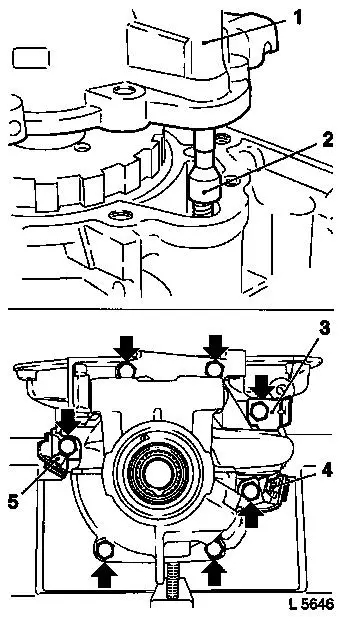

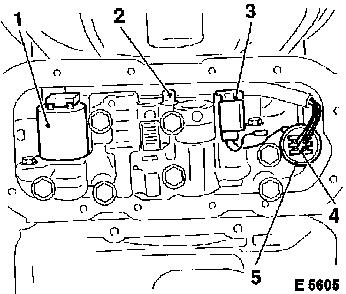

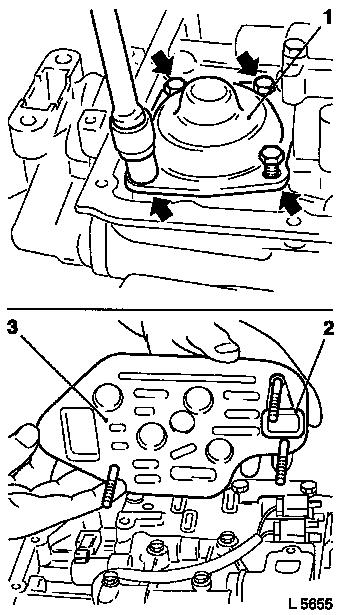

Illustration

|

Automatic transmission AR 25/35,

parking lock and selector lever position switch

|

1

|

Control lever

|

|

2

|

Pawl

|

|

3

|

Retaining spring

|

|

4

|

Actuation rod, parking lock

|

|

5

|

Selector lever position switch

|

|

6

|

Fastening bolt (x 2)

|

|

7

|

Cover plate

|

|

8

|

Seal ring

|

|

9

|

Transmission selector lever shaft

|

|

10

|

Roll pin

|

|

11

|

Shift segment

|

|

12

|

Fastening nut

|

|

|

Remove Remove

Remove transmission – see operation "Automatic

Transmission, Remove and Install (Vehicles with 4-Cylinder Petrol

Engine)", "Automatic Transmission, Remove and Install (Vehicles

with V6 Engine)", "Automatic Transmission, Remove and Install

(Vehicles with Diesel Engine)".

Note: During all

operations on automatic transmission ensure utmost cleanliness of

the components and tools. Malfunctioning of the transmission is

often caused by dirt and foreign objects.

Caution

|

Converter contains a large amount of transmission fluid.

Transmission fluid escapes. Place collecting basin

underneath.

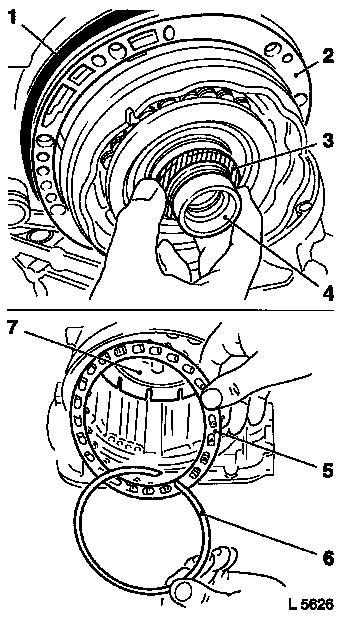

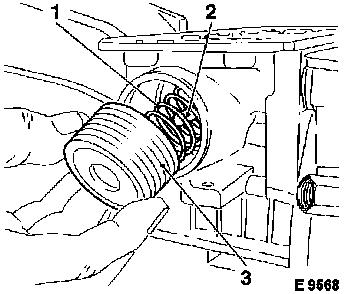

Remove Remove

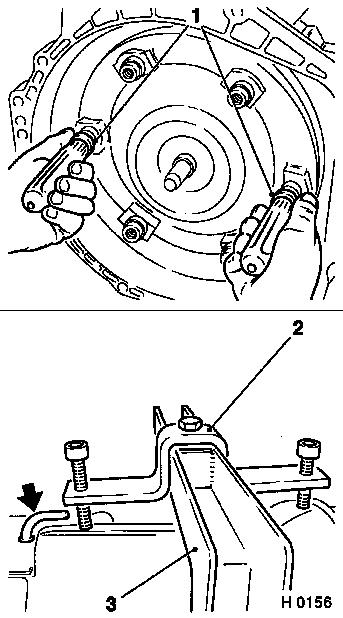

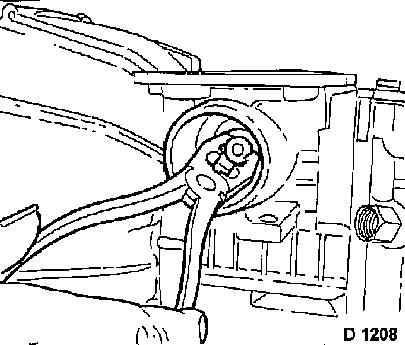

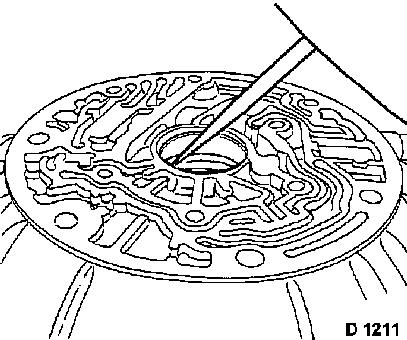

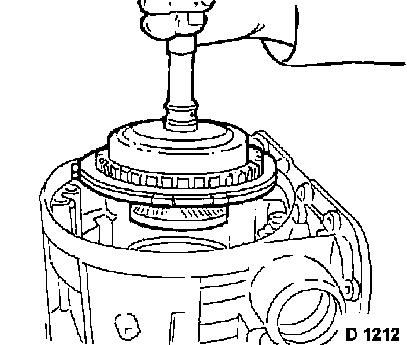

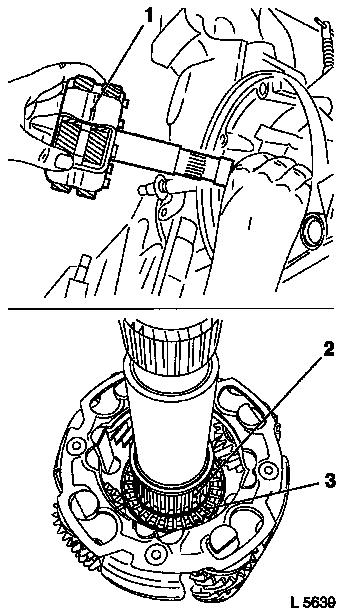

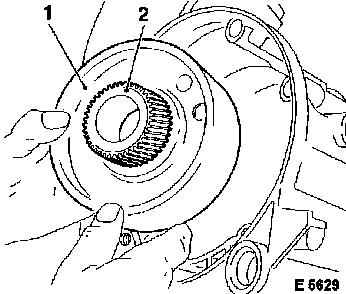

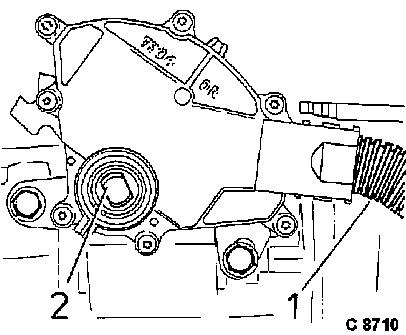

Remove converter with KM-574 (1) or KM-899 (vehicles with diesel

engine) from converter housing.

Install

Install

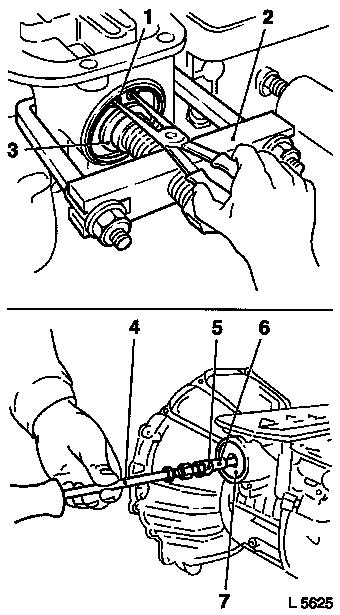

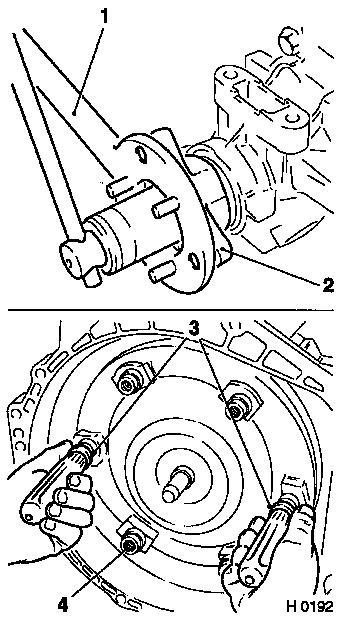

Attach KM-113-A (3) in conjunction with KM-113-5 (2) to

transmission.

Attach assemblies to KM-113-2.

Install short arm of KM-113-5 towards output side, so that vent

line (arrow) remains free.

|

|

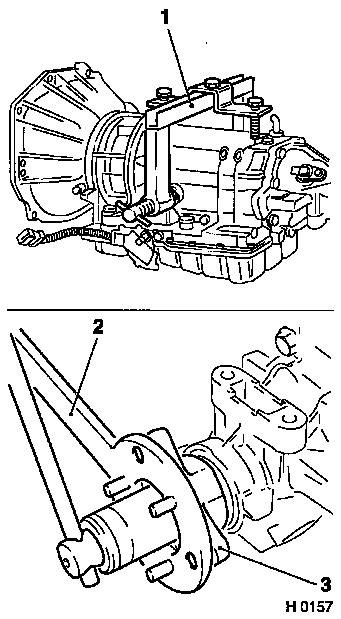

Caution

|

Do not press too heavily on transmission holder (1), since

otherwise the assemblies cannot be removed – the transmission

housing would be deformed.

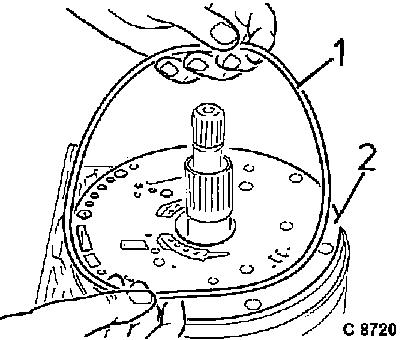

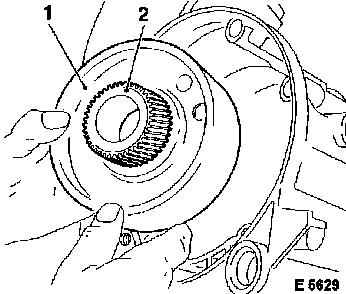

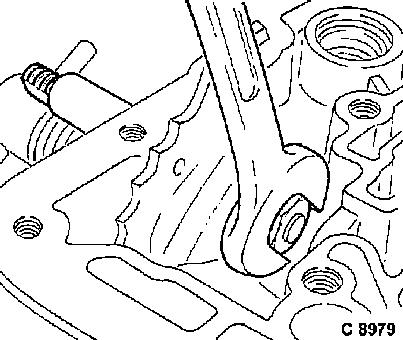

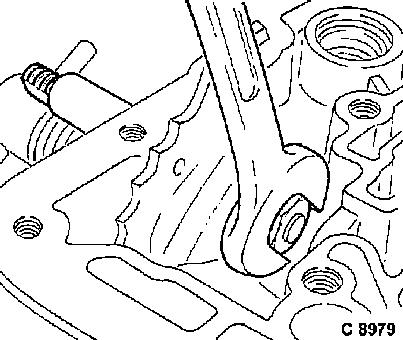

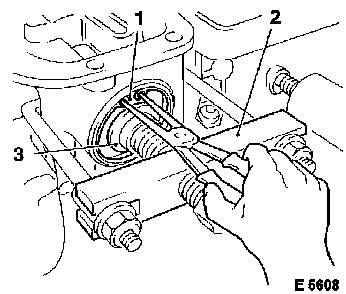

Remove Remove

Remove fastening nut for output flange (socket A/F 30, extra

long), counterhold with KM-623 (2).

Detach output flange (3) from the output shaft. If stiff, detach

with KM-628-A.

Inspect

Inspect

Check O-ring of output flange for wear and damage, replace if

necessary.

|

|

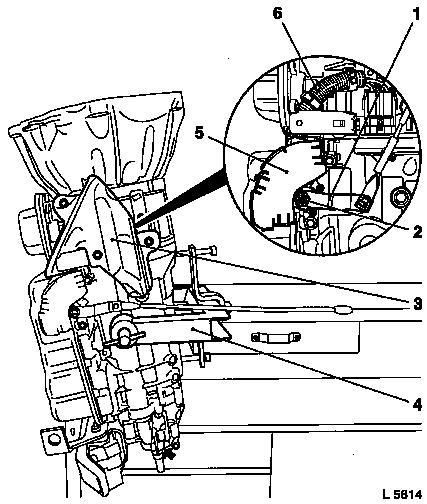

Caution

|

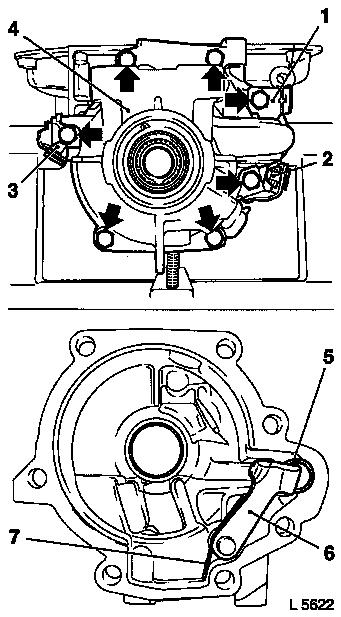

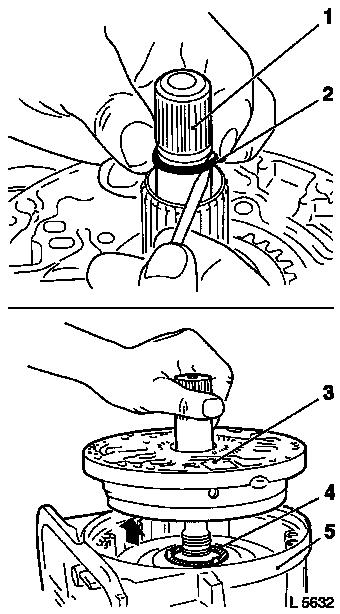

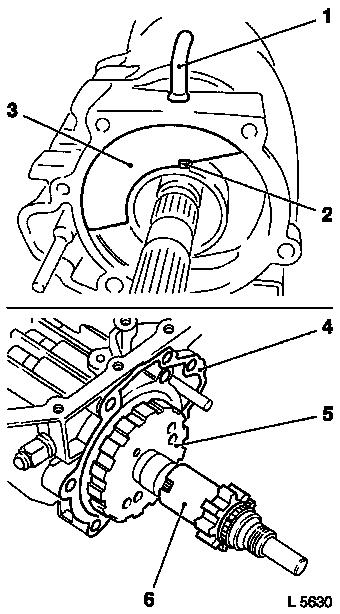

Turn transmission carefully with KM-113-A (4), so that any dirt

present (shavings) cannot fall into the valve body.

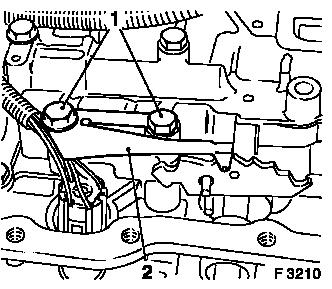

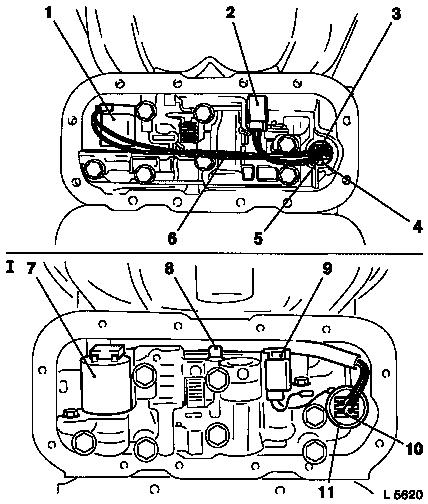

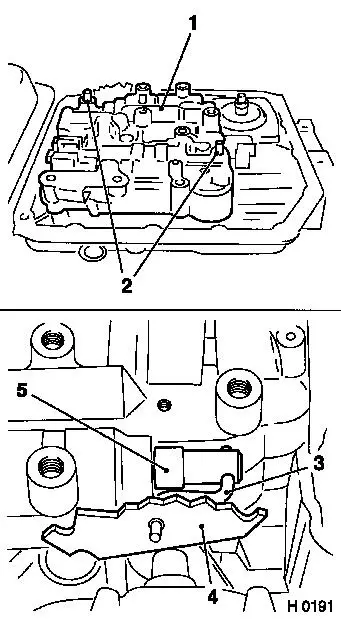

Remove Remove

Converter housing points upwards.

Drain remaining transmission fluid through extension

(arrow).

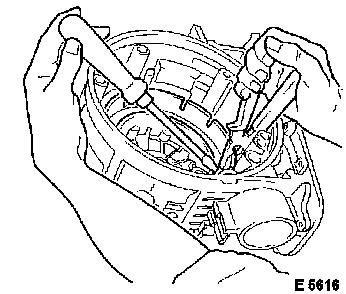

Remove heat shield (3) for selector lever position switch (3

fastening bolts).

Remove selector intermediate lever (1) from the transmission

selector lever shaft (2) (1 fastening nut).

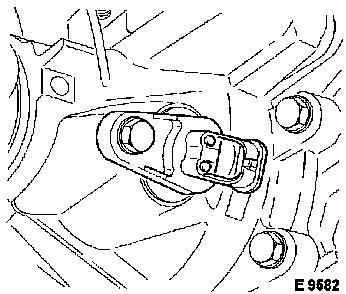

Detach selector lever position switch with shield (5) and wiring

harness (6) from the transmission selector lever shaft (2 fastening

bolts).

|

|

|

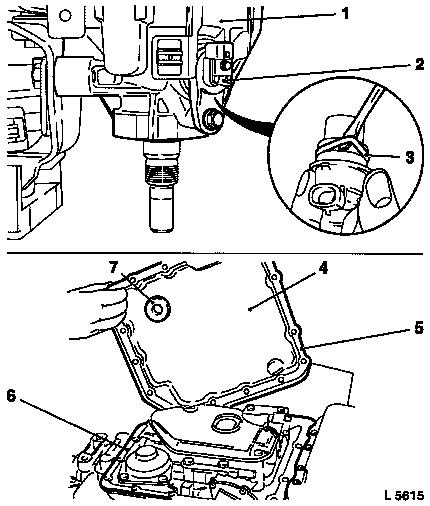

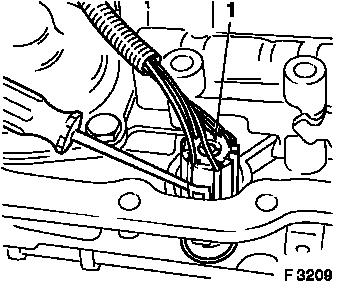

Detach transmission output speed sensor (2) from transmission

extension (1) (1 fastening bolt).

Inspect

Inspect

Replace O-ring (3) in transmission output speed sensor.

Remove Remove

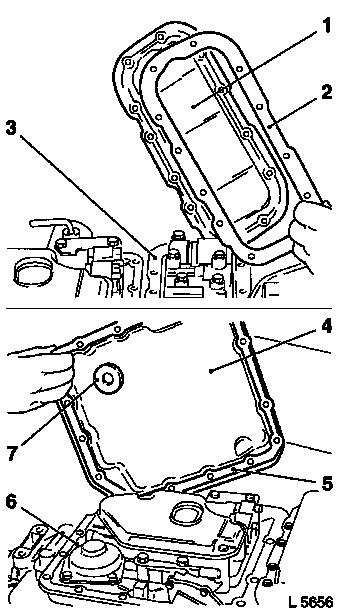

Turn transmission – transmission fluid pans point upwards.

Detach transmission fluid pan (4) and gasket (5) from transmission

main casing (6) (16 fastening bolts).

Clean Clean

Remove fixing magnet (7) from the transmission fluid pan. Clean

inside of transmission fluid pan, transmission fluid pan sealing

surfaces and fixing magnet.

|

|

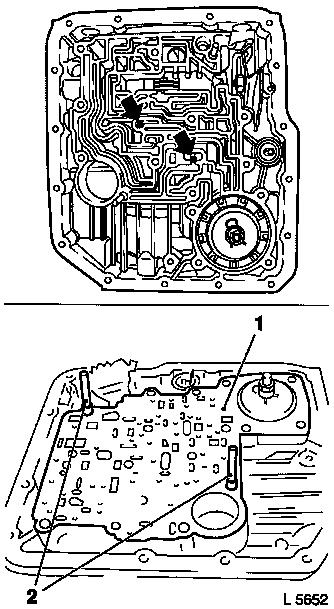

Remove Remove

|

Detach transmission fluid pan (1) and gasket (2) from

transmission intermediate casing (3) (12 fastening bolts).

Clean Clean

Clean transmission fluid pan sealing surface and inside of

transmission fluid pan.

Remove Remove

Detach fluid screen (5) with stuck-on gasket (4) (3 fastening

bolts).

|

|

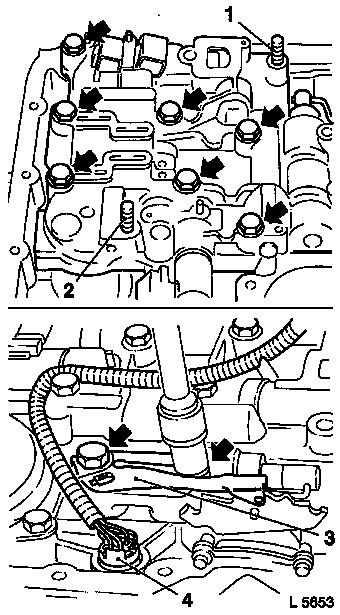

|

Remove fastening bolts (1) and remove detent spring (2).

|

|

|

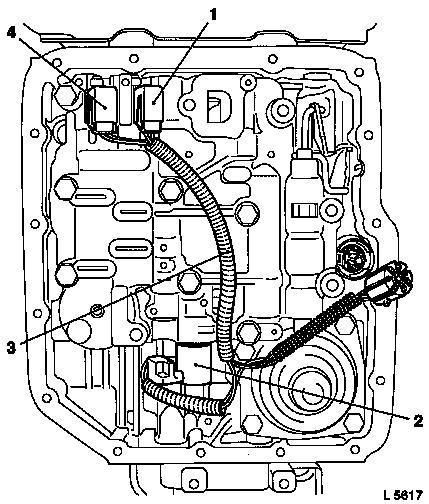

Caution

Do not pull on wiring harness.

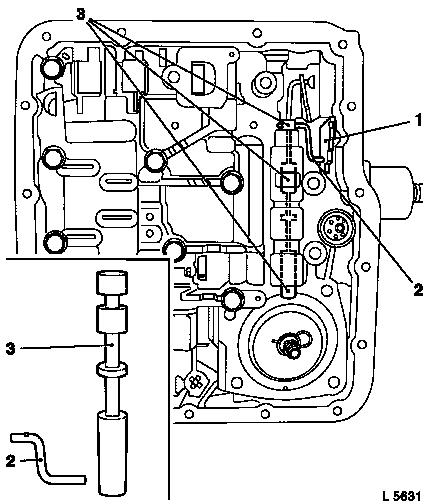

Remove Remove

Carefully release 7-pin wiring harness plug (1) for solenoid

valves from transmission housing connection plug with small

screwdriver and disconnect.

|

|

Caution

|

Do not pull on the cables of the wiring harness.

Remove Remove

Detach plug connection at solenoid valve (2) for brake band

servo.

Detach plug connection at solenoid valve (4) for 1/2 shifting

and 3/4 shifting.

Detach plug connection at solenoid valve (1) for 2/3

shifting.

Remove wiring harness (3) for main casing valve body.

|

|

|

Detach brake band servo cover (1) and gasket (2) (4 fastening

bolts).

Detach fastening bolts (arrows) for valve body assembly (3).

|

|

|

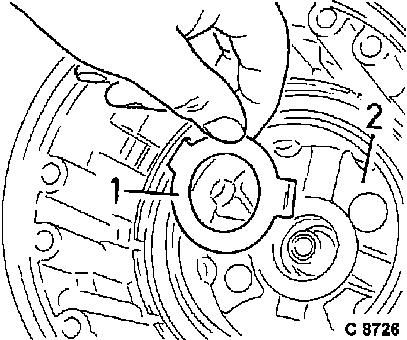

Lift valve body assembly and detach control lever (2) for shift

valve (3) on shift segment (1).

Remove valve body assembly with intermediate plate and gasket.

Do not reuse gasket.

Remove shift valve (2) with control lever (1) from valve body

assembly.

Note position of control lever (1). Long end points towards

selector valve (2).

|

|

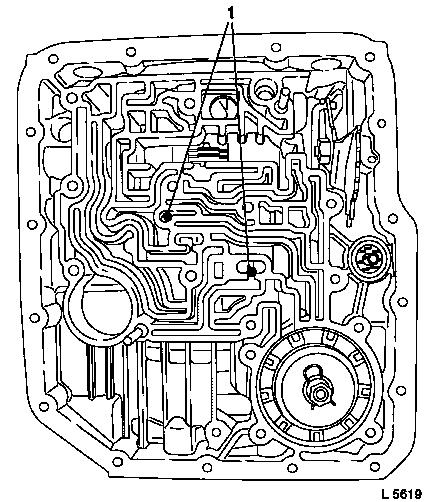

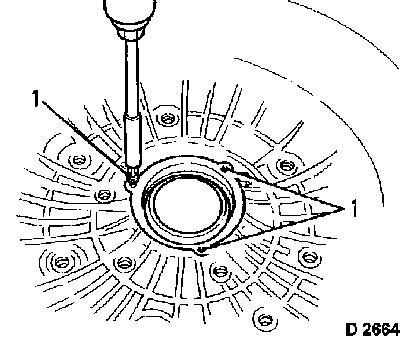

Caution

|

Do not lose valve balls.

To remove, do not use any magnets because the valve balls will

become magnetic and will attract any resulting shavings, which may

lead to leaks in the fluid circuit in question or to

malfunctions.

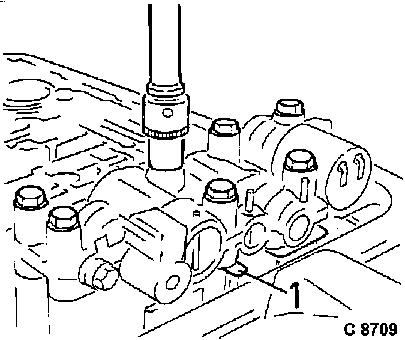

Remove Remove

Remove valve balls (1) from the fluid ducts of the transmission

main casing.

|

|

Caution

|

Do not pull on the cables of the wiring harness.

Remove Remove

Detach plug connection at solenoid valve for pressure regulator

(1).

Detach plug connection at solenoid valve for converter clutch

(2).

Detach wiring harness plug (5) from connection plug (4) on

intermediate casing.

Remove wiring harness for intermediate casing valve body

(6).

If present (L 5620 I), pull out sheathed part of wiring harness

until wiring harness plug for pressure regulator solenoid valve (7)

can be removed past the retaining lug (8).

|

|

|

Detach fastening bolts (arrows) for valve body assembly (1) from

intermediate casing.

Detach valve body assembly with support plate (2) and both

gaskets beneath.

Caution

Do not lose valve ball.

To remove, do not use any magnets because the valve ball will

become magnetic and will attract any resulting shavings, which may

lead to leaks in the fluid circuit in question or to

malfunctions.

Remove Remove

Remove valve body (3) from the fluid duct of the transmission

intermediate casing.

|

|

|

Remove servo piston assembly (2).

Attach KM-J-23075-A (1) to transmission casing. KM-J-23075-A has

a symmetrical design, attach in the position shown.

Compress relief spring for brake band servo piston with spring

compressor. Slowly relieve tension on KM-J-23075-A (high spring

tension) and remove.

Remove retaining ring (3) and remove servo piston assembly.

Inspect

Inspect

Check servo piston assembly for wear and damage, replace with

new parts, if necessary.

|

|

Remove Remove

|

Detach fastening bolts (arrows) and wiring harness bracket (1, 2

and 3) if fitted.

Detach transmission extension (4) with gasket below from

transmission casing.

Remove pawl (6) for parking lock with retaining spring (7) from

transmission extension.

Inspect

Inspect

Check liner (5), pawl and retaining spring for wear and damage,

replace if necessary.

|

|

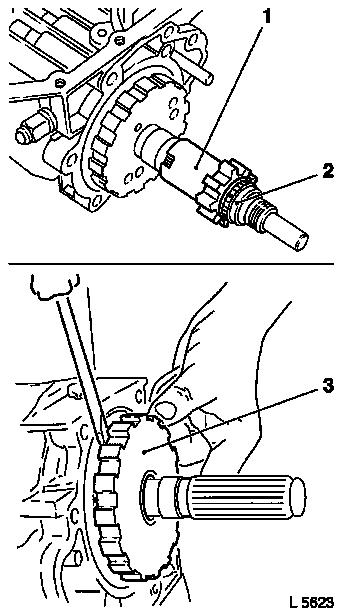

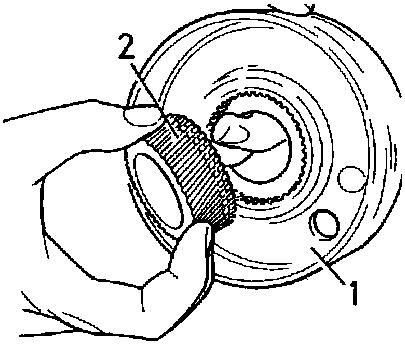

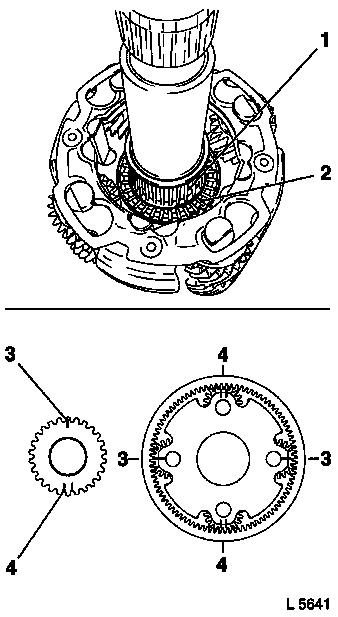

Remove Remove

|

Detach pulse pickup (1) for output speed sensor from the output

shaft (2).

Detach parking lock gear (3) from output shaft using

screwdriver.

|

|

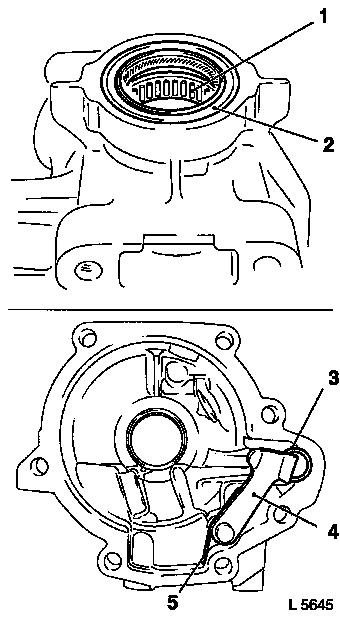

Inspect

Inspect

|

Check parking lock gear for wear and damage.

Check hook seal ring (1) on hub of parking lock gear for

breakage and wear, replace if necessary.

Remove Remove

Clamp vent pipe (2) with pliers and remove from transmission

casing. Avoid damage.

Remove fluid reservoir (4). Installation position is determined

by the guide (3).

|

|

|

Attach KM-686-1 (2) and KM-469-14 (3) to the intermediate casing

to remove the 3/4 accumulator piston. The short side of remover

bridge points to the converter housing.

Compress accumulator spring with KM-469-14 (3) until the

retaining ring is free. Remove retaining ring (1) – do not

damage ring groove in the process.

Relieve tension on KM-686-1 and detach.

Remove closure cap (7) for the accumulator piston with KM-686-2

(5) in conjunction with KM-838 (6) and KM-J-7004 (4).

Prevent tilting of the closure cap by aligning the tools at an

angle.

Release closure cap with light taps of a soft metal drift and

plastic hammer.

|

|

|

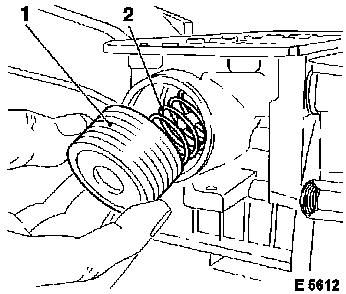

Remove closure cap (1) and spring (2) for accumulator

piston.

|

|

|

Remove pin using suitable pliers.

|

|

Remove Remove

|

Remove piston for 3/4 accumulator using pliers.

Doing this, do not tilt piston.

|

|

|

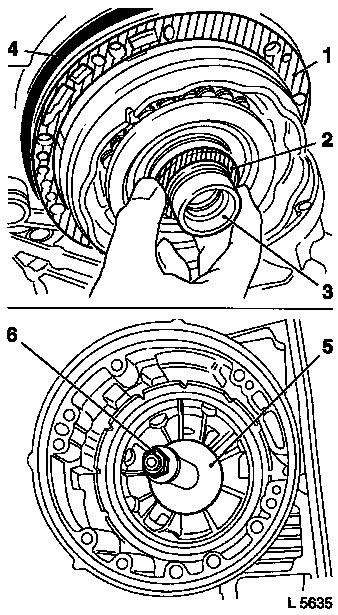

For further disassembly, turn transmission in adapter by 90°

(converter housing upwards).

Release cover of seal ring for fluid pump (3 fastening

bolts).

|

|

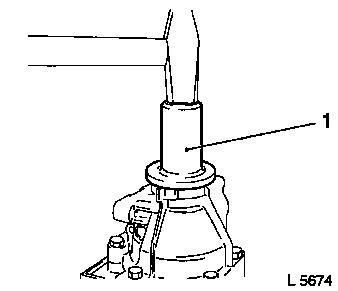

Remove Remove

|

Drive seal ring out of converter housing with KM-J-23129 or

KM-586 (1) in conjunction with KM-J-7004 (2).

If seal ring is difficult to remove, remove after removal of

converter housing.

|

|

|

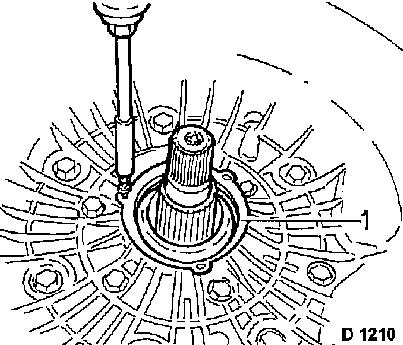

Detach fastening bolts for converter housing (outer screw circle

– 7 fastening bolts).

Detach fastening bolts for fluid pump (inner screw circle

– 5 fastening bolts).

Detach converter housing from intermediate casing by gently

turning back and forth, as well as from drive shaft and fluid pump

shaft (1).

|

|

|

Note: Operation is

only necessary if seal ring in converter housing could not be

removed using KM-J-23129 or KM-586.

Remove Remove

Drive out seal ring from converter housing using suitable

screwdriver.

|

|

|

Detach seal ring (1) from intermediate casing. Seal ring is not

re-used.

Lift support plate (2) off fluid pump and remove.

|

|

|

Detach O-ring (2) from drive shaft (1). O-ring is not

re-used.

Remove fluid pump (3) from intermediate casing (5).

Detach gasket (arrow) from fluid pump. Gasket is not

re-used.

Remove thrust washer (4, optional).

|

|

|

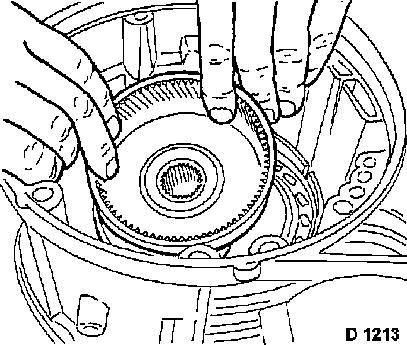

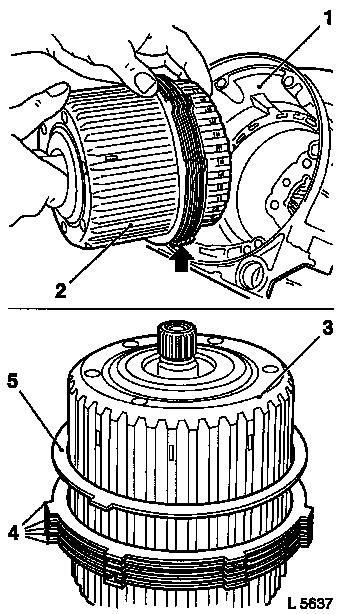

Remove thrust ring (1) for 4th gear clutch and overrunning

clutch assembly with clutch discs from intermediate casing.

|

|

|

Detach clutch discs.

Steel plates: x 4.

Lining plates: x 2.

One steel plate remains in the casing, remove this as well.

Caution

If clutch plates are not being replaced, install in original

position. See also "Technical Data" for number of steel and lining

plates.

|

|

Remove Remove

|

Remove hollow gear from the intermediate casing.

|

|

|

Remove thrust washer (1) from intermediate casing (2).

|

|

|

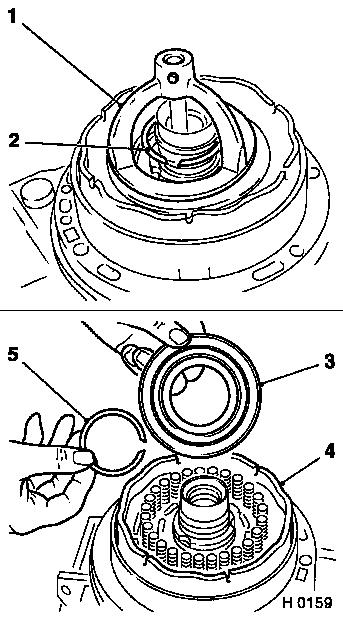

Remove intermediate casing (1) with piston for 4th gear clutch,

centre support and piston for reverse clutch from transmission

casing (2).

Place KM-680-A (3) on spring set seat (5) in intermediate

casing.

Insert KM-J-23078-A (4) through KM-680-A and the bore hole in

the intermediate casing so that the thread piece protrudes at

rear.

|

|

|

Position sleeve of KM-J-23078-A (1) at centre support hub (2)

and compress KM-J-23078-A using fastening nut (3) until retaining

ring for spring set seat is free.

Remove retaining ring out of ring groove using suitable

screwdriver.

Relieve tension on KM-J-23078-A and detach. Detach KM-680-A.

Detach retaining ring (5) and spring set seat (4) with relief

springs from clutch piston (6).

Note: Relief springs

can only be replaced in assembly with spring set seat.

|

|

Remove Remove

|

Optionally detach thrust washer (2) from centre support hub

(3).

Detach gasket (1) and seal ring (4) from intermediate casing.

Gasket and seal ring are not re-used.

Attach KM-J-23078-A to the reverse clutch.

Attach sleeve (5) at the inside of the intermediate casing to

the clutch piston.

Compress the relief springs using the fastening nut (6) until

the retaining ring is free on the rear of the intermediate

casing.

|

|

|

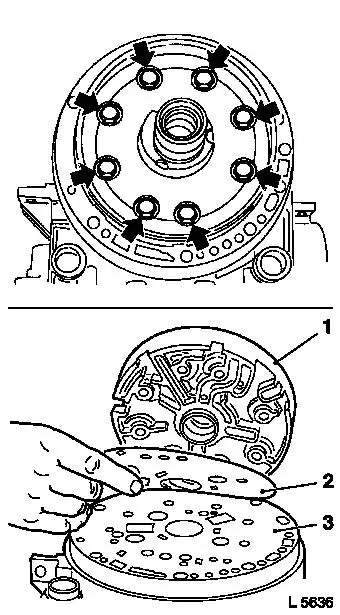

Turn intermediate housing upside down.

Remove retaining ring (2) from the groove with KM-396.

Relieve tension on KM-J-23078-A (1) and detach.

Detach retaining ring (5).

Detach seat (3) for relief springs and 24 relief springs from

reverse clutch.

Remove clutch piston (4) from intermediate housing.

|

|

|

Detach 8 fastening bolts (arrows) for centre support.

Remove centre support (1), gasket (2), support plate (3) and

gasket underneath support plate. Do not reuse gaskets.

Note: Corresponding

installation position is predetermined by bore holes. Support plate

and gaskets are available as a set.

|

|

Remove Remove

|

Remove throttle (1) from the bore (2) in the intermediate

casing. Inspect throttle, replace if necessary.

|

|

|

Remove clutch piston for 4th gear clutch out of intermediate

casing with pliers and lever.

Replace inner and outer seal ring on piston for reverse gear

clutch and 4th gear clutch. Sealing lip of seal rings always points

towards piston crown.

|

|

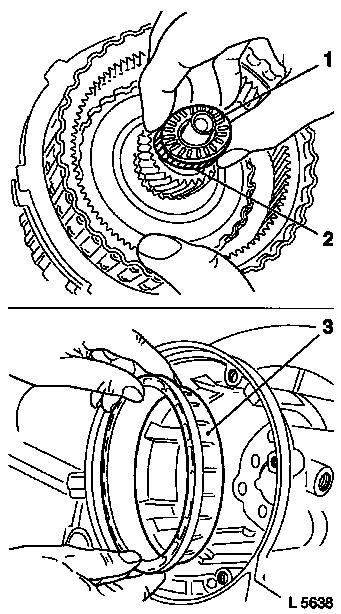

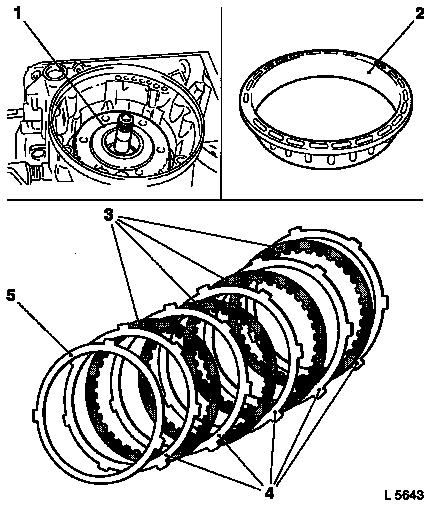

Remove Remove

|

Remove assembly of 2nd and 3rd gear clutch (2) with clutch discs

(arrows) for the reverse gear from the transmission casing (1).

Detach clutch discs from assembly (3).

Damping cushion: x 1 (5)

Steel plates: x 5 (4)

Lining plates: x 4.

If clutch plates are not being replaced, install in original

position. See also "Technical Data" for number of steel and lining

plates.

|

|

|

Detach the freed axial needle bearing (1) with washer (2) from

2nd and 3rd gear clutch assembly.

Caution

Note installation position of bearing.

Remove Remove

Remove thrust ring (3) for reverse clutch from the transmission

casing.

|

|

|

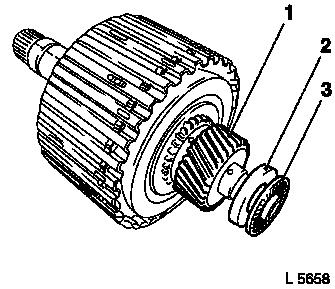

Remove planetary carrier (1) from the transmission casing.

Inspect

Inspect

Check the axial needle bearing (3) and the radial needle bearing

(2) of the planetary carrier. The needle bearings are fitted

securely on the output shaft, if defective the planetary carrier

must be replaced.

|

|

Remove Remove

|

Remove brake band drum (1) with rear sun gear (2) from

transmission housing.

|

|

|

Detach rear sun gear (2) from brake band drum (1).

|

|

|

Detach brake band at retaining lug and remove from transmission

casing.

|

|

|

Remove freed bearing (one-piece axial needle bearing with thrust

washer) from transmission casing.

Note installation position of bearing. This bearing may have

remained on the output side of the brake band drum.

|

|

|

Note: If transmission

selector lever shaft or seal ring for transmission selector lever

shaft are damaged:

Remove Remove

In the transmission casing, detach fastening nut from the

transmission selector lever shaft.

If necessary, remove actuating rod for parking lock.

|

|

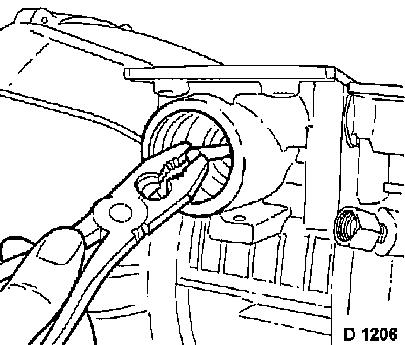

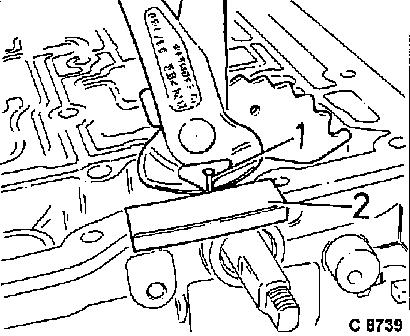

|

Remove roll pin using pliers.

For this purpose, insert nail (1) with suitable diameter into

roll pin, so that the latter is not sheared off when being pulled

out.

Use sheet metal (2) as pad to avoid damage to sealing surface of

transmission housing.

|

|

Detach shift segment from transmission selector lever shaft.

Check transmission selector lever shaft for burrs before removal

to avoid damage to seal ring.

Remove transmission selector lever shaft, if stiff press out

from inside with hammer handle. Check seal ring for wear and

damage, replace if necessary.

Install

Install

|

Install transmission selector lever shaft. If removed: connect

actuating rod for parking lock.

Insert transmission selector lever shaft, note installation

position (groove for roll pin).

Drive in new roll pin only so far that later removal remains

possible – transmission selector lever shaft must be free to

move.

Torque

Fastening nut to shift segment – 22 Nm / 16 lbf. ft.

|

|

Remove Remove

|

Remove connection plug (1) on main casing and connection plug

(2) on intermediate casing by pressing back the lugs (arrows) with

a screwdriver.

Inspect

Inspect

Check O-rings and connection plugs for damage, replace if

necessary.

Install

Install

Reinstall both connecting plugs without damaging O-rings.

Caution

On replacing the connecting plug on the main housing – see

operation "Adapter Piece at Main Housing, Replace".

|

|

Assemble

Assemble

|

Install brake band in transmission casing.

Install brake band, so that valve lifter of the brake band servo

piston can be installed for proper functioning.

|

|

|

Install bearing (one-piece axial needle bearing with thrust

washer).

Housing sleeve serves as guide for thrust washer and

bearing.

|

|

|

Install sun gear (2) into brake band drum (1).

|

|

|

Install brake band drum (1) with sun gear (2) in transmission

casing.

|

|

|

Note: Before further

assembly, turn transmission in adapter by 90°.

Assemble

Assemble

Insert KM-689 (1) into transmission casing.

Insert relief spring for servo piston.

|

|

|

Insert servo piston assembly (1) and retaining ring into

KM-689.

Caution

If necessary, rework supports of KM-J-23075-A (3) at points

marked with arrows, so that these can be moved over KM-689 (2).

Assemble

Assemble

KM-J-23075-A has an asymmetrical design. Attach KM-J-23075-A in

the position shown on transmission casing. Compress relief spring

for brake band servo piston with KM-J-23075-A until ring groove is

free.

|

|

|

Install retaining ring. Ensure it is correctly seated.

Relieve tension on KM-J-23075-A (1) and detach.

Detach KM-689 (2).

Adjust Adjust

Adjust brake band: Release lock nut (5) at adjustment bolt.

Tighten adjustment bolt with MKM-111 (3) and MKM-J-6459-B (4) to

the prescribed torque of 5 Nm / 4 lbf. ft.

Hold sleeve and turn adjusting screw back 5 turns.

Remove insert and torque wrench.

Tighten lock nut with sleeve held in position – tightening

torque 20 Nm / 15 lbf. ft.

|

|

Inspect

Inspect

|

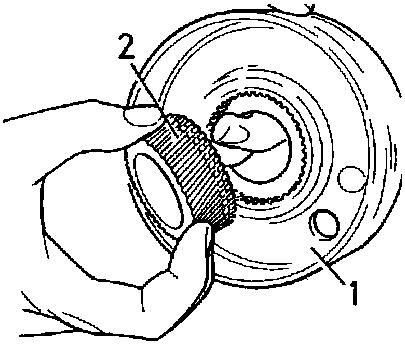

Check axial needle bearing (2) and radial needle bearing (1) in

the planetary carrier for damage or wear.

Caution

On installation, do not let planetary carrier fall into sun gear

of brake band drum, since these bearings can be damaged.

Before inserting planetary carrier

align markings on planetary gears to markings on planetary

carrier.

|

3

|

One line marking

|

|

4

|

Two line marking

|

Assemble

Assemble

Install planetary carrier carefully in transmission casing.

|

|

|

Place axial needle bearing (3) with washer (2) (note

installation position) onto input sun gear (1) of 3rd gear

clutch.

In order to fix, adhere bearing and washer with installation

grease.

|

|

|

Install 2nd and 3rd gear clutch assembly (1) into transmission

housing.

Caution

If any components are defective, use complete set with lining

and steel plates and thrust ring.

Insert thrust ring (2) for reverse clutch with collar side

outwards. Alternately insert steel plates (4) and lining plates

(3). Insert damping cushion (5).

|

|

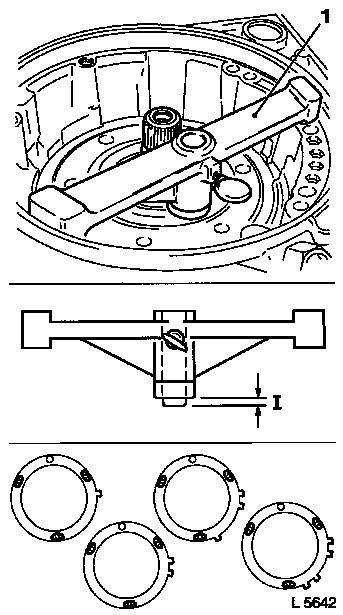

Measure

Measure

|

Installation height of 2nd gear clutch

relative to transmission housing:

- Attach KM-J-23085-A to flange of transmission casing.

- Loosen locking screw and install inner shaft on clutch hub

contact surface.

- Tighten locking screw and remove Measuring Gauge

KM-J-23085-A.

Remove dimension "I" (illustration H

0176) at the measurement gauge (1) and select the relevant thrust

washer. The relevant washers are available via the "Aftersales"

division.

|

Transmission end play (compensation by thrust washer)

|

|

Identifier for dimension "I" of measurement operations

|

|

old version

|

new version

|

|

yellow

|

-

|

|

red

|

1 lug (1.72/1.82 mm)

|

|

black

|

2 lugs (1.91/2.01 mm)

|

|

clear, white

|

3 lugs (2.10/2.20 mm)

|

|

green

|

4 lugs (2.29/2.39 mm)

|

|

blue

|

-

|

|

|

Caution

|

Do not exceed dimension "I" with selected pressure plate, i.e.

preferably use the next smaller plate.

Assemble

Assemble

Install clutch piston for 4th gear using KM-680-A (1) to hold

down spring set and using KM-837 (2) and KM-684 (3) to protect

piston seal rings.

|

|

|

Insert clutch piston (1) for 4th gear clutch into KM-684

(2).

Slide KM-684 and KM-837 onto the clutch piston to protect the

outer and inner seal ring.

Coat sealing lips of sealing rings with transmission fluid or

installation grease.

Install clutch piston with KM-680-A in intermediate casing.

Remove KM-684 and KM-837.

Install throttle (3) in bore (4) in intermediate casing. Place

lug of throttle in the fluid duct.

|

|

|

Attach KM-678 (3) to intermediate casing (2). Place support

plate (1) on intermediate casing with one gasket on each side.

Note: Support plate

and gaskets are available as a set. Installation position is

determined by bore holes.

Inspect

Inspect

Check seal rings on hub of centre support for wear and lateral

play, replace if necessary.

Assemble

Assemble

Attach centre support (4) loosely to intermediate casing (6

fastening bolts). Installation position is determined by the hole

pattern.

Detach KM-678, insert the remaining fastening bolts.

Tighten all fastening bolts – tightening torque 23 Nm / 17

lbf. ft.

|

|

|

Install clutch piston (2) of reverse clutch in conjunction with

Protective Sleeve KM-233-A (1) in the centre support.

Caution

Coat sealing lips of seal rings with transmission fluid or

installation grease.

Remove Protective Sleeve KM-233-A.

Assemble

Assemble

Install relief springs (x 24) in clutch piston (4).

Carefully insert intermediate ring (3) for release springs and

retaining ring (5) so that release springs are correctly

positioned.

|

|

|

Attach KM-J-23087-A (3) to the reverse clutch.

Place sleeve (2) inside intermediate housing on clutch

piston.

Compress relief springs with fastening nut (1) until the groove

for retaining ring on the rear of the intermediate casing is

free.

Turn intermediate housing.

Install retaining ring (4) with KM-396 in groove.

Relieve tension on KM-J-23087-A and detach.

|

|

|

Coat selected thrust washer (3) with installation grease and

slide on hub (4) of centre support.

Attach seal ring (1).

Attach gasket (2) – installation position is determined by

the hole pattern.

Place spring set seat with relief springs (5) onto clutch piston

(7).

Insert retaining ring (6).

|

|

|

Place KM-680-A (1) on the spring set seat (3) in intermediate

casing.

Guide KM-J-23078 (2) through KM-680-A and bore hole in

intermediate casing, so that threaded piece protrudes at rear.

Attach sleeve of KM-J-23078-A (6) to hub of centre support (4)

and compress KM-J-23078-A using fastening nut (5), so that the

groove for the retaining ring of the spring set seat is free.

Install retaining ring in ring groove with suitable

screwdriver.

Relieve tension on KM-J-23078-A and detach. Remove KM-680-A.

|

|

|

Install new O-rings (2) in transmission casing.

Install KM-675 (1) in bore holes shown in transmission

casing.

Caution

Leave KM-675 installed until converter housing is fitted.

Assemble intermediate casing (3) and transmission casing

(4).

Caution

Carefully slide intermediate casing onto KM-675 so as not to

damage the gasket.

|

|

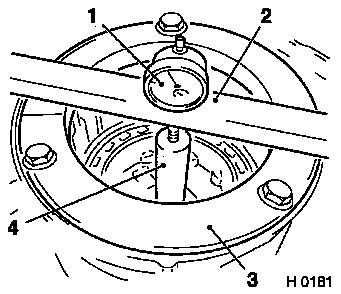

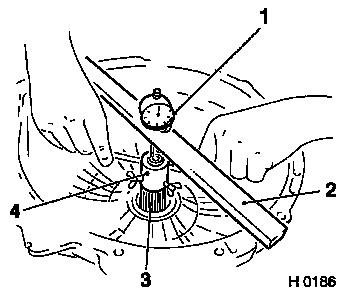

Measure

Measure

|

Measure axial play of drive shaft:

Slide KM-681-1 (3) over KM-675.

Attach KM-681-1 on intermediate casing with three fastening

bolts.

Position KM-681-2 (4) on drive shaft.

Position KM-238-2 (2) in conjunction with MKM-571-B (1) on

intermediate casing with corresponding pin as extension and set

dial gauge to "zero".

Manually load drive shaft axially at housing output in both

directions. Read off play from gauge.

Play must be between 0.36 mm (0.014") and 0.79 mm (0.031").

|

|

Assemble

Assemble

|

Install thrust washer (1) with guide tabs in corresponding

recesses in the clutch piston for 4th gear.

|

|

Caution

|

If thrust bearing (2) was removed, ensure it is properly seated

– note installation position.

Assemble

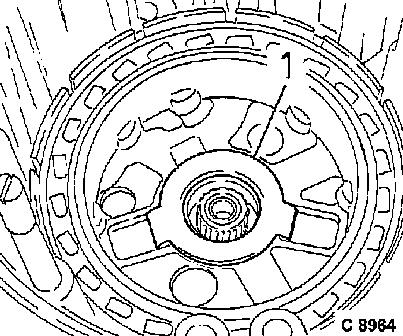

Assemble

Install hollow gear (1) and overrunning clutch assembly (3) in

the intermediate casing.

Install overrunning clutch assembly into intermediate housing by

turning slightly.

|

|

Caution

|

The lining plates must be laid in transmission fluid for about

20 minutes prior to installation.

Installation position of clutch discs and of thrust ring is

determined by guide lugs.

Assemble

Assemble

Alternately install steel plates (1) and lining plates in the

intermediate casing.

Insert thrust ring (2) with recess (3) outwards.

Attach KM-J-23085-A (4) to flange of intermediate casing.

Loosen locking screw and install inner shaft on clutch hub

contact surface.

Tighten locking screw and remove Measuring Gauge

KM-J-23085-A.

|

|

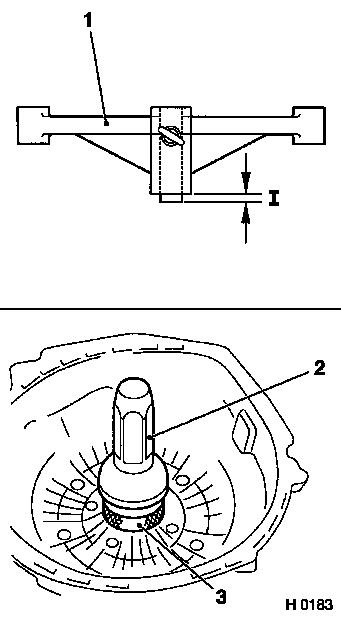

Measure

Measure

|

Remove dimension "I" (Illustration H

0183) at the measurement gauge (1) and select the relevant thrust

washer. The relevant thrust washers are available via the

"Aftersales" division.

|

Transmission end play (compensation by thrust washer)

|

|

Identifier for dimension "I" of measurement operations

|

|

old version

|

new version

|

|

yellow

|

-

|

|

red

|

1 lug (1.72/1.82 mm)

|

|

black

|

2 lugs (1.91/2.01 mm)

|

|

clear, white

|

3 lugs (2.10/2.20 mm)

|

|

green

|

4 lugs (2.29/2.39 mm)

|

|

blue

|

-

|

Do not exceed dimension "I" with the selected thrust washer,

i.e. preferably use next smaller sized washer.

Install

Install

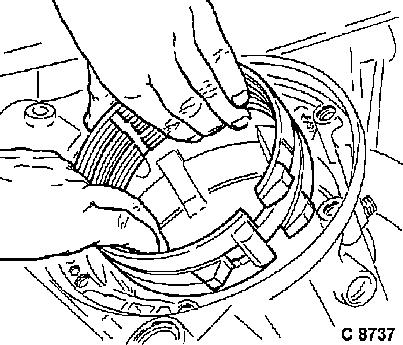

Install seal ring for the fluid pump in converter housing.

Attach KM-613-1 (3) and KM-J-28540 (2) and drive seal ring into

converter housing.

|

|

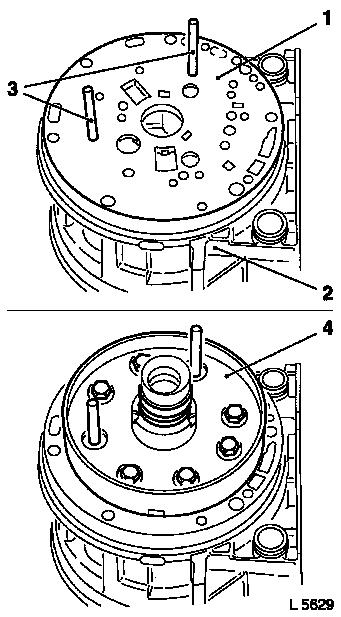

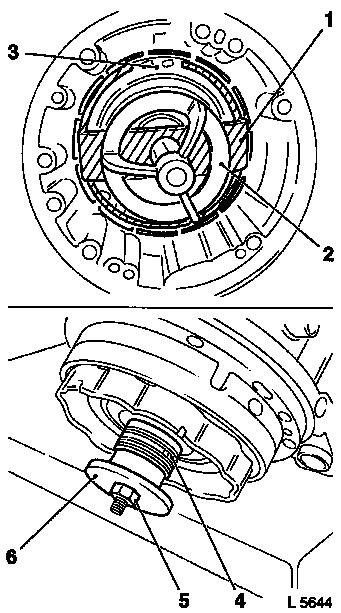

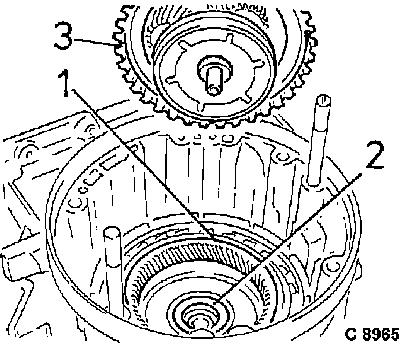

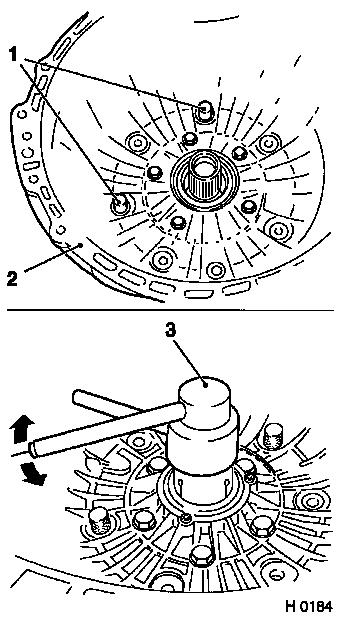

Assemble

Assemble

|

After installation, secure seal ring with three fastening bolts

(1).

|

|

|

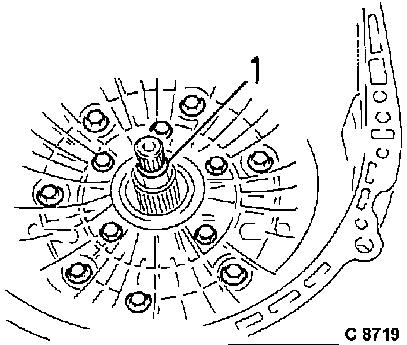

Install support plate (1) onto fluid pump.

Installation position of support plate (1) is determined by bore

holes (arrows).

|

|

|

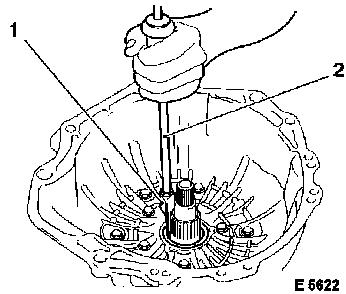

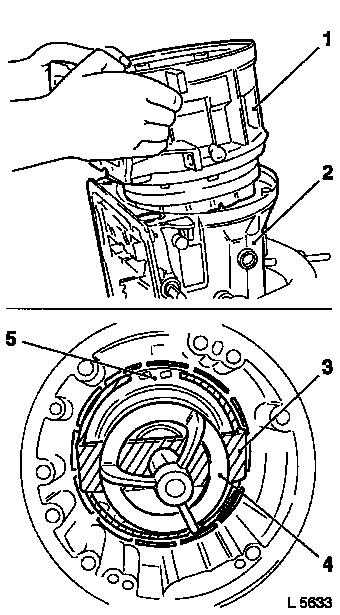

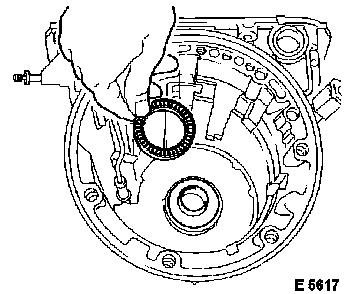

Place converter housing (2) on fluid pump. Installation position

of converter housing is determined by hole pattern of outer bolt

circle.

Insert KM-676 (1) into outer screw circle for locking. Install 5

fastening bolts of the inner screw circle and loosely tighten.

Fit KM-692 (3) up to stop on fluid pump shaft – outer part

fits into fluid pump seal ring.

Hold lower tommy bar, manually tighten upper tommy bar

(arrow).

This centralises the fluid pump with respect to the converter

housing.

Torque

Tighten 5 inner fastening bolts for fluid pump at converter

housing alternating crosswise – 20 Nm / 15 lbf. ft.

Release KM-692 at upper toggle and remove. Remove KM-676.

|

|

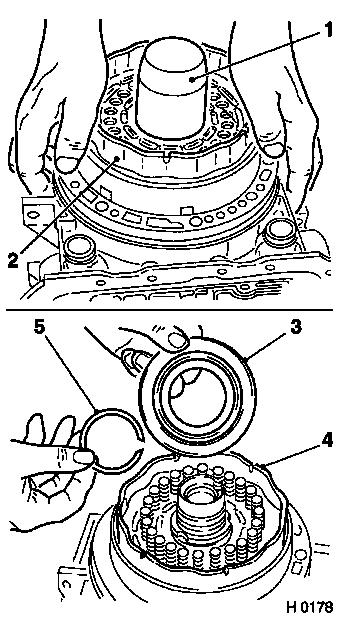

Assemble

Assemble

|

Coat selected thrust washer (1) with installation grease and

attach to fluid pump hub – note installation position.

Attach gasket (2) – installation position is determined by

the hole pattern.

Attach seal ring (3) to converter housing (arrow).

Caution

Avoid damaging the gasket with KM-675 (5).

Assemble

Assemble

Carefully attach converter housing (4) on intermediate casing

(6) with fluid pump installed.

|

|

|

Insert 5 fastening bolts on outer screw circle and tighten

slightly. Detach KM-675, insert remaining 2 fastening bolts and

tighten slightly.

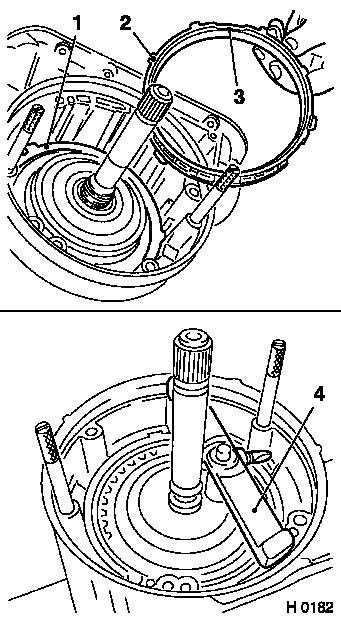

Measure

Measure

Measure final axial play: Slide KM-682 (4) onto drive shaft and

tighten locking bolt.

Position KM-238-2 (2) in conjunction with MKM-571-B (1) and

corresponding pin as extension on converter housing and place probe

of dial gauge on face of drive shaft.

Caution

Pull drive shaft (3) with KM-682 upwards until point of contact

is noticeable. Set dial gauge to "zero". Then continue to turn

drive shaft upwards and read off the play on the dial gauge. Play

must be between 0.10 mm (0.004") and 0.69 mm (0.027").

|

|

Remove Remove

|

Detach MKM-571-B, KM-238-2 and KM-682.

Assemble

Assemble

Install new O-ring (1) on drive shaft.

|

|

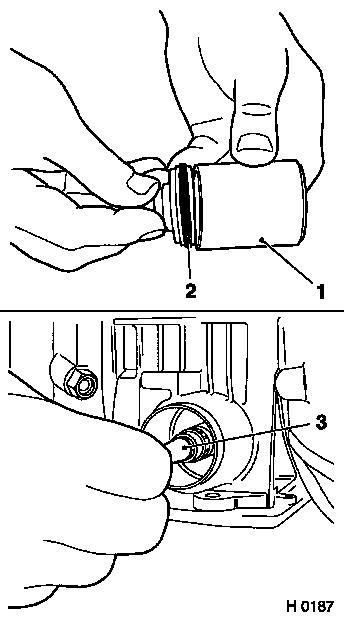

Assemble

Assemble

|

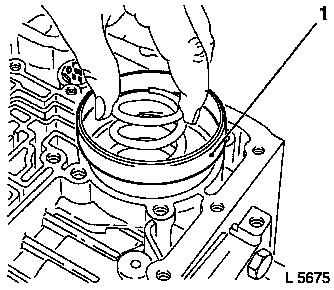

Replace O-ring (2) of 3/4 accumulator piston.

Slide 3/4 accumulator piston into KM-685 (1) to protect

O-ring.

To do this, coat O-ring with transmission fluid or installation

grease.

For further assembly, turn transmission in adapter by

90°.

Insert accumulator piston in conjunction with KM-685 into

transmission casing.

Install accumulator piston with suitable pipe (3).

Remove KM-685.

|

|

|

Insert pin (2) and spring (1).

Install new seal cap (3) for accumulator piston.

|

|

|

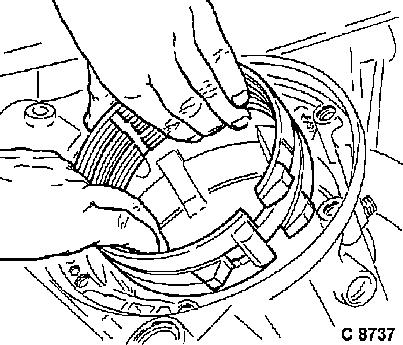

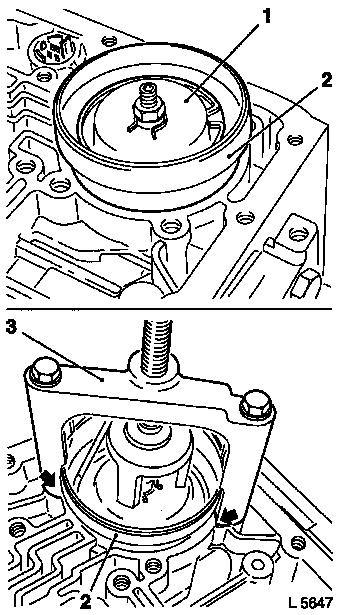

Attach KM-686-1 (2) to the intermediate casing. The short side

of bridge points to the converter housing. Compress accumulator

spring with KM-469-14 (3) until the ring groove is free. Install

retaining ring (1). Ensure correct seating – press into ring

groove with screwdriver if necessary. Relieve tension on KM-686-1

and detach with KM-469-14 (3).

|

|

Caution

|

Before further assembly, turn transmission in adapter by

90°.

Assemble

Assemble

Fit fluid reservoir (3) in the transmission casing. Installation

position is determined by the guide (2). Insert vent pipe (1) in

bore in transmission casing and fluid reservoir.

Slide parking lock gear (5) onto output shaft.

Install pulse pickup (6) of output speed sensor onto output

shaft.

Attach new gasket (4) onto transmission casing.

|

|

Inspect

Inspect

|

Check seal ring (2), radial needle bearing (1) and liner (3) in

the extension for damage and wear, replace with new parts if

necessary.

Only required when replacing: Remove seal ring using KM-J-7004

in conjunction with KM-586.

Assemble

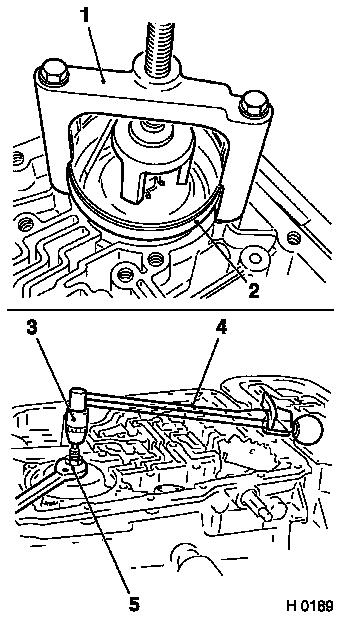

Assemble

Install retaining spring (5) with angled end towards pawl and

pawl (4) for parking lock gear in transmission extension.

|

|

Caution

|

Actuation rod (2) for parking lock must slide in the liner.

Assemble

Assemble

Position transmission extension (1) onto transmission

casing.

If fitted – attach bracket for wiring harnesses (3, 4 and

5) with fastening bolts (arrows) crosswise.

Torque

Transmission nose piece to transmission housing – 32 Nm /

23.5 lbf. ft.

|

|

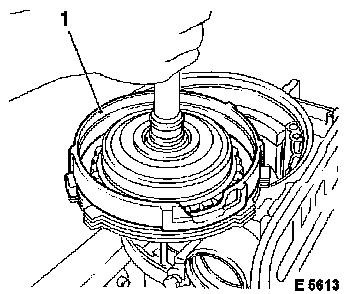

Assemble

Assemble

|

Install new seal ring with KM-629-1 (1) in transmission

extension.

|

|

|

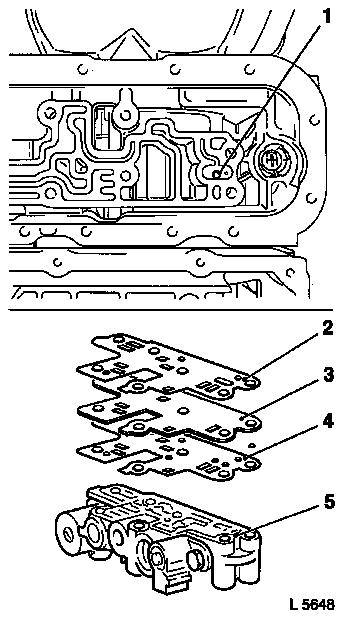

Insert valve ball (1) into the fluid duct of the intermediate

casing. Secure with installation grease.

Caution

The installation sequence must be observed. Gasket (2) is

provided with a slot. Gasket (4) is provided with 2 bores at the

corresponding location.

Assemble

Assemble

Place gasket (2), support plate (3) and gasket (4) onto valve

body (5) of intermediate casing.

|

|

|

Place valve body assembly with gaskets and support plate (1)

onto intermediate casing. Insert 7 fastening bolts.

Torque

Valve body to intermediate housing – 20 Nm / 15 lbf.

ft.

|

|

|

Route wiring harness at the plug connection for pressure

regulator solenoid valve (1) under the retaining lug (2).

Connect wiring harness plug to pressure regulator solenoid

valves (1) and converter clutch (3).

Insert connecting plug into intermediate housing (5).

Restore plug connection (4 and 5) on the intermediate

casing.

|

|

|

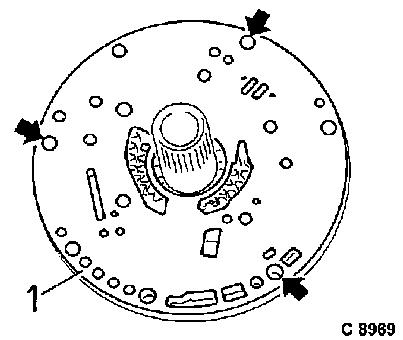

Insert 2 valve balls into fluid ducts (arrows) of transmission

housing.

Caution

Use installation grease for fixing.

Assemble

Assemble

Attach KM-678 (2) to transmission casing.

Put gasket (1) onto transmission housing.

|

|

|

Place valve body (1) over KM-678 (2) onto transmission

casing.

Caution

Long end of control lever points towards shift valve.

Assemble

Assemble

Attach shift valve (5) with control lever (3) in valve body

assembly.

Attach control lever to shift segment (4).

|

|

|

Attach 7 fastening bolts (arrows) – tightening torque 20

Nm / 15 lbf. ft.

Detach KM-678 (1 and 2).

Insert main housing connection plug – insert new

additional support O-ring in dedicated groove.

Insert 7-pin wiring harness plug (4) at connection plug on

transmission. Route wiring harness for solenoid valves correctly

through indentations of the valve body to prevent damage when

bolting on fluid screen.

Attach detent spring (3) to transmission with fastening bolts

(arrows) – tightening torque 20 Nm / 15 lbf. ft.

|

|

|

Place wiring harness (2) on valve body assembly (4).

Attach wiring harness plug to solenoid valve for 1/2 and 3/4

shift (5).

Attach wiring harness plug to solenoid valve for 2/3 shift

(1).

Attach wiring harness plug to brake band servo solenoid valve

(3).

|

|

|

Attach brake band servo cover (1) with new gasket (4 fastening

bolts) – tightening torque 25 Nm / 18 lbf. ft.

Attach fluid screen (3) with stuck-on gasket (2) to valve body

assembly (3 fastening bolts) – tightening torque 20 Nm / 15

lbf. ft.

|

|

Caution

|

Insert fastening bolts with locking compound, if not

microencapsulated.

Torque

Attach fluid pan (1) with gasket (2) to intermediate casing (3)

(12 fastening bolts) – tightening torque 12 Nm / 9 lbf.

ft.

Caution

Insert fastening bolts with locking compound, if not

microencapsulated.

Torque

Attach fluid pan (4) with gasket (5) and fixing magnet (7) on

transmission casing (6) (16 fastening bolts) – tightening

torque 12 Nm / 9 lbf. ft.

|

|

Assemble

Assemble

|

Attach output speed sensor to transmission extension (1

fastening bolt and washer) – tightening torque 12 Nm / 9 lbf.

ft.

|

|

|

Push selector lever position switch with wiring harness (1) onto

transmission selector lever shaft (2) and screw in 2 fastening

bolts – only tighten after the adjustment.

Adjust Adjust

Adjust selector lever position switch – see corresponding

operation in this group.

|

|

Assemble

Assemble

|

Apply locking compound to the thread of the output shaft.

Attach output flange (2) to output shaft with fastening nut

– tightening torque 100 Nm / 74 lbf. ft.

Note: Use socket A/F

30, extra long and KM-623 (1) to counterhold.

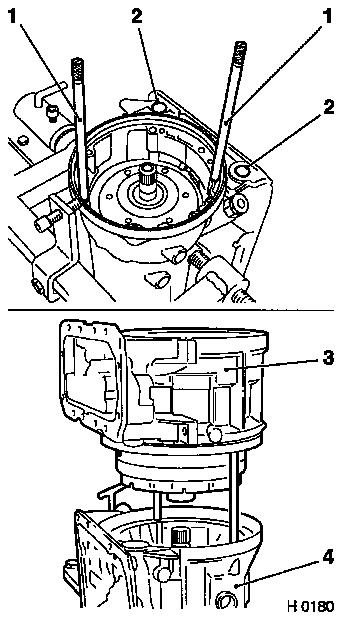

Assemble

Assemble

Attach torque converter with KM-574 (3) to drive shaft.

Remove KM-574.

|

|

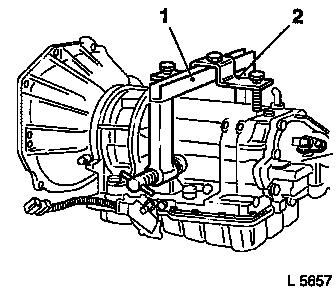

Remove Remove

|

Detach transmission with KM-113-A (1) and KM-113-5 (2) from

KM-113-2.

Detach KM-113-A and KM-113-5.

Install

Install

"Automatic Transmission, Remove and Install (Vehicles with

4-Cylinder Petrol Engine)", "Automatic Transmission, Remove and

Install (Vehicles with V6 Engine)", "Automatic Transmission, Remove

and Install (Vehicles with Diesel Engine)".

|

|

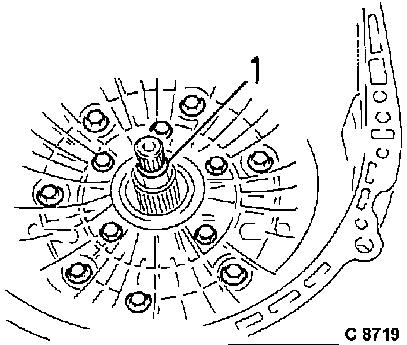

|