|

Manual Transmission from Engine, Detach and

Reattach

|

Remove Remove

Remove engine – see operation "Engine, Remove and

Install".

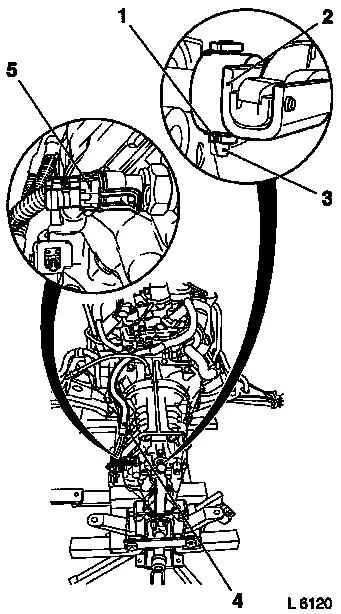

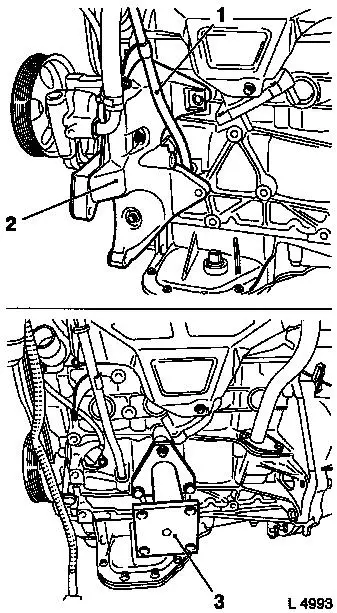

Remove retaining clip (1) and pull out retaining pin (3) upwards

– remove shift rod (2).

Disconnect wiring harness plug (5) from reversing lamps switch

and expose cable bundle (4). Lay cable bundle aside.

|

|

|

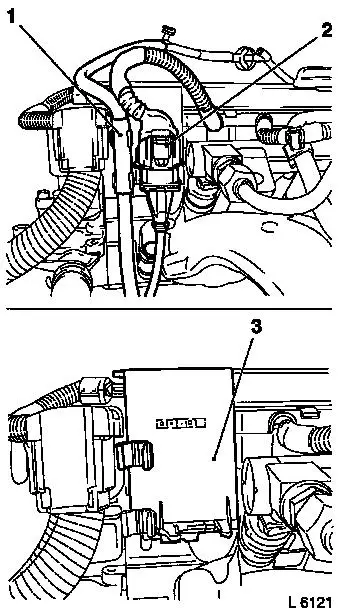

Unclip vacuum line (1) with wiring harness plug for knock sensor

(2) from bracket (3). Detach bracket from engine transport

shackle.

|

|

|

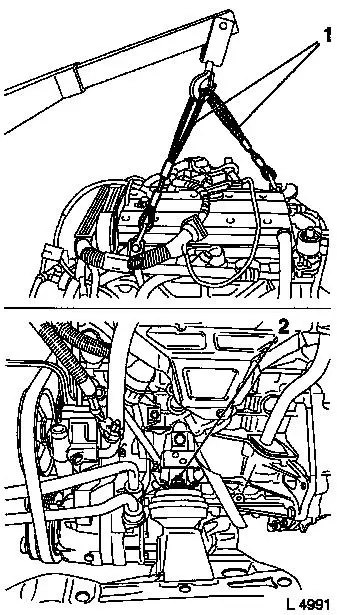

Attach Retaining Cables KM-2358 (1) to engine transport

shackles. Suspend retaining cables from workshop crane and lift

workshop crane until retaining cables are taut.

Remove engine damping block fastening nuts (2) right and left of

engine bracket.

Lift engine with transmission off front axle body and place

carefully on a suitable surface.

|

|

|

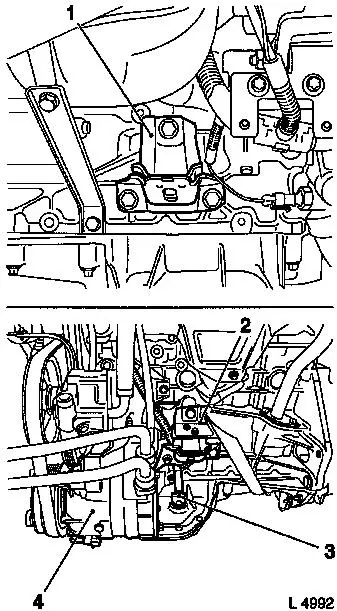

Remove right (1) and left (2) engine damping block brackets from

cylinder block.

Disconnect wiring harness plug (3) from dynamic oil level

control sensor.

Remove wiring harness from auxiliary units support.

Remove ribbed V-belt – see operation "Ribbed V-belt,

Remove and Install".

Remove compressor (4) with refrigerant lines from auxiliary

units support.

|

|

|

Remove oil dipstick guide tube (1) from auxiliary units

support.

Remove auxiliary units support (2) from cylinder block.

Attach KM-412-8-A (3) to cylinder block right and left.

Attach engine to KM-412.

Remove rear transmission holder.

|

|

|

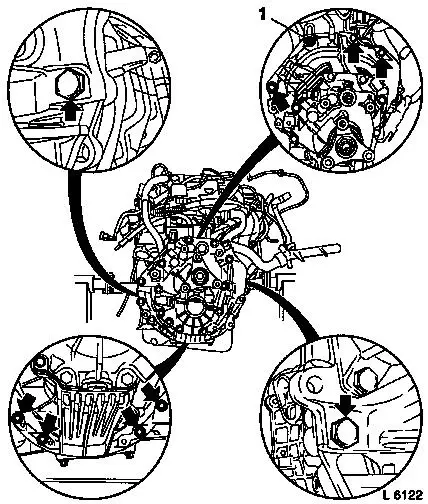

Remove transmission fastening bolts (arrows).

Suspend transmission on workshop crane.

Remove last transmission fastening bolt (1).

Remove transmission from engine.

Install

Install

Attach transmission to cylinder block.

Tightening torque (M8) 20 Nm / 15 lbf. ft.

Tightening torque M10: 60 Nm / 44 lbf. ft.

Detach transmission from workshop crane.

|

|

Remove rear transmission holder.

Attach engine with Retaining Cables KM-2358 to workshop crane

and remove from KM-412. Carefully lower on suitable support.

Remove KM-412-8-A from cylinder block right and left.

Connect auxiliary component main bracket to cylinder block

– tightening torque 35 Nm / 25.8 lbf. ft.

Install oil dipstick guide tube to auxiliary units support

– tightening torque 25 Nm / 18.5 lbf. ft.

Attach compressor with refrigerant lines to auxiliary units

support – tightening torque 35 Nm / 26 lbf. ft.

Install ribbed V-belt – see operation "Ribbed V-belt,

Remove and Install".

Attach wiring harness to auxiliary units support. Attach wiring

harness plug to dynamic oil level control sensor.

Attach right and left engine damping block bracket to cylinder

block – 60 Nm / 44.5 lbf. ft.

Lift engine with transmission and carefully insert into front

axle body. Attach engine bracket to engine damping blocks with

fastening nuts – tightening torque 40 Nm / 30 lbf. ft.

Remove Remove

Remove Retaining Cables KM-2385 from engine transport

shackle.

Install

Install

Place bracket on engine transport shackle and clip in vacuum

line with wiring harness plug for knock sensor.

Route wiring harness at transmission and connect wiring harness

plug to reversing lamps switch.

Attach shift rod with retaining pin and secure with retaining

clip.

Install engine – see operation "Engine, Remove and

Install".

|