|

Windscreen, Remove and Install

Remove Remove

|

|

Bonnet - see operation "Bonnet, Bonnet Functioning Parts, Remove

and Install" in group "A". Water deflector - see operation "Water

Deflector, Remove and Install" in group "A".

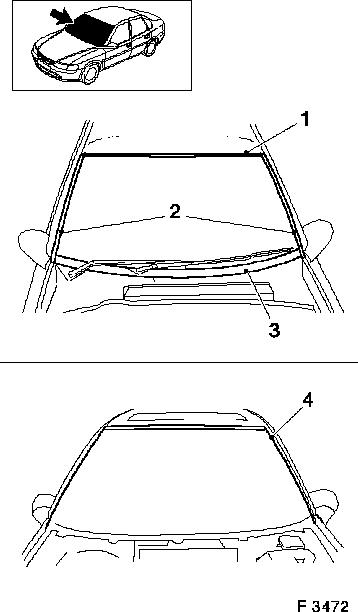

Upper A-pillar inner panelling

Upper screen trim strip (1), side screen trim strip (2), lower

screen trim strip (3).

Inside rear view mirror.

Caution

To avoid damage to paintwork, mask off windscreen frame in the

cutting area of the A-pillar and on the roof frame with standard

commercial textile adhesive tape (4).

|

|

|

|

Note: The following

are used for removing the windscreen:

|

Swinging Blade

|

MKM-846-1E (electric)

|

|

Swinging Blade

|

MKM-846-1P (pneumatic)

|

|

Wire Cutter

|

MKM-589-B with protective hose

|

Operations using Wire Cutter MKM-589-B are not described.

All 3 cutting tools can be used to remove the glass from the

windscreen.

|

|

Remove Remove

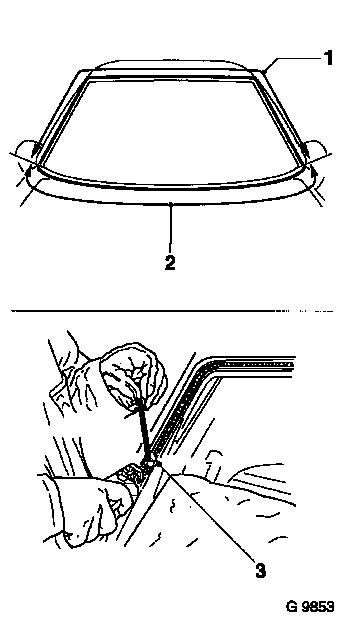

Remove windscreen from the outside using Swinging Blade

MKM-846-21 in areas (1) and (2):

Note: Do not damage

the moulded headlining when removing the windscreen.

Cutting blade must not touch the edge of the glass during

cutting!

Immediately before installation, cut back residue of bead of

adhesive on windscreen frame with MKM-846-70 to a thickness of

approx. 1 mm (3). Activate residual bead with activator.

If necessary, rectify paint damage on windscreen frame

properly.

Install

Install

|

|

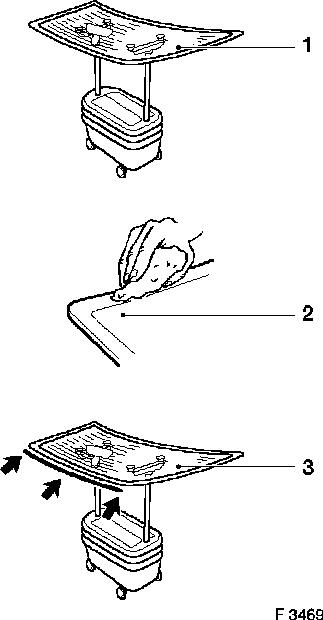

Windscreen on holder (1),

Clean area to be bonded (2).

If re-using windscreen:

Immediately before installing the windscreen, cut back residue

of bead of adhesive on windscreen to a thickness of 1 mm with

standard commercial scraper or with MKM-846-70.

Remove masking tape from windscreen frame without leaving any

residue. Insert trim strip, windscreen top, (3) into windscreen

(arrows). Apply glass cement.

Note: Apply adhesive

to residual bead on windscreen. Use pre-cut applicator nozzle from

adhesive set. Never apply primer to the residual adhesive bead (no

adhesion). After applying the glass cement, insert windscreen

immediately, press gently into the adhesive bed and secure. Minimum

height of glass cement after securing is 4 mm.

|

|

Install

Install

|

|

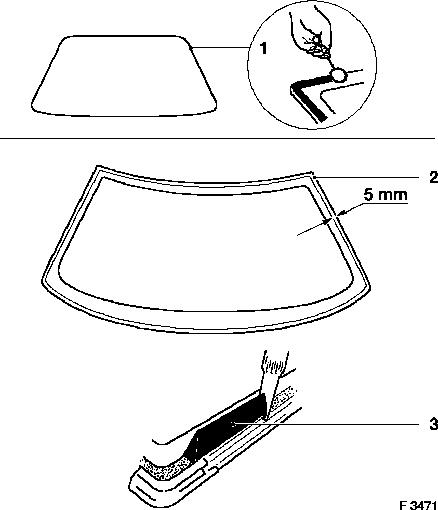

For new windscreens:

Clean/activate area of windscreen to be bonded and then wipe

dry, Insert trim strip at the top of the windscreen. Apply black

glass primer parallel to the edge of the windscreen (1) - allow to

dry for 15 minutes.

Apply glass cement (3).

- Top - below windscreen trim strip (2).

- At the sides and the bottom - approx. 5 mm from the edge of the

windscreen.

Use pre-cut applicator nozzle from adhesive set.

After applying the glass cement, insert screen immediately,

press gently into the adhesive bed and secure. Minimum height of

glass cement after securing is 4 mm.

|

|

Install

Install

|

|

Insert windscreen with Suction Lifter MKM-641 in screen.

Note: A second

mechanic is required when inserting the windscreen.

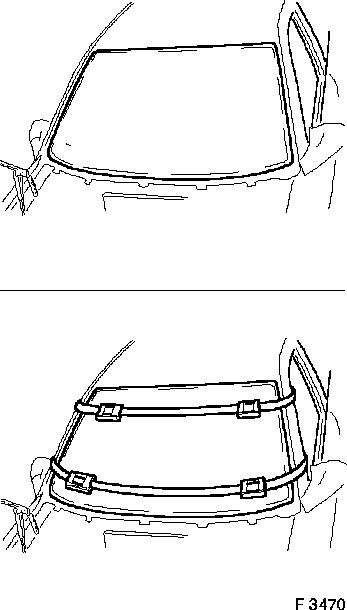

Install

Install

Fix windscreen in place with Tension Belts MKM-591.

|

|

Caution

The front doors must not be opened when the belts are under

tension.

Install

Install

Side screen trim strip, lower screen trim strip.

Water deflector

Inside rear view mirror.

Bonnet, upper A-pillar inner panelling

Note: Adjustment of

wiper arms - see operation "Windscreen Wiper Motor, Remove and

Install" in group "N".

Caution

For lay-over times of recently adhered glass panes in

conjunction with glass cement and airbag equipment – see

operation "Lay-over Times for Vehicles". Note processing

instructions from adhesive manufacturer and on the packaging.

|