|

Removing and installing parts of lubrication system

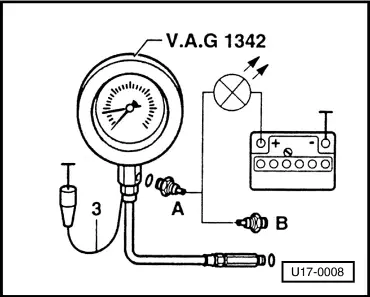

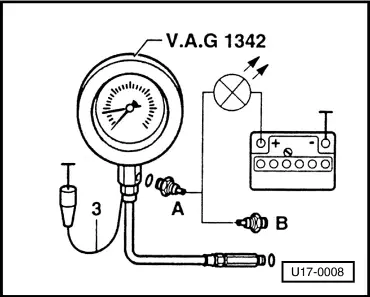

Checking oil pressure and oil pressure switch

Special tools, testers and auxiliary items

-

◆ Oil pressure tester V.A.G 1342.

-

◆ Diode test V.A.G 1527.

-

◆ Adapter set V.A.G 1594.

Note:

Functional check and servicing the optical and acoustic oil pressure warning:

=> Current flow diagrams, Electrical fault finding and Fitting locations

|