Golf Mk1

|

Repairing clutch controls

Repairing clutch

|

|

|

|

Note: Remove gearbox beforehand. When removing and installing the clutch following should be noted: Clean the splines on drive shaft and, with used clutch plate the splines in the hub, remove corrosion and apply a thin coat of grease G 000 100 to the drive shaft. Then move plate to and fro on the shaft until the hub moves freely on the shaft. Surplus grease must be removed. TDC sensor adapter in clutch housing . Caution

Assemble clutch so that the centering pins in flywheel engage the centering holes or slots in the pressure plate. Otherwise the TDC mark on flywheel will no longer be correct. |

|

|

|

|

|

|

|

|

|

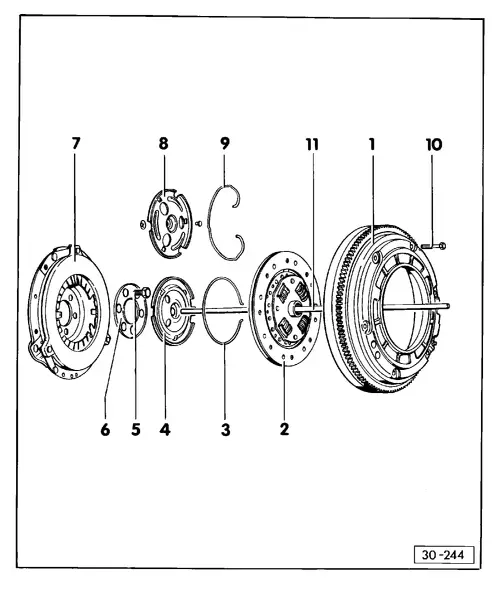

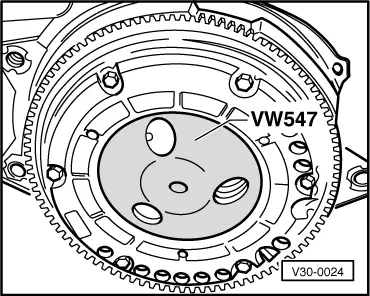

Fig.1 Removing and installing flywheel |

|

|

|

Fig.2 Installing clutch plate

|

|

|

|

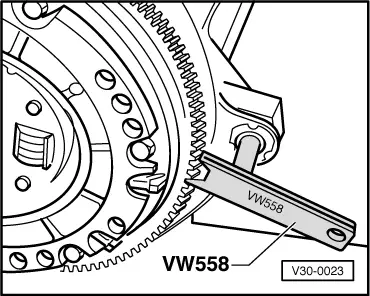

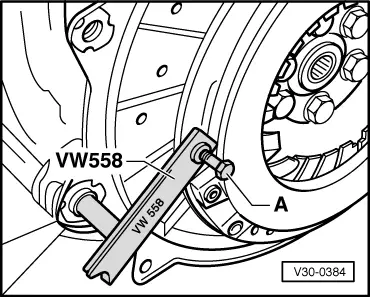

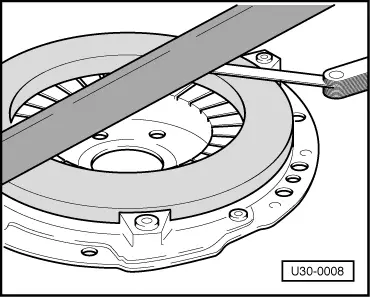

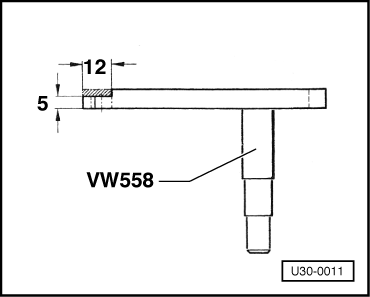

Fig.3 Removing and installing pressure plate Note: To fit the 200 mm clutch the retainer VW 558 must be reworked as shown in fig. 9. |

|

|

|

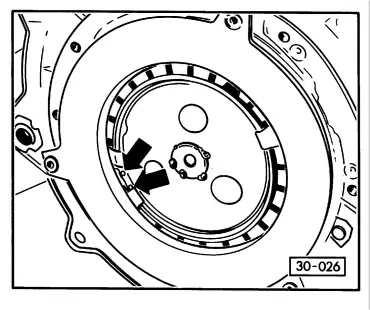

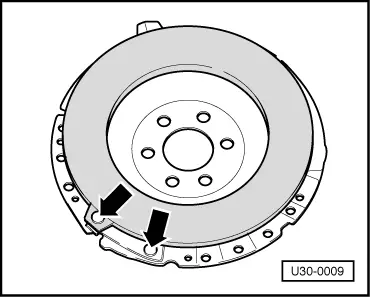

Fig.4 Installing retaining ring (190 mm clutch) Watch position of ring ends |

|

|

|

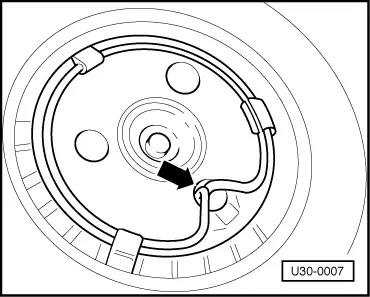

Fig.5 Installing retaining ring (200 mm clutch) Watch position of ring ends. |

|

|

|

Fig.6 Checking pressure plate for distortion, cracks and signs of burning Maximum inward taper 0.2 mm. |

|

|

|

Fig.7 Check spring connections between pressure plate and cover for cracks, loose rivets and security Clutches with damaged or loose rivets should be renewed. |

|

|

|

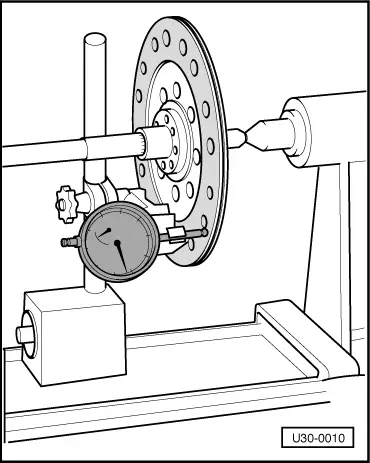

Fig.8 Checking clutch plate for lateral run-out Max. 0.3 mm (Measured 2.5 mm from outer edge) |

|

|

|

Fig.9 Reworking retainer VW 558 The shaded area must be reworked to dimensions given. Note: The 200 dia. clutch can be service installed by replacing the pressure plate, flywheel , clutch plate, release plate and retaining ring. |