Golf Mk1

|

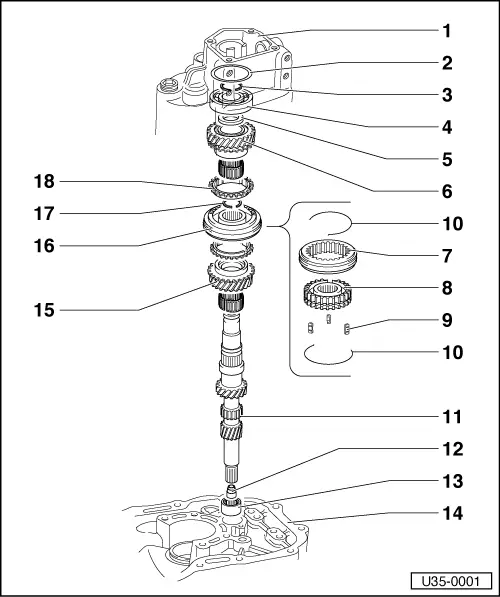

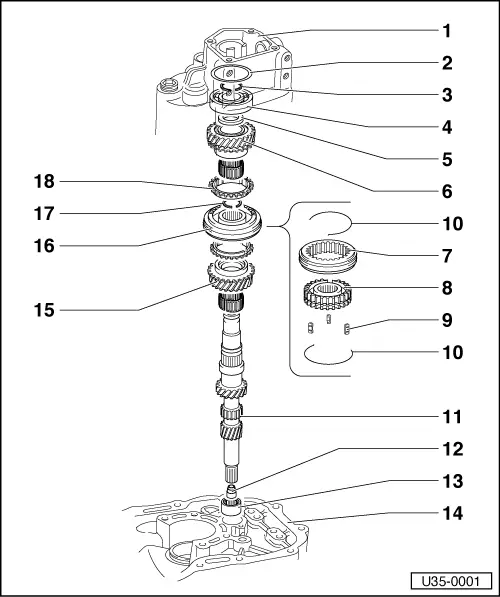

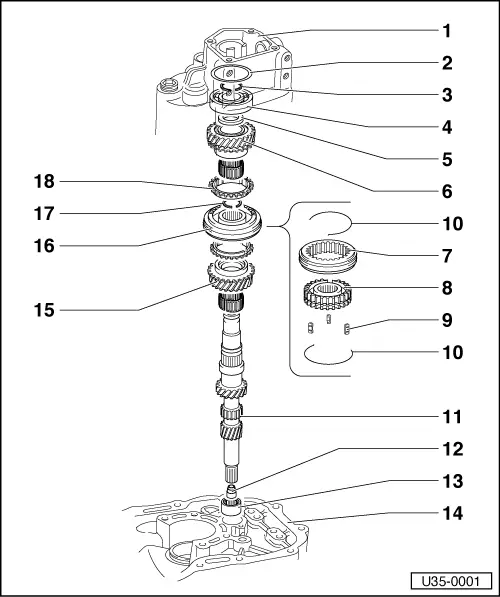

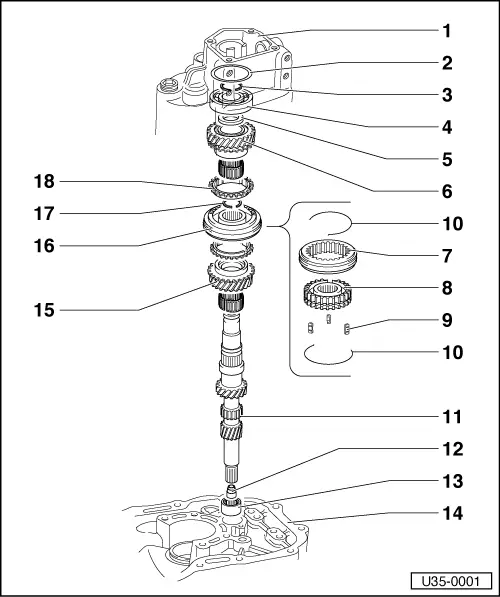

Dismantling and assembling input shaft

Dismantling and assembling input shaft

|

|

|

|

Note: When installing new gears, see Technical Data =>page 00-3 |

|

|

|

|

|

|

|

|

|

|

|

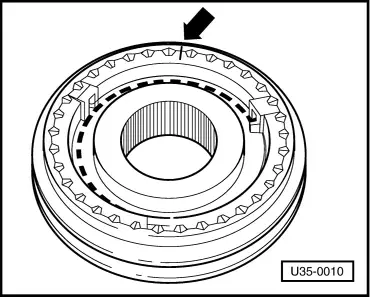

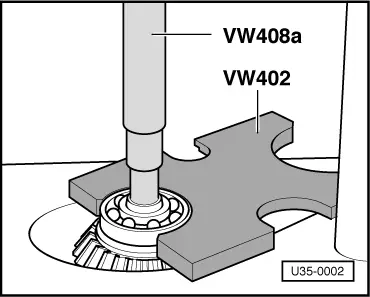

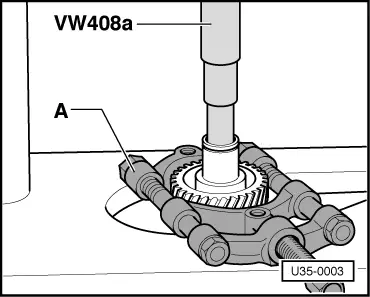

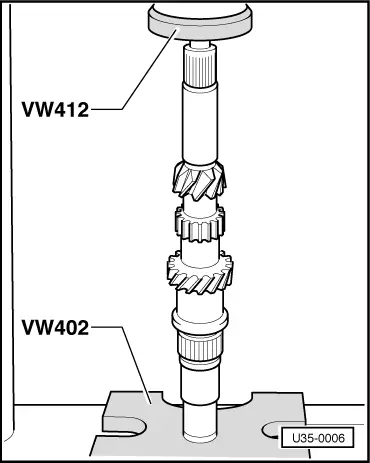

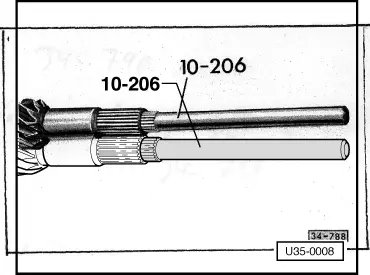

→ Fig.1 Pressing ball bearing off |

|

|

|

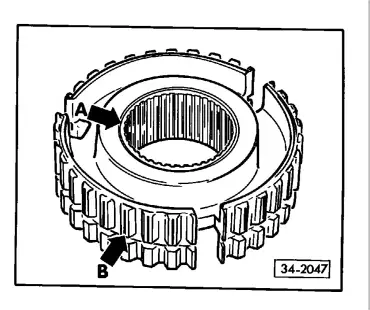

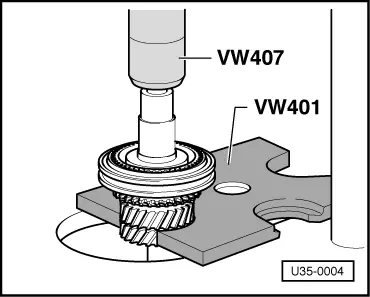

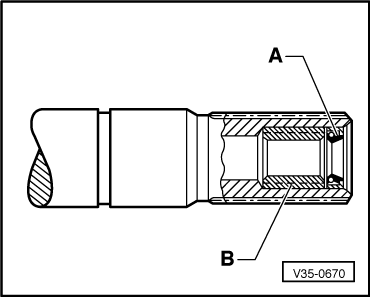

→ Fig.2 Pressing 4th speed gear and thrust washer off A - Separating appliance

|

|

|

|

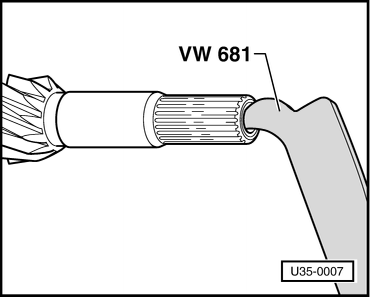

→ Fig.3 Pressing off sleeve/hub with 3rd speed gear |

|

|

|

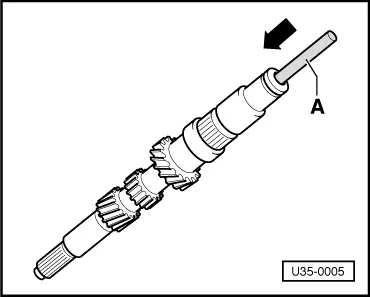

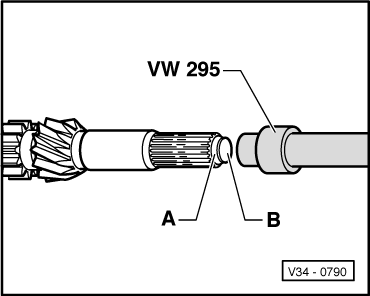

→ Fig.4 Knocking out bush and seal for clutch push rod A = 10 mm such as an old pump shaft from automatic box. |

|

|||||||||

|

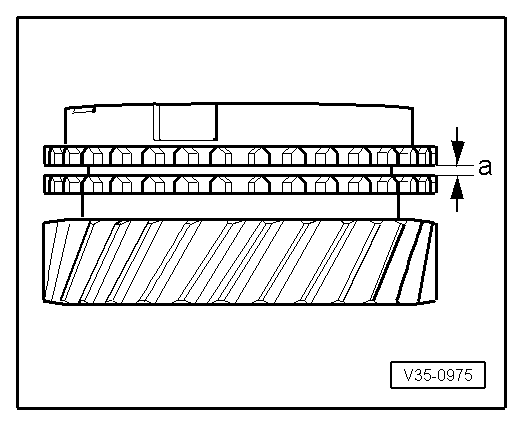

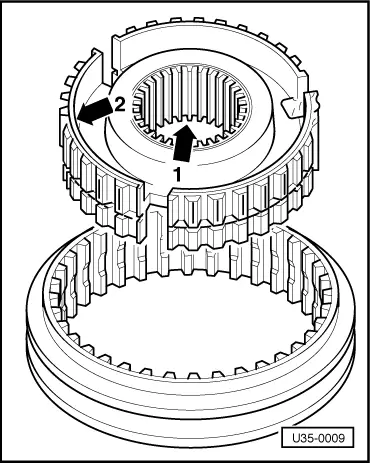

→ Fig.5 Checking synchronizer rings

|

|

|

|

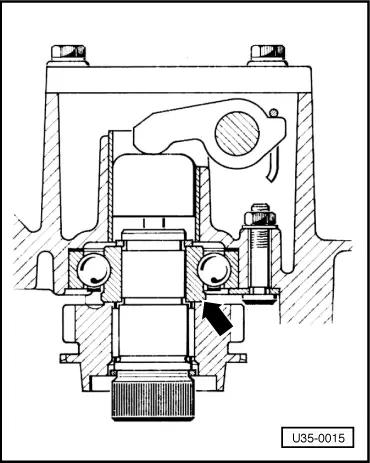

→ Fig.6 Pressing in bush and seal for clutch push rod (must be flush) Mod: |

|

||||

|

From 27 10 7 → Fig.7 Position of seal and bush

Note: The new seal and bush can be installed in gearboxes before Assy. date 27 10 7. |

|

|

|

→ Fig.8 Pulling seal for clutch push rod out |

|

|

|

→ Fig.9 Installing seal

|

|

|

|

→ Fig.10 Drive bush in fully |

|

|

|

→ Fig.11 Assembling sleeve and hub for 3rd/4th gear Position:

|

|

|

|

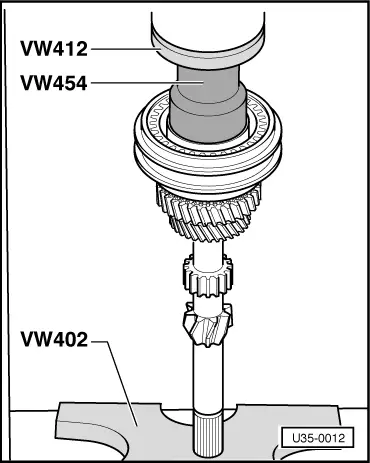

→ Fig.14 Pressing hub and sleeve on Fitting direction =>Fig. 11

|

|

|

|

→ Fig.15 Pressing thrust washer on Only up to 18 06 5 |

|

|

|

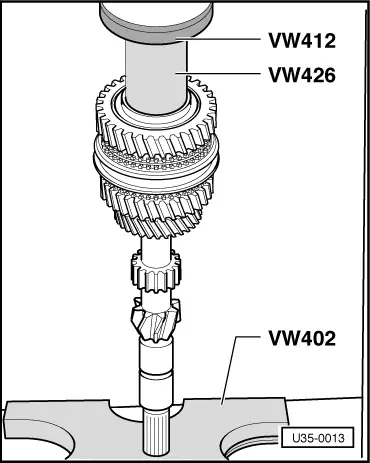

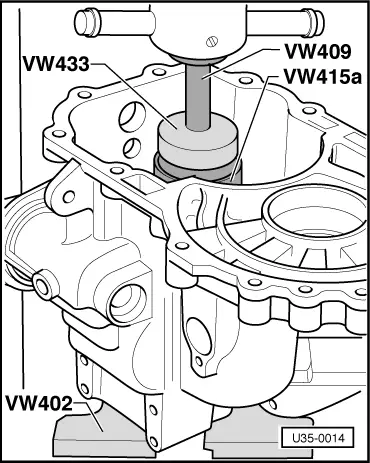

→ Fig.16 Pressing ball bearing and shim into the gearbox housing Modification From gearbox 19 06 5 |

|

|

|

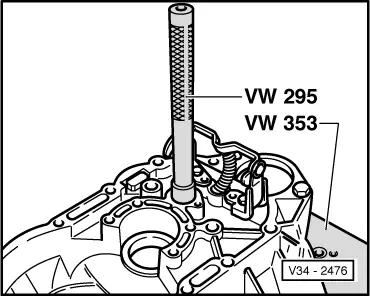

→ Fig.18 Pulling drive shaft needle bearing out

|

|

|

|

→ Fig.19 Knocking in drive shaft needle bearing |