Golf Mk1

|

|

|

See also "Adjustment table"

Caution!

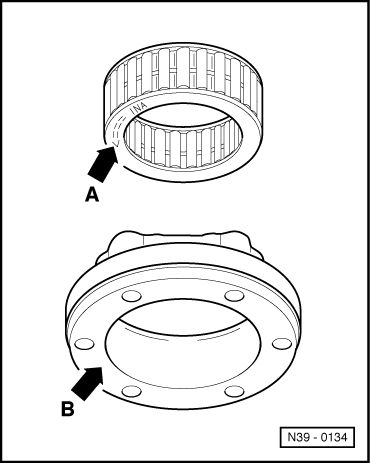

The inner and outer races of the taper roller bearings are matched. Do not interchange.

|

|

||||||||||||||||||||||

The following shims are available:

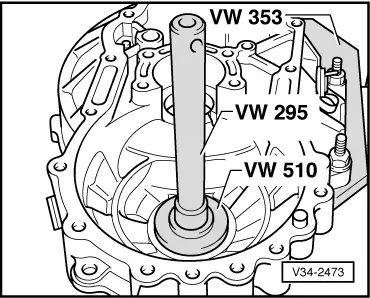

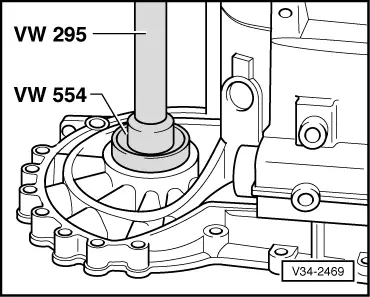

Different tolerances make it possible to select exactly the required shim thickness. Knock outer race in again and install gearbox housing complete with gasket. | ||||||||||||||||||||||

|

|

|

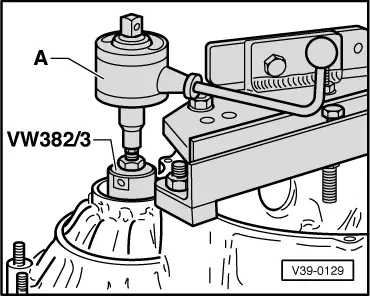

→ A - Torque gauge, normal type 0 - 600 Ncm Checking turning torque This should be 120-350 Ncm for new bearings. On bearings which have been in use the torque should be at least 30 Ncm. Lubricate bearings beforehand with hypoid gear oil. |