Golf Mk1

|

Servicing valve gear

Servicing valve gear

|

|

|

|

Note: Cylinder heads with cracks between valve seats or between a valve seat insert and spark plug thread can continue to be used without reducing service life when these are surface cracks with a maximum width of 5.0, or when only outer threads of the spark plug socket are damaged.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

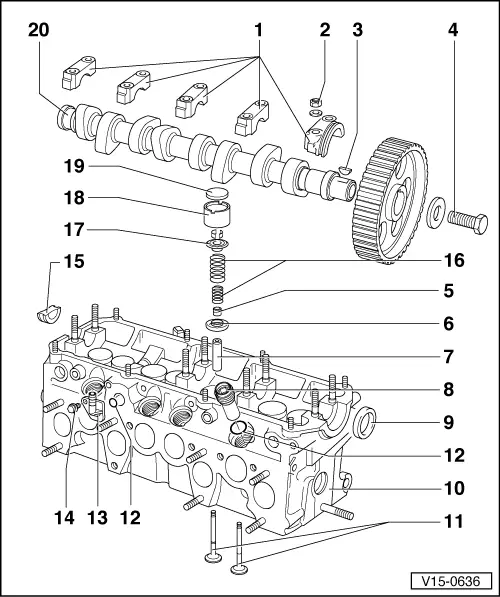

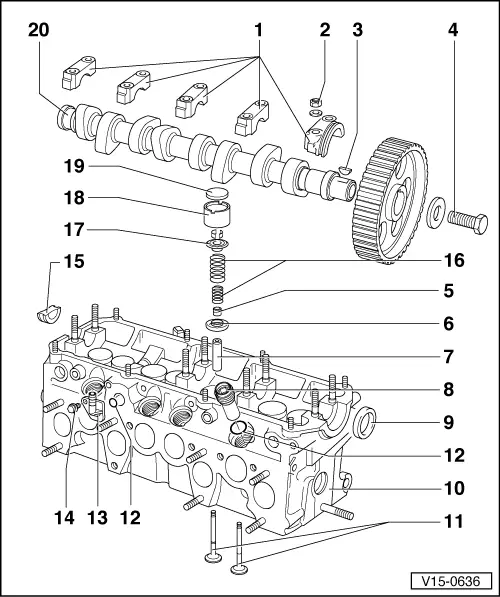

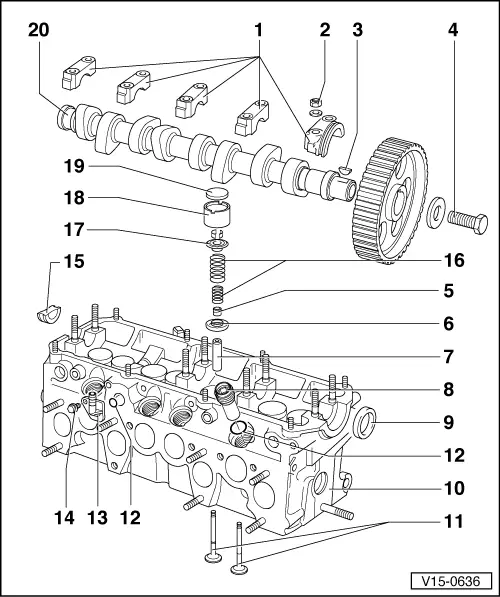

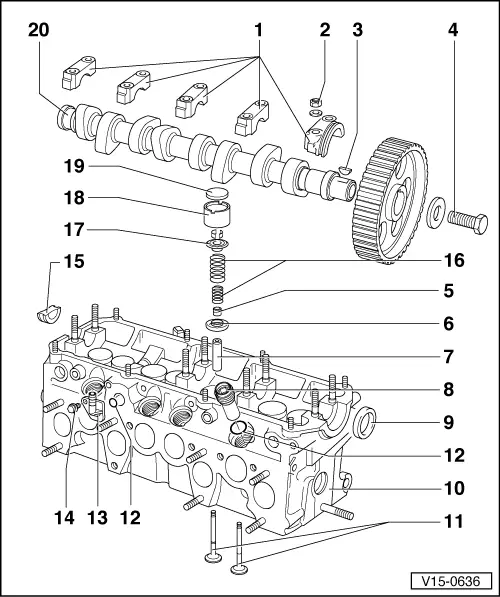

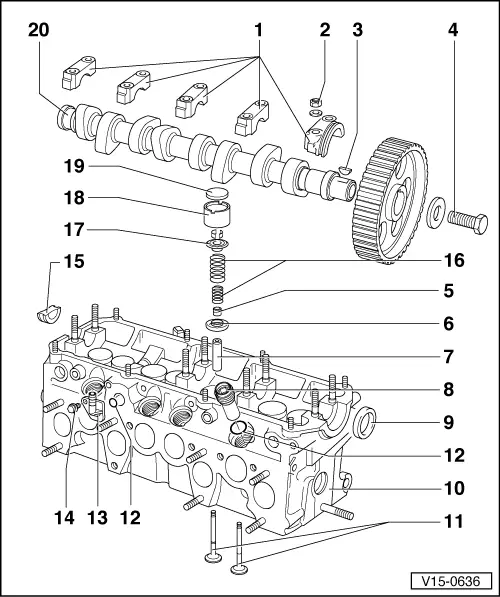

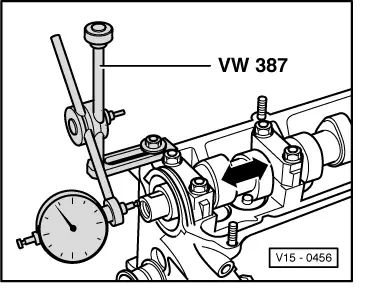

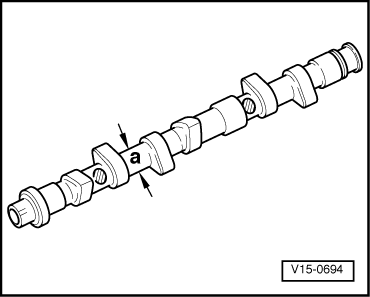

→ Fig.1 Camshaft, checking axial clearance Wear limit: 0.15 mm Check clearance with bucket tappets removed and bearings caps 1 and 5 installed. |

|

|

|

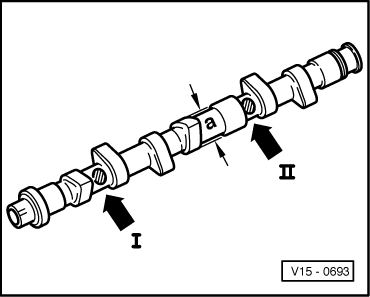

→ Fig.2 Position of camshaft bearing shells Watch bore offset. Before installing camshaft, place bearing caps in position to determine correct installation position |

|

|

|

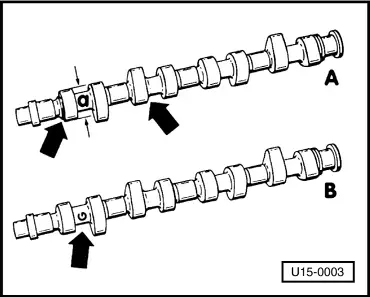

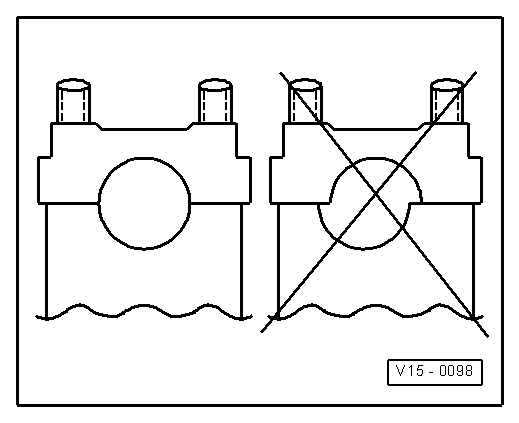

→ Fig.5 Replacement cylinder heads with camshaft bearing shells for the camshaft In some cases replacement cylinder heads and replacement engines are suplied with bearing shells for the camshaft. A - Cylinder head with normal-sized camshaft B - Cylinder head with undersized camshaft |

|

|

|

Note: The undersized camshaft is not supplied as a replacement part. When necessary, use normal camshaft with suitable bearing shells. → Fig.6 Cylinder head - reworking dimension Minimum height: a = 132.6 mm |

|

|

|

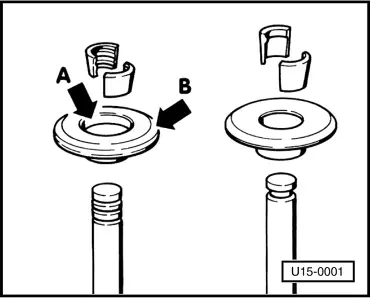

→ Fig.7 Valve versions Engine Code EG: Engine Codes DX, JH, JJ, KT, 2H: Ensure that correct cotters and upper spring seats are installed. Identification of upper spring seats for three-groove vale:

|

|

||||||||||||||||||||||||||||||||||||||||||||||||

|

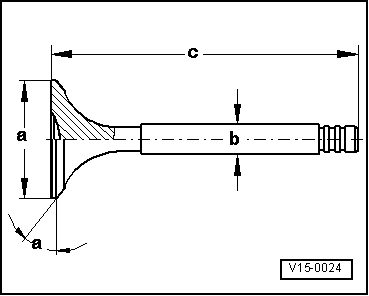

→ Fig.8 Valve dimensions

Important!

Valves are not to be machined. Only grinding - in by hand is permissible. | ||||||||||||||||||||||||||||||||||||||||||||||||