Golf Mk3

|

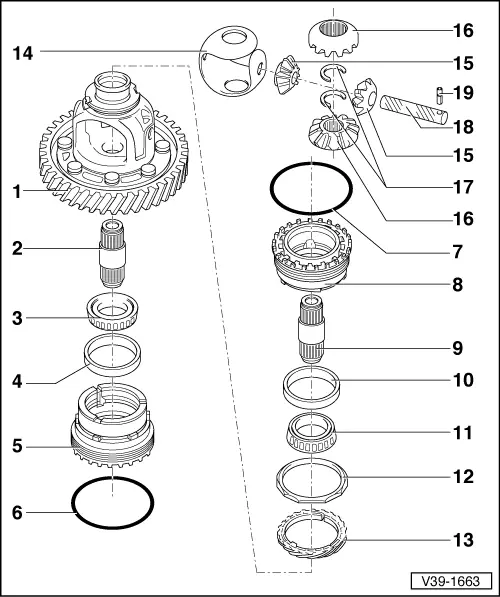

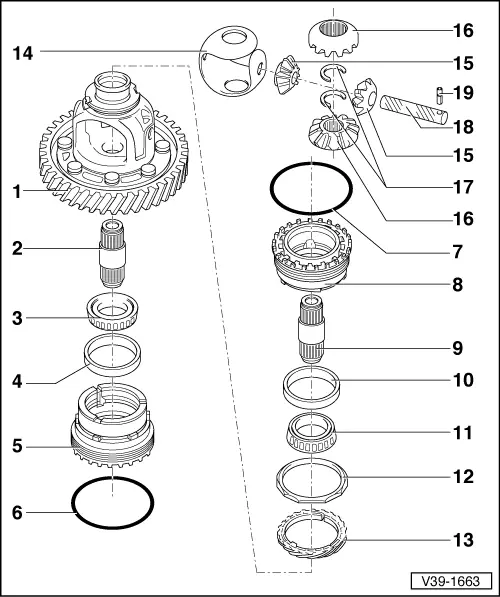

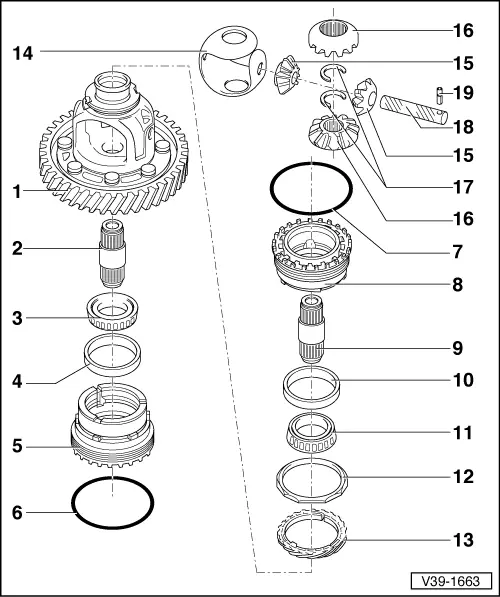

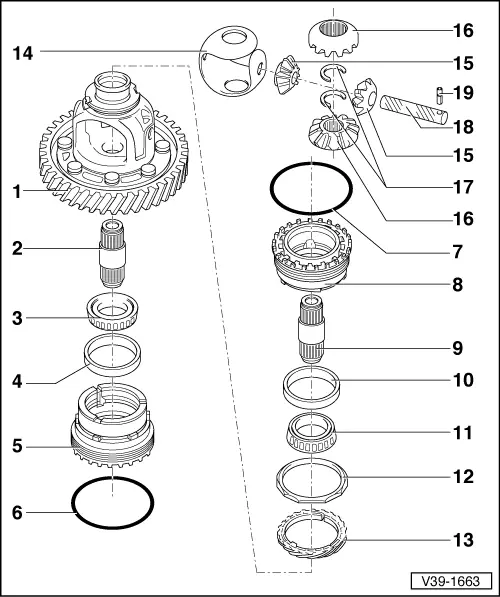

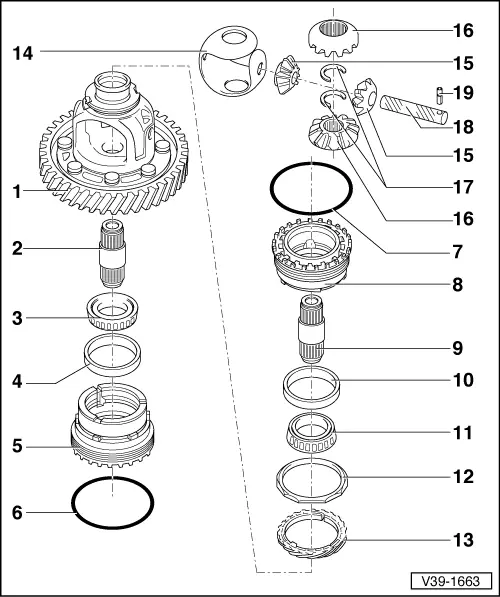

Dismantling and assembling final drive

Dismantling and assembling differential

|

|

|

|

Notes:

|

|

|

|

|

|

|

|

|

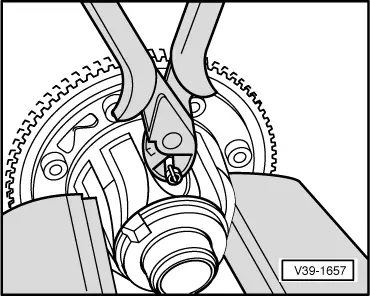

Warning!

Do not remove circlip until after pulling off drive flange as compression spring is pre-tensioned. |

|

|

|

|

|

|

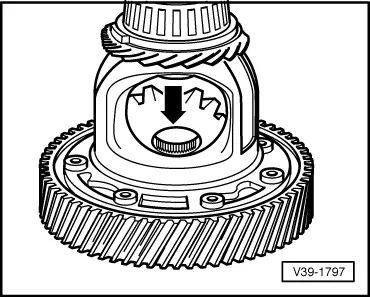

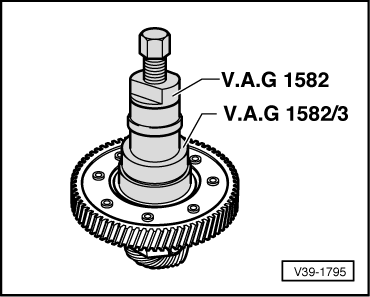

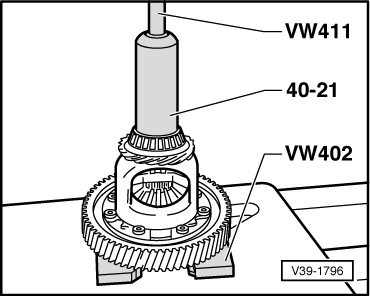

→ Fig.1 Pulling off taper roller bearing inner race

|

|

|

|

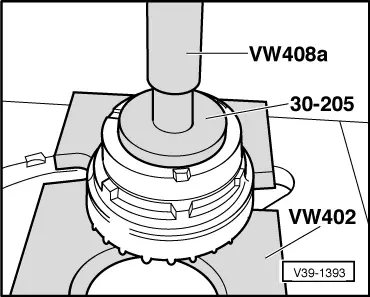

→ Fig.2 Pressing on taper roller bearing inner race |

|

|

|

→ Fig.4 Pressing in taper roller bearing outer race

|