Golf Mk3

|

Repair work on the refrigerant circuit which can only be carried out by properly trained mechanics (Specialist workshops for air conditioning systems)

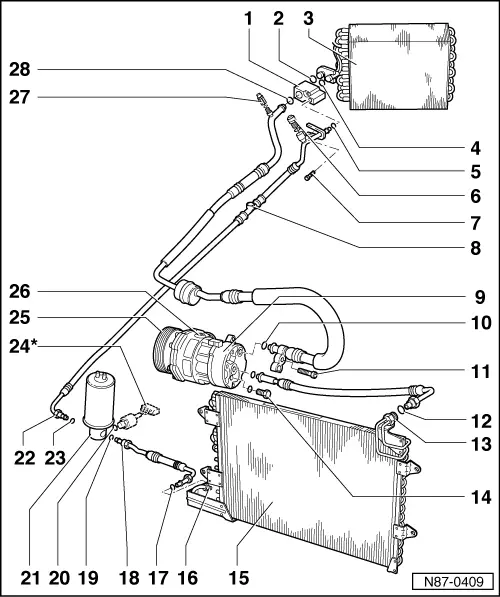

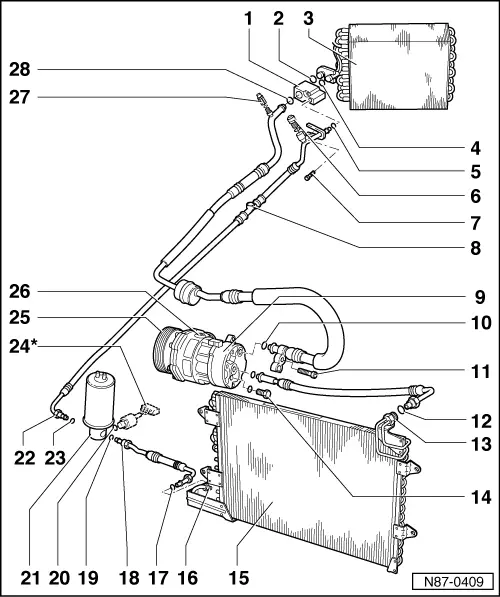

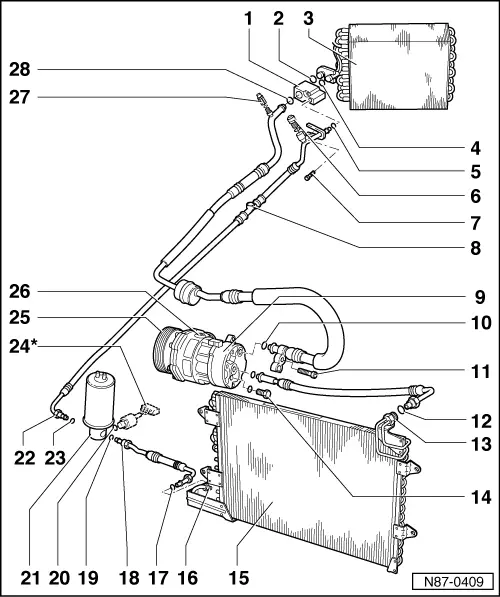

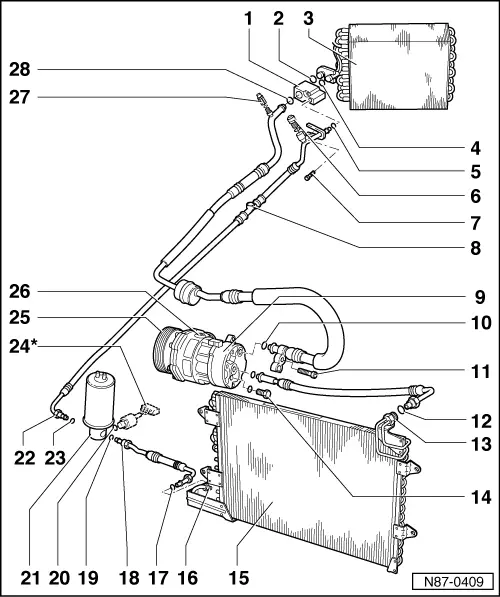

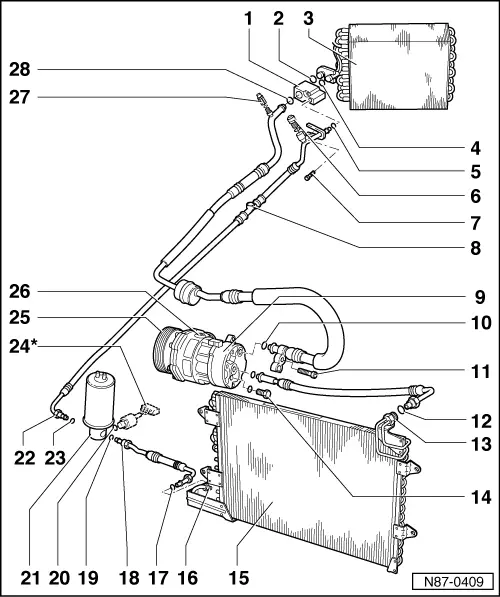

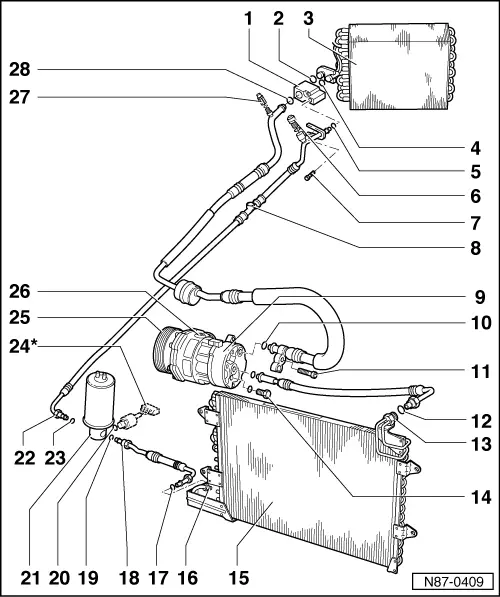

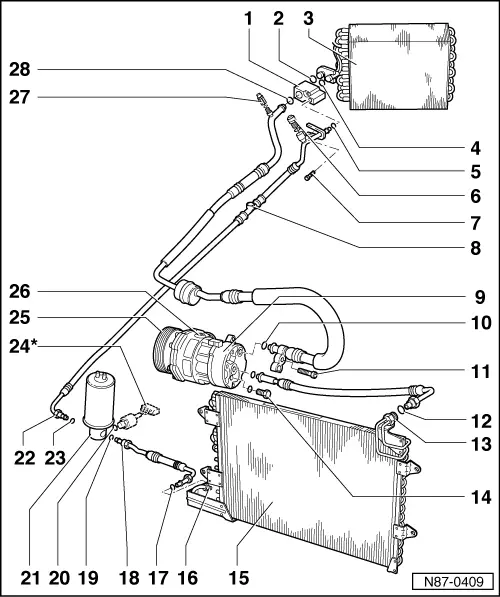

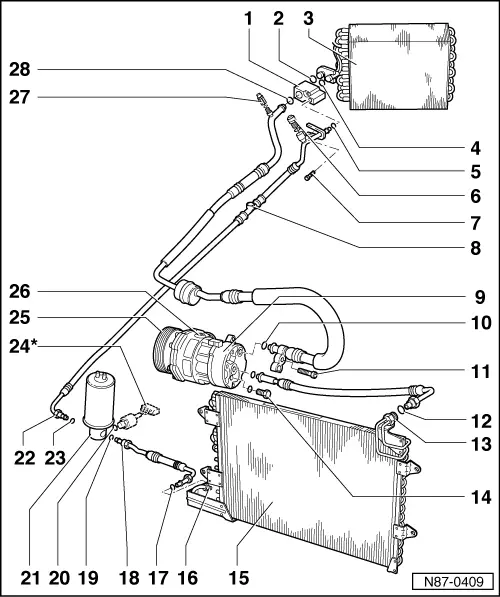

Servicing components in the refrigerant circuit

|

|

|

|

Notes:

|

|

|

Function

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

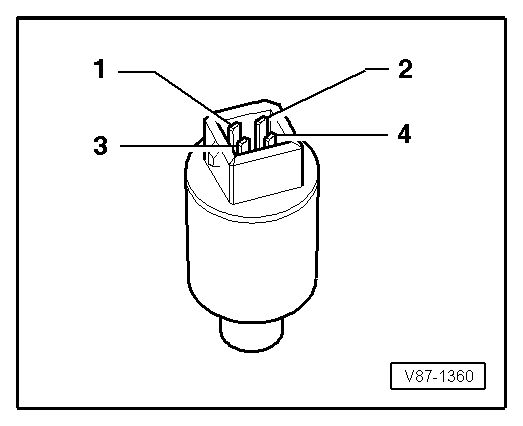

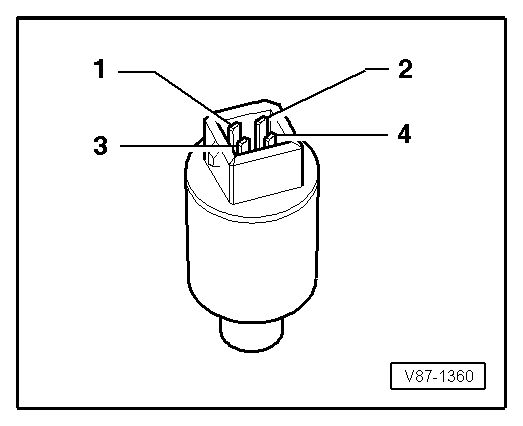

→ Checking switch part:

Switch part between chamber 3 and chamber 4 of connector housing switches radiator fan -V7- via radiator fan control unit -J293- to 2nd speed when refrigerant pressure rises.

Evaluating the checks on the pressure switch for the air conditioner -F129-

|

|

|

|

→ To assess the air conditioning system output perform and evaluate the following checks:

|