Golf Mk3

|

Repair work on the refrigerant circuit which can only be carried out by properly trained mechanics (Specialist workshops for air conditioning systems)

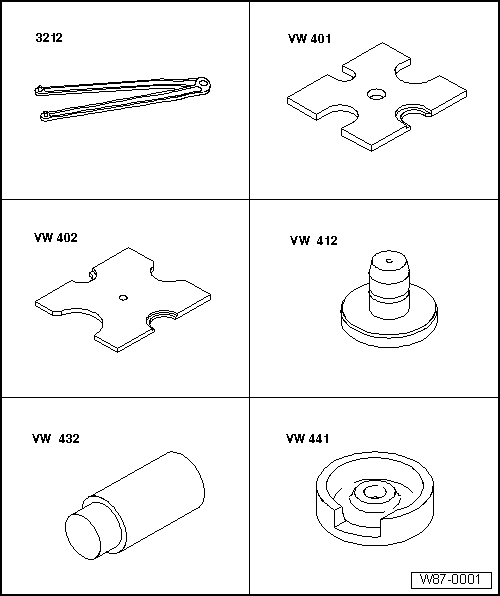

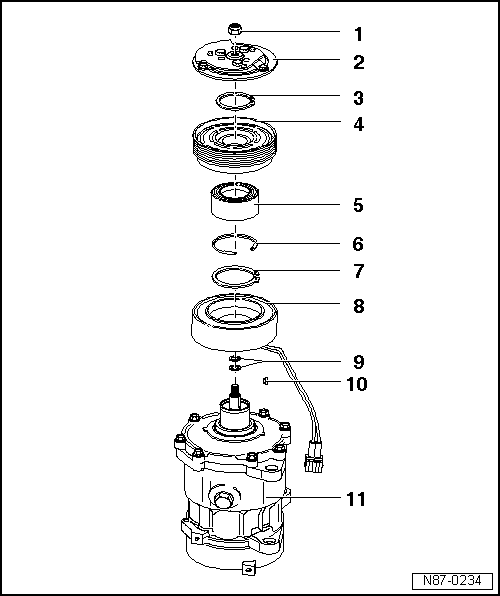

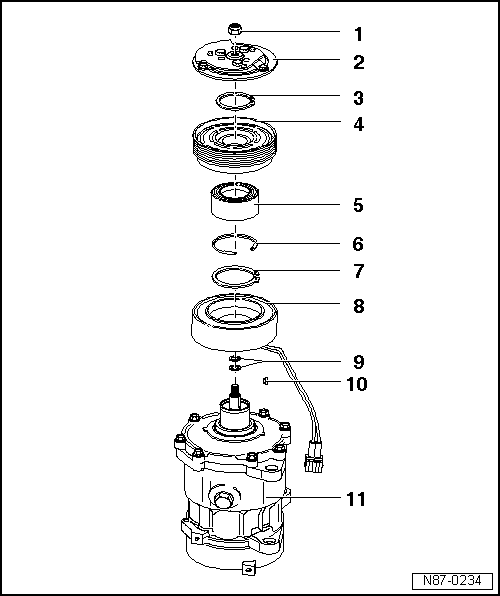

Servicing magnetic coupling -N25- when compressor is removed; Manufacturer Sanden

|

|

|

|

|

|

|

|

|

|

Perform following work first:

Notes: Releasing refrigerant into the environment is a punishable offence.

|

|

|

|

|

|

Notes: An overheating protection is installed in the magnet windings. The overheating protection interrupts the magnet windings as soon as the magnetic coupling overheats (for example a binding compressor).

|

|

|

Removing magnetic coupling from compressor and reinstalling |

|

|

|

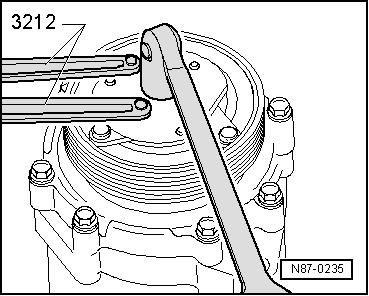

→ Fig.1 Undoing hexagon nut

|

|

|

|

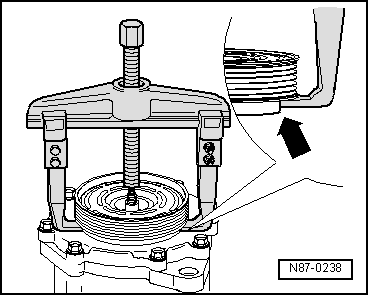

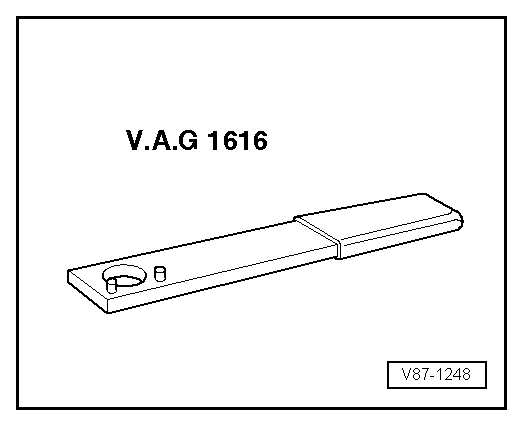

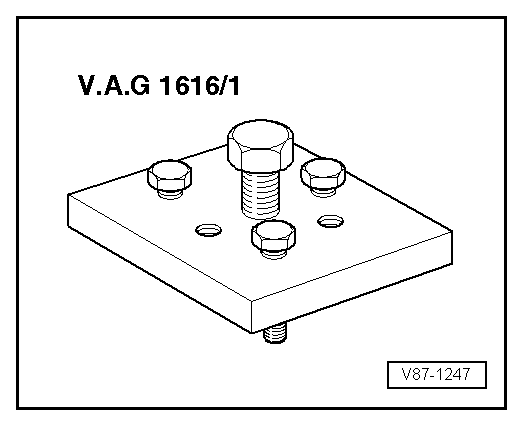

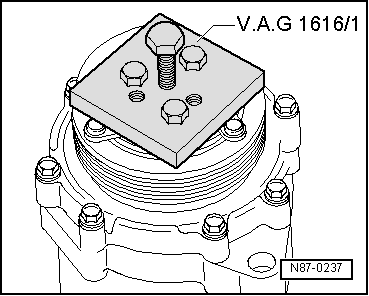

→ Fig.2 Pulling off coupling plate Note: The three hexagon bolts of the V.A.G 1616/1 have a 1/4" thread. |

|

|

|

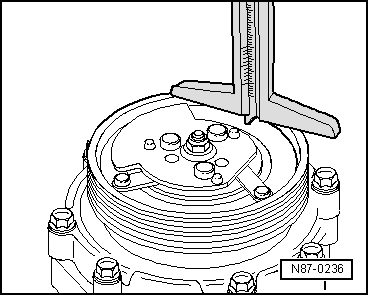

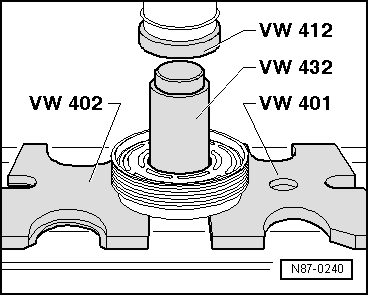

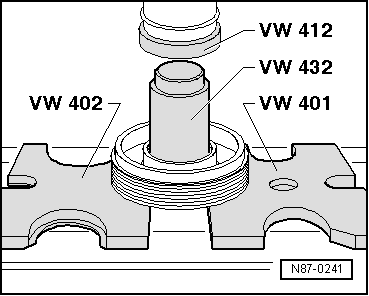

→ Fig.4 Pressing off ball bearing |

|

|

|

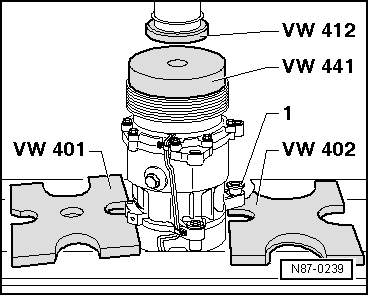

→ Fig.5 Pressing in ball bearing |

|

|

|

→ Fig.6 Pressing on magnetic coupling belt pulley Note: Place compressor down flat, otherwise there is a danger that the belt pulley will be deformed when pressing on.

|