Golf Mk3

|

Servicing clutch

Servicing clutch

|

|

|

|

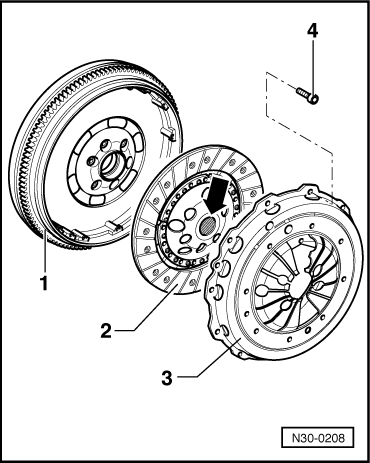

Modifications to clutch for Golf syncro saloon with 1.9 ltr. - 66 kW turbo diesel engine =>Page 30-26 (Gearbox removed) Notes:

|

|

|

=> Repair group13

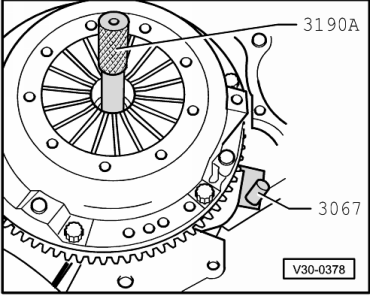

Note: Remove corrosion from input shaft splines and clutch plate hub splines, clean and apply only a very thin coating of grease Part No.: G 000 100 to the input shaft splines. The clutch plate must move to and fro freely on shaft. Excess grease must be removed. |

|

|

|

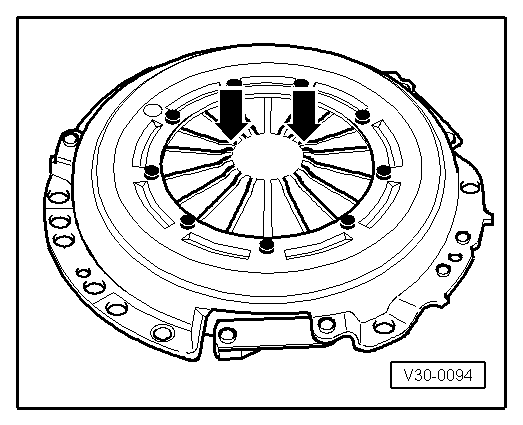

Note: Pressure plates are protected against corrosion. Only the contact surface may be cleaned.

|

|

|

|

Clutch

=> Repair group13

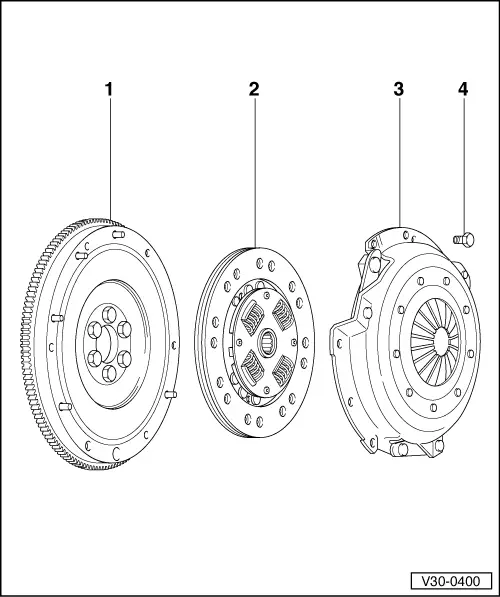

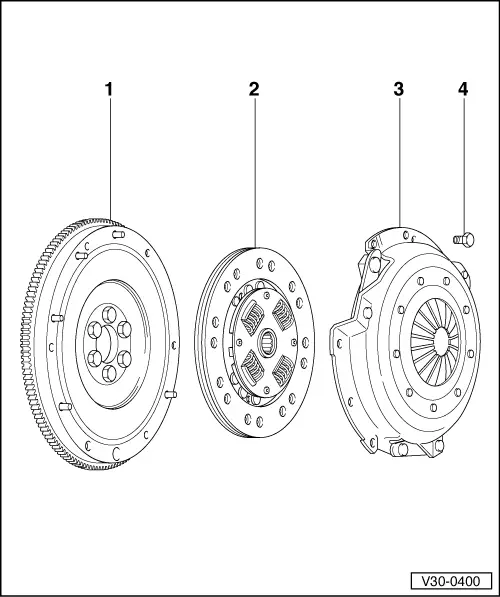

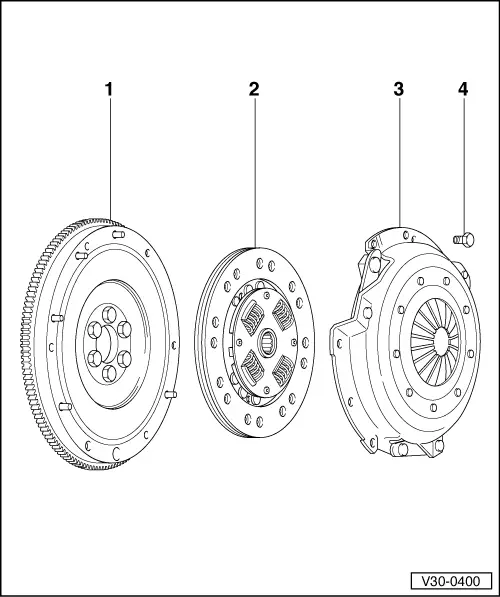

Installation position: The shorter end of the hub (arrow) faces to pressure plate -3-.

Tightening torque Pressure plate multi point socket head bolts -4- to flywheel: 13 Nm.

|