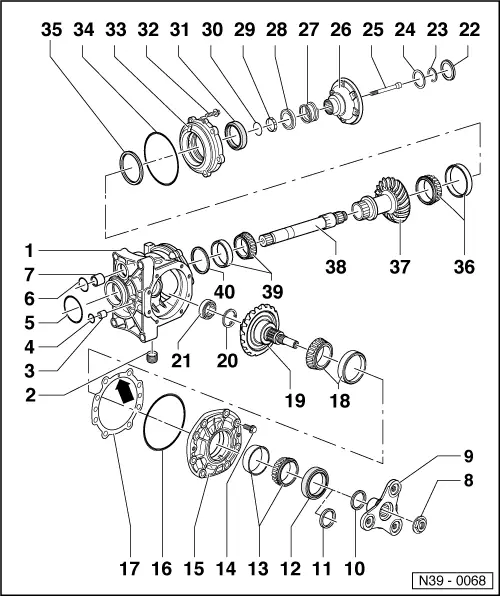

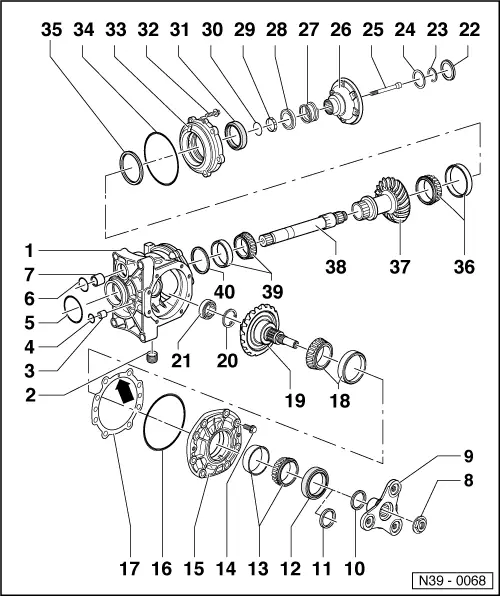

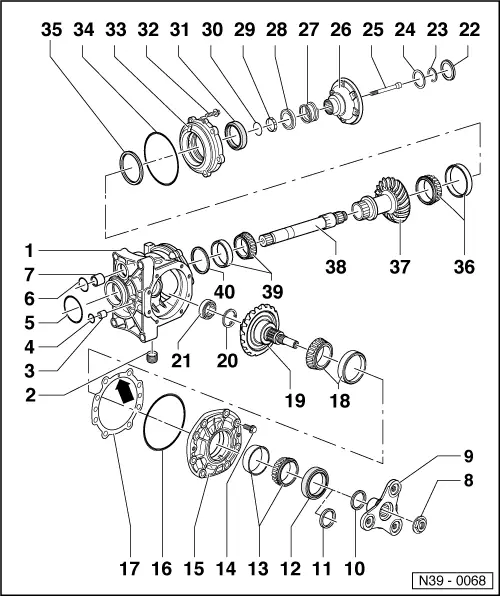

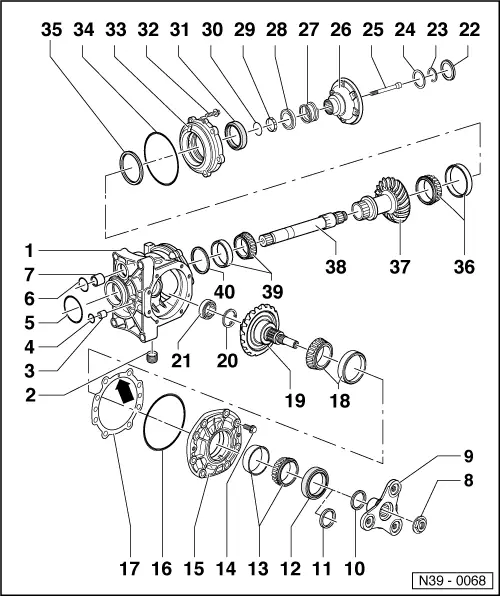

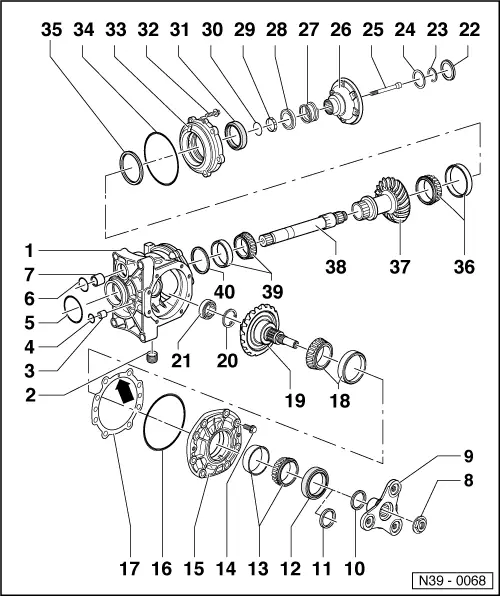

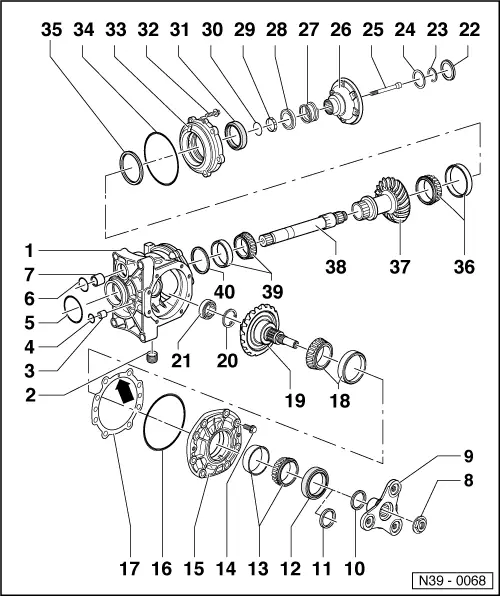

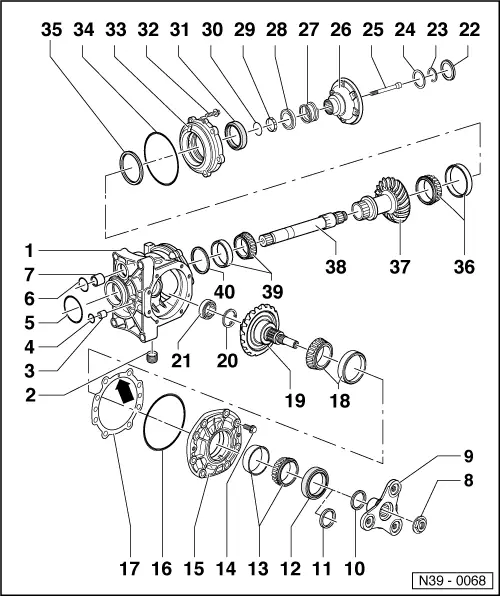

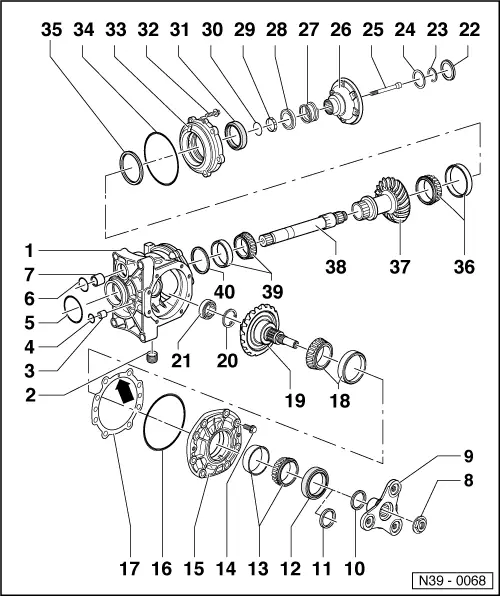

Golf Mk3

|

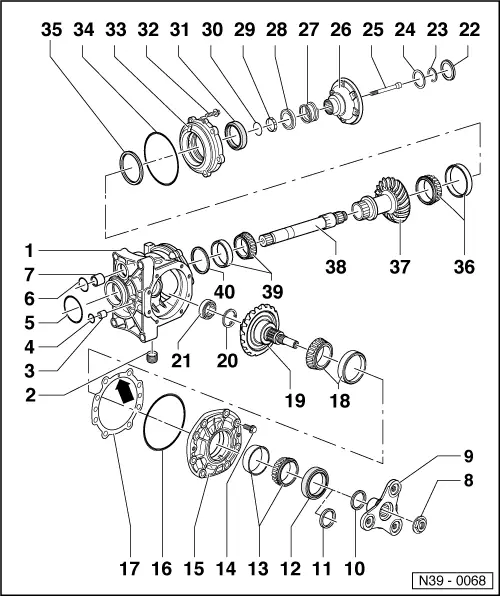

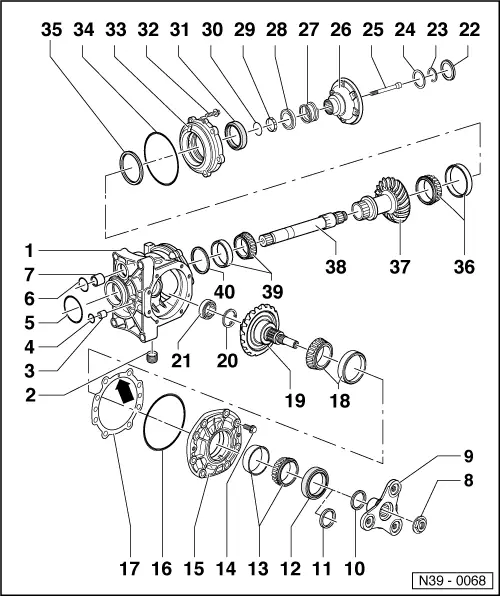

Dismantling and assembling bevel box

Assembly overview

Dismantling and assembling sequence Note: When renewing or

Note differences between gearboxes for vehicles with 4-Cyl. engine and 6-Cyl. injection engine. 1)

Adjustment work is required if these components are replaced |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|