|

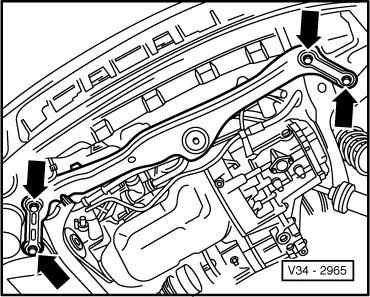

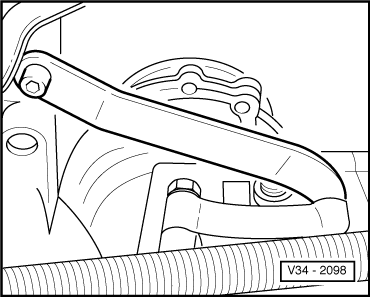

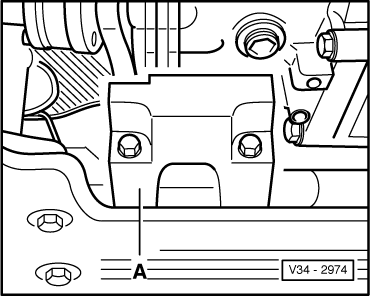

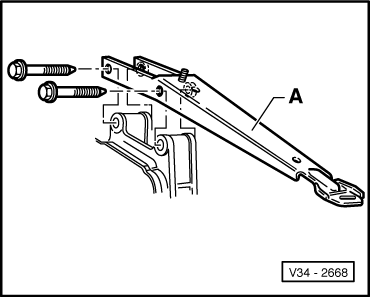

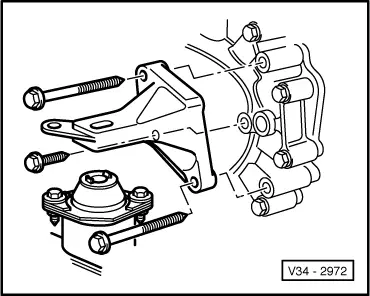

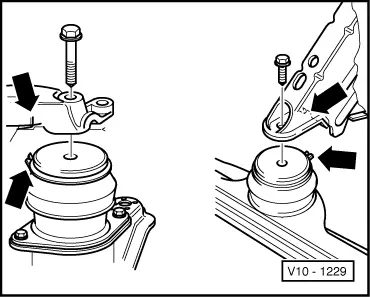

Removing and installing gearbox

Removing and installing gearbox and bevel box (Vehicles with 4 cylinder engine)

Special tools, testers and auxiliary items

-

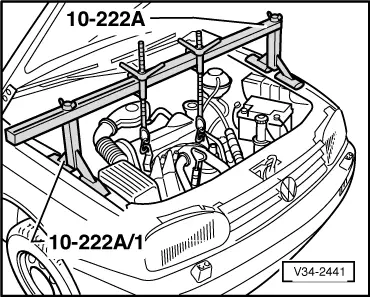

◆ Engine support bracket 10-222A with supports10-222A/1

-

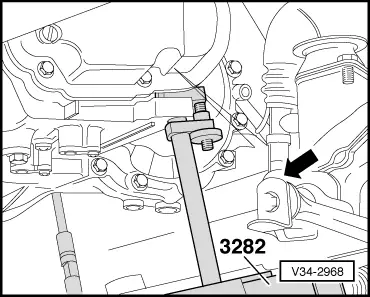

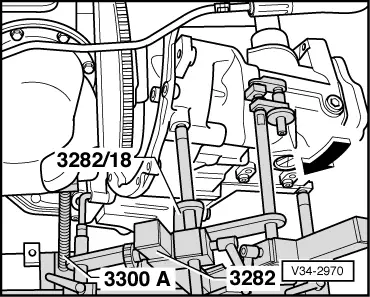

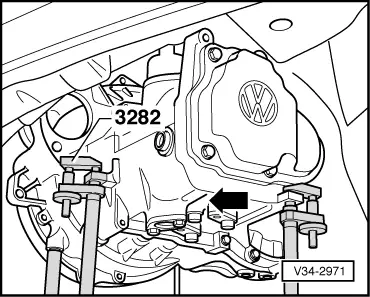

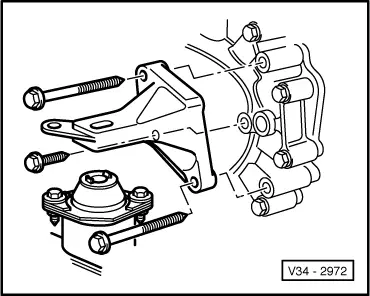

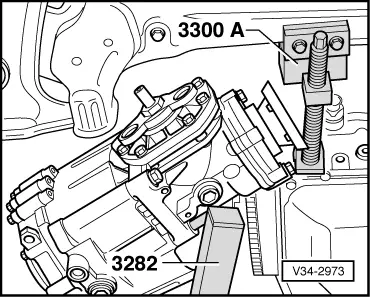

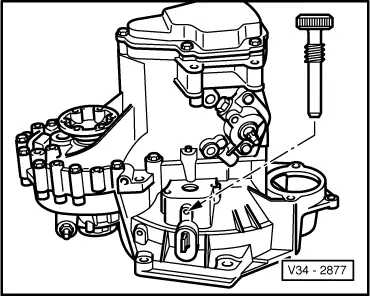

◆ Gearbox support 3282

-

◆ Alignment plate 3282/18

-

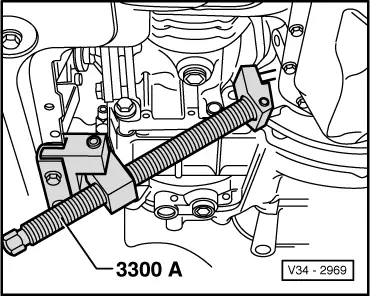

◆ Engine press tool 3300 A

-

◆ Engine/gearbox jack V.A.G 1383 A

-

◆ Torque wrench V.A.G 1332

Removing

-

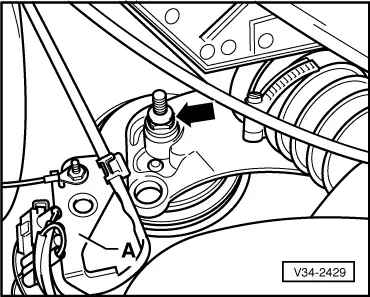

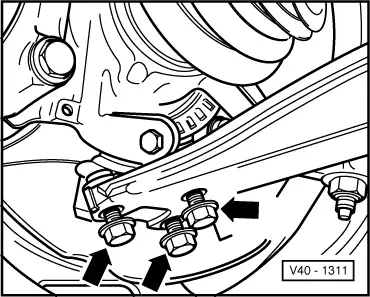

‒ Loosen hexagon nut on left drive shaft.

Note:

Only loosen and tighten drive shaft hexagon nuts with vehicle standing on its wheels. (Danger of accident).

-

‒ For vehicles with coded radio obtain radio code.

|