Golf Mk3

|

Dismantling and assembling gearbox

Adjusting 2nd and 4th gear brake -B2-

|

|

|

|

Special tools, testers and auxiliary items

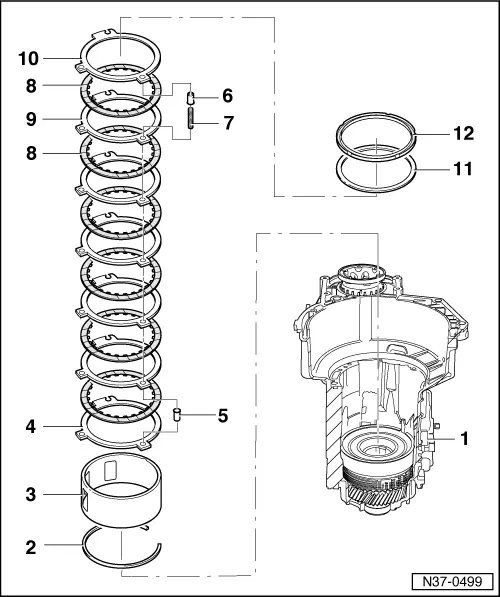

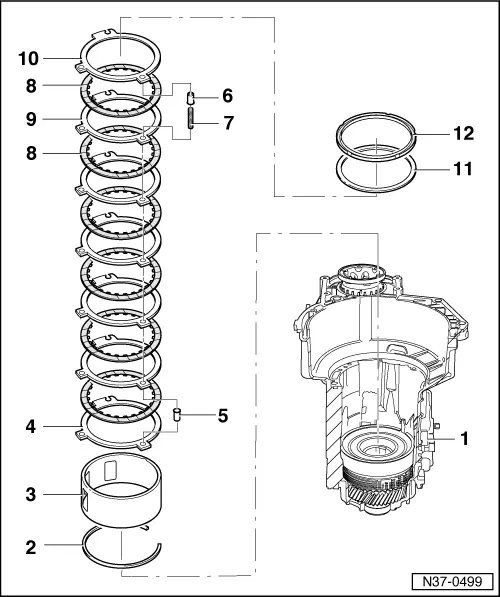

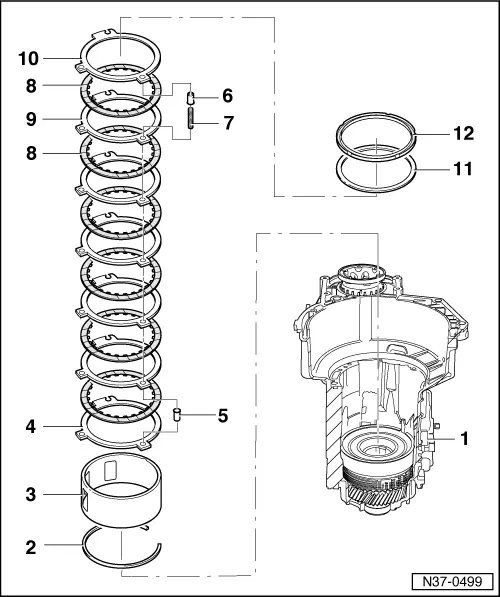

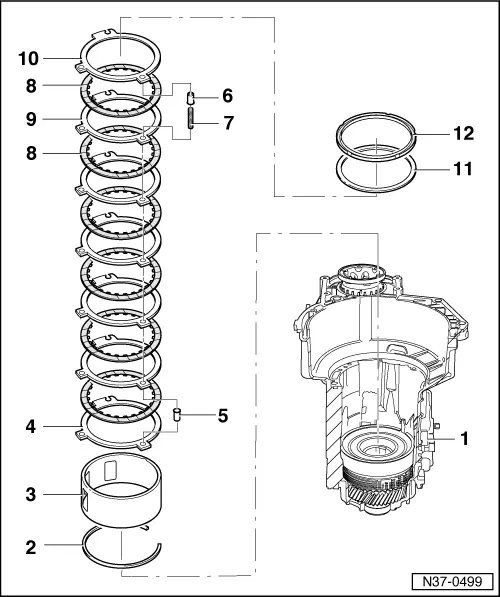

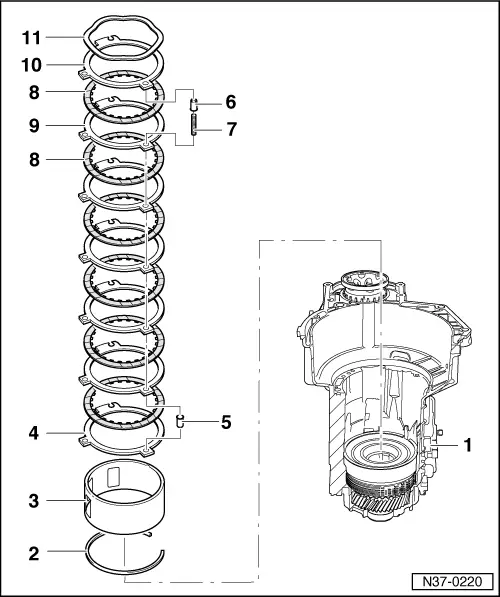

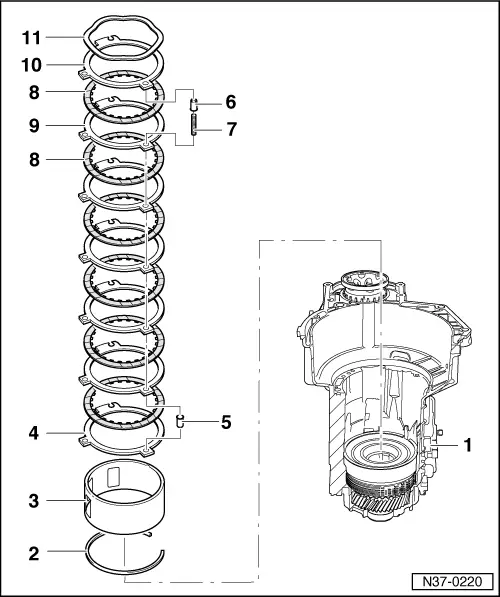

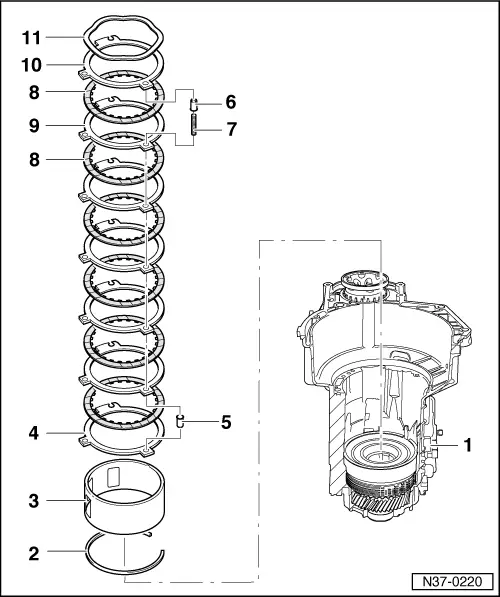

These adjustment procedures are only valid for gearboxes with a shim and retaining ring installed in brake -B2- (=> Items 11 and 12 ). With these gearboxes the brake -B2- play is determined by the thickness of the shim. On some gearboxes a corrugated spring washer is installed on the last outer plate instead of the shim and retaining ring. The brake -B2- play is then determined by the thickness of the last outer plate. Adjustment procedure for these gearboxes . |

|

|

|

|

|

|

|

|

Determining shim(s) The thickness of the shim(s) is determined by gap x. For this the formula |

|

|

|

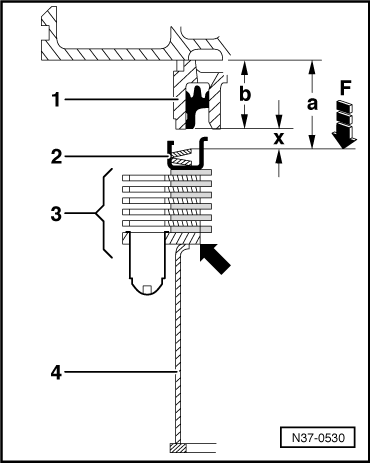

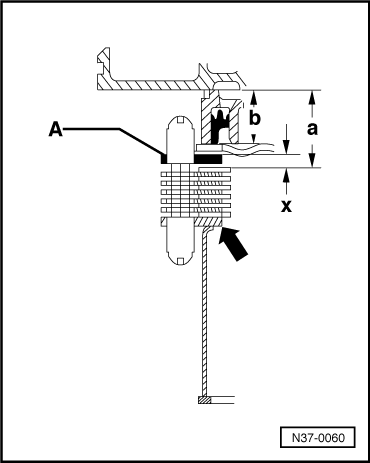

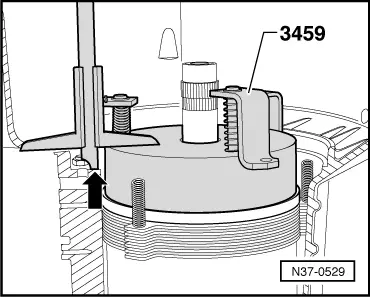

→ Gap x = a - b - 2.65 mm must be used. The measuring points are shown in the illustration to help understanding the formula. Special tool 3459, which exerts a force -F- onto the plate packet via the retaining ring, is not illustrated. Determining dimension a => Page 37-133 . Determining dimension b => Page 37-135 . 2.65 mm - The amount for settling is taken into account by force F. 1 - ATF pump 2 - Retaining ring 3 - Plates for -B2- without last outer plate 4 - Supporting tube First outer plate -arrow- and last outer plate (do not install to measure!) are always 3 mm thick. |

|

|

|

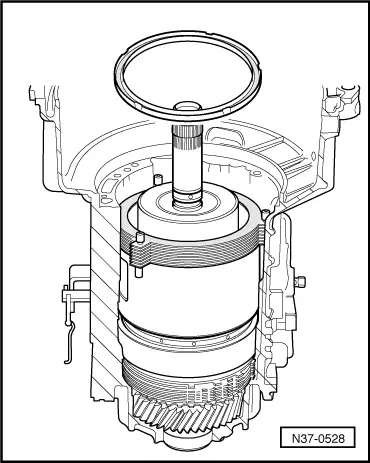

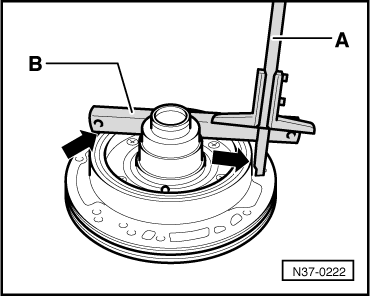

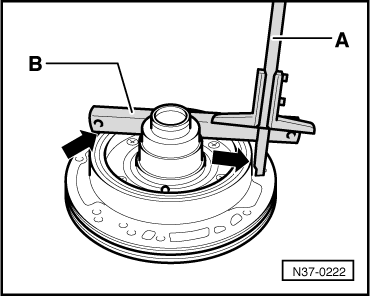

Calculating dimension "a": Assemble planetary gearbox up to the last -B2- inner plate, => Page 37-91 . The last outer plate and shim are not installed.

The plate packet for -B2- is now pressed together for the measurements. |

|

||||||||||||||||||||

Example:

Gap x = a - b - 2.65 mm Gap x = 27.3 - 20.3 - 2.65 mm = 4.35 mm

Table of "Shims":

|

|

|

|

|

|

|

Adjusting 2nd and 4th gear brake -B2- Special tools, testers and auxiliary items

This adjustment instruction is only valid for gearboxes where a corrugated spring washer in brake -B2- on the last outer plate is installed (=> Items 10 and 11 ). These gearboxes have the code letters: CLB, DLL, CLK, DKS, CKX, DKR, CKZ, DAB, CKY, CLA With these gearboxes the brake -B2- play is determined by the thickness of the last outer plate(s).

|

|

|

|

|

|

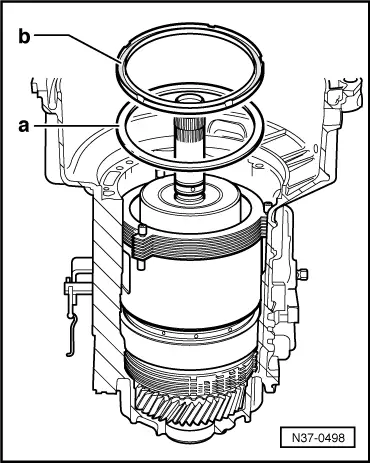

Calculating thickness of last outer plate -A- The thickness of the last outer plate(s) is determined by gap "x". For this the formula |

|

|

|

→ Gap x = a - b - 3.6 mm must be used. The illustration shows the assembled brake -B2- in the gearbox. Special tool 3459, which exerts a force on the pack of plates, is not illustrated. Determining dimension b => Page 37-143 . 3.6 mm - This amount allows for the settling caused by the force exerted by special tool 3459. First outer plate -arrow- is always 3 mm thick. Calculating "a": Assemble planetary gearbox up to the last inner plate of -B2-, Page 37-91 . The last outer plate, the last 3 spring caps and the corrugated spring washer are not installed.

The plate packet for -B2- is now pressed together for the measurements. |

|

|||||||||

Dimension a = Height of 3459 in mm - measured value Example:

Calculating dimension"b": |

|

||||||||||||||||||||

Example:

Gap x = a - b - 3.6 mm Gap x = 30.2 - 20.6 - 3.6 mm = 6.0 mm

Table of "plates":

|