Golf Mk3

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

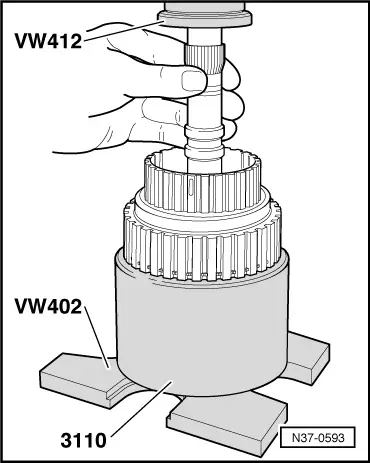

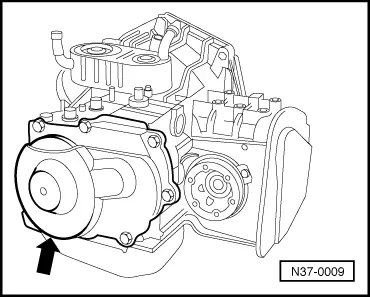

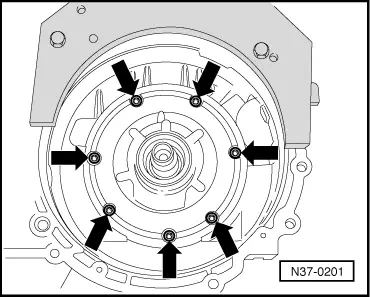

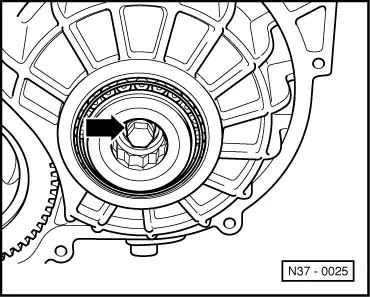

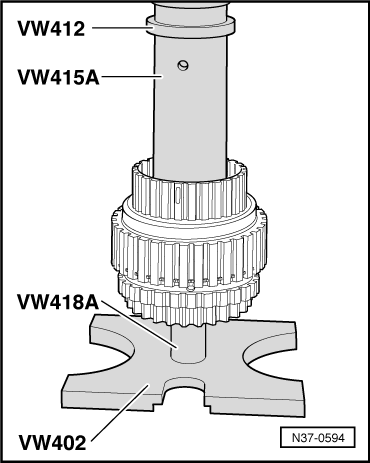

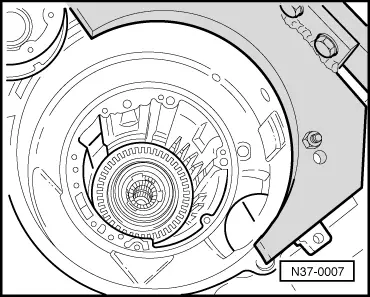

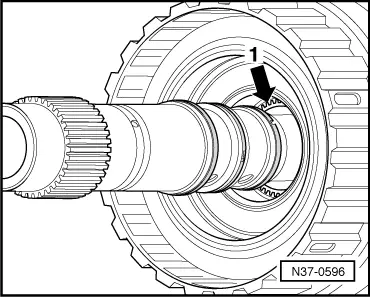

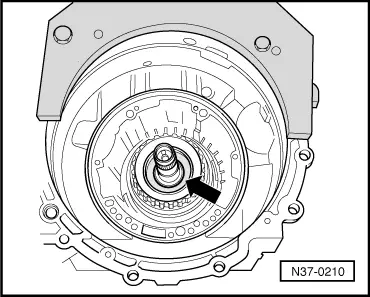

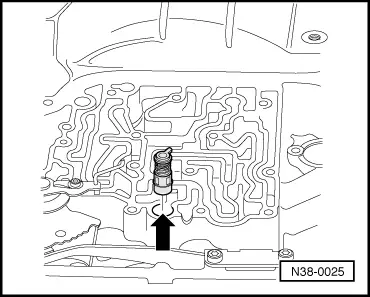

On gearboxes from gearbox build date 14 04 7 the clutches -K1- and -K3- are pressed together. Clutch -K1- must only be pressed off -K3- if one of the clutches is to be dismantled or renewed. Pressing -K1- off -K3- . |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

=> Repair group 01; Electrical/electronic components and fitting locations

|

|

|

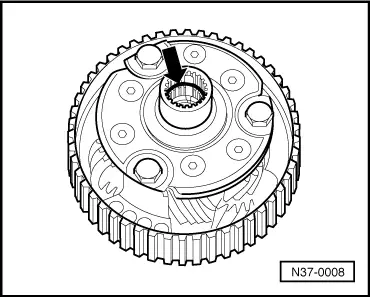

Pressing clutch -K1- off -K3- On gearboxes from gearbox build date 14 04 7 the clutches -K1- and -K3- are pressed together. |

|

|

|

|

|

|

|

|

|

|

|

|

Special tools, testers and auxiliary items

|

|

|

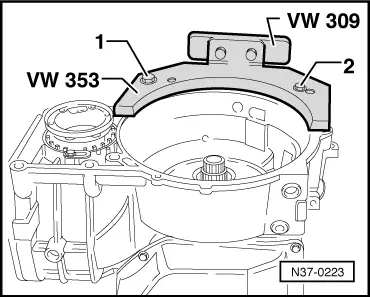

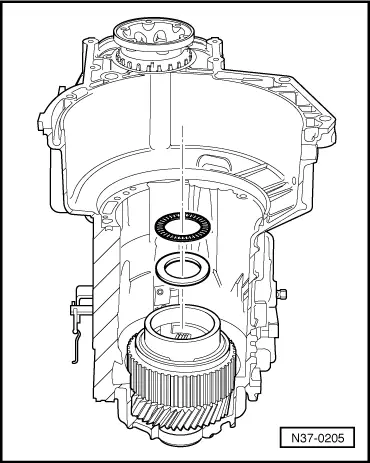

After replacing planet carrier, adjust => Page 37-106 . |

|

|

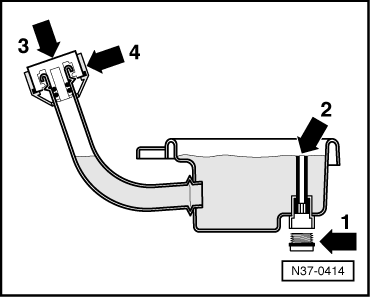

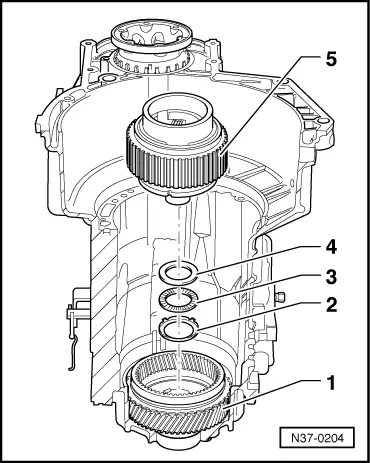

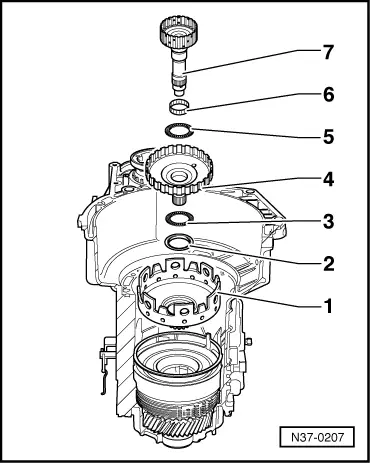

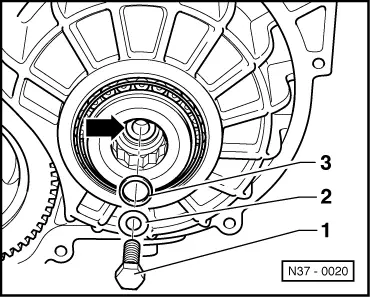

1 - Input gear is installed in gearbox housing => Page 37-68 . 2 - Axial needle bearing washer, insert smooth side into input gear. 3 - Axial needle bearing 4 - Axial needle bearing washer 5 - Install planet carrier with seal fitted |

|

|

|

|

|

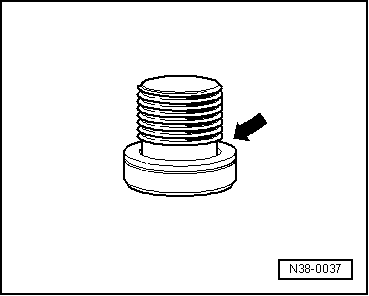

Thickness of pressure plate varies according to number of plates, replacement parts are allocated according to gearbox code letters.

|

|

|

|

When replacing

then adjust -B1-, => Page 37-114 .

|

|

|

=> Repair group 01; Electrical/electronic components and fitting locations

|

|

|

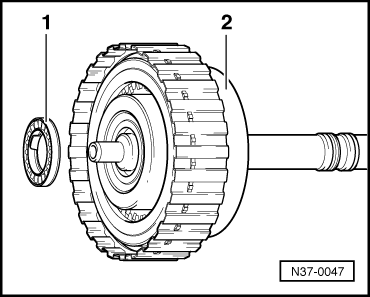

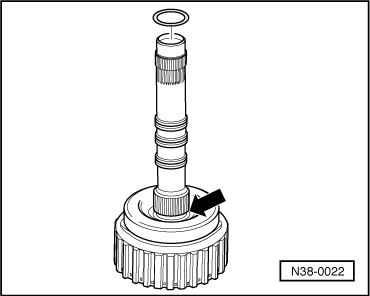

1 - Large sun wheel 2 - Needle bearing washer

3 - Axial needle bearing 4 - Large input shaft 5 - Axial needle bearing 6 - Needle bearing 7 - Small input shaft |

|

|

|

|

|

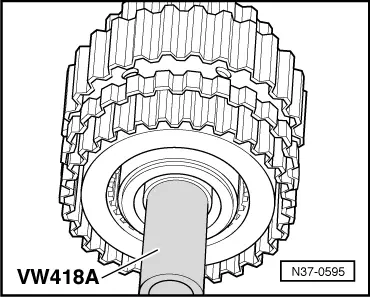

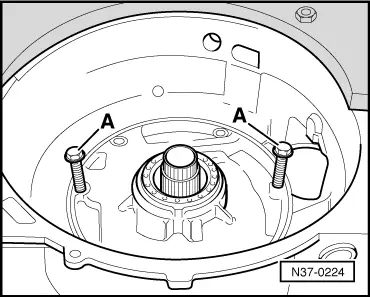

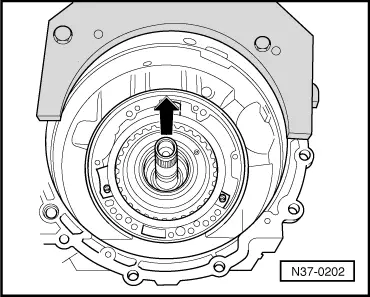

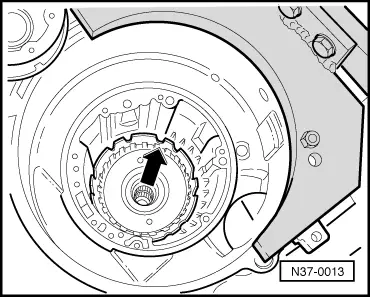

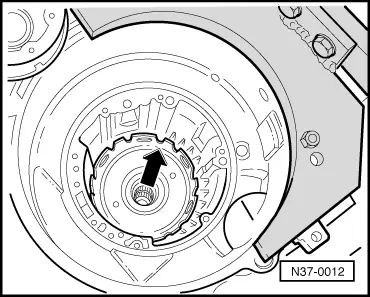

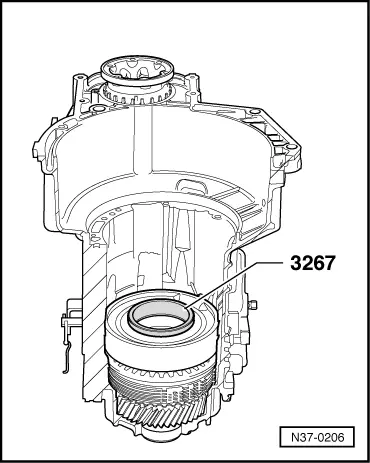

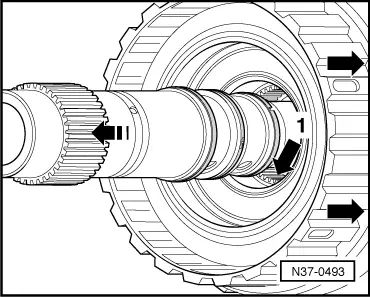

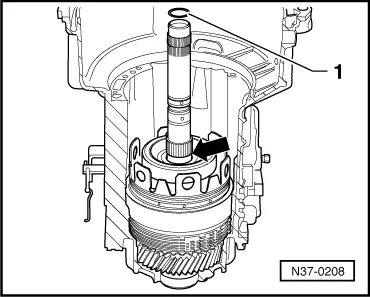

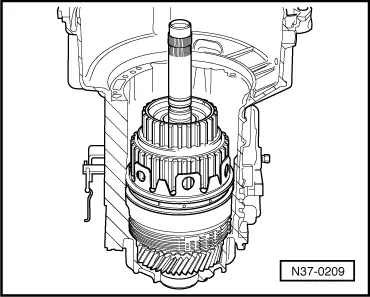

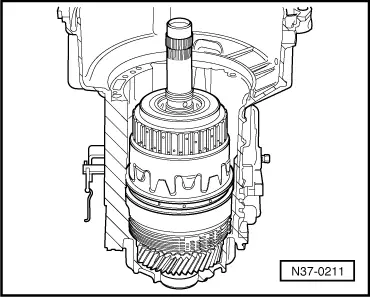

On gearboxes from gearbox build date 14 04 7 the clutches -K1- and -K3- must be pressed together before installing.

|

|

|

After pressing clutches together they can only be inserted into the gearbox together. |

|

|

|

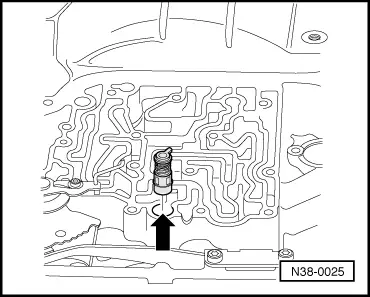

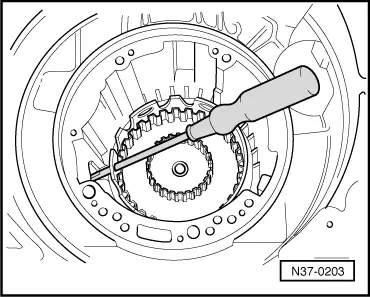

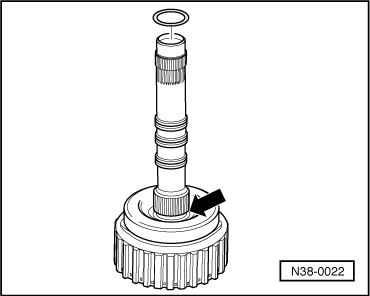

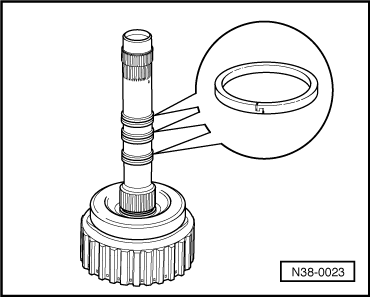

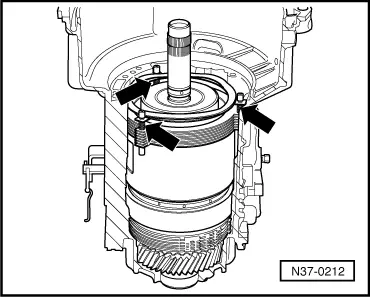

Resistance of O-ring is overcome when connecting together (by hand!) → If -K1- splines -arrow 1- are not visible.

|

|

|

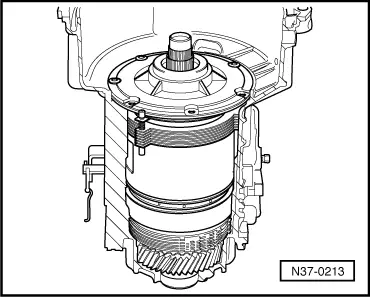

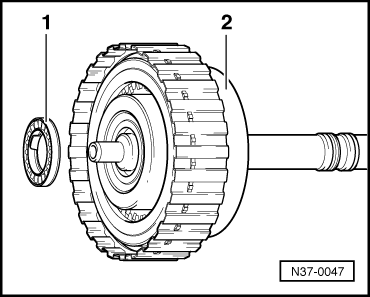

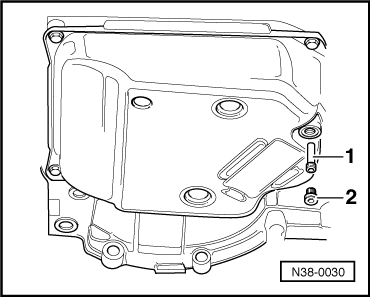

1 - Axial needle bearing with thrust washer

2 - 3rd and 4th gear clutch -K3- |

|

|

|

|

|

|

|

|

If -K1- and -K3- are pressed together, both clutches can only be inserted together. |

|

|

|

|

|

|

|

|

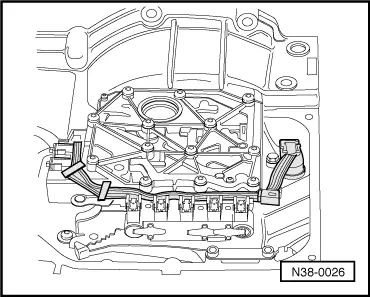

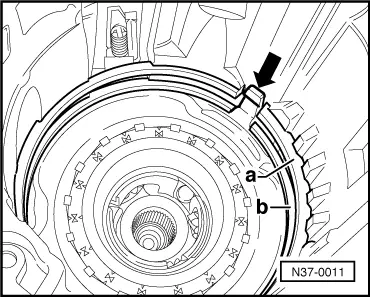

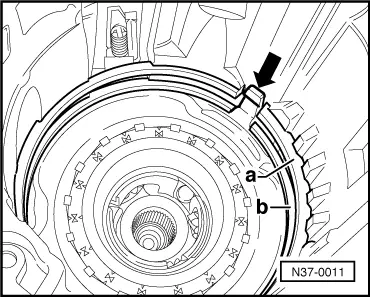

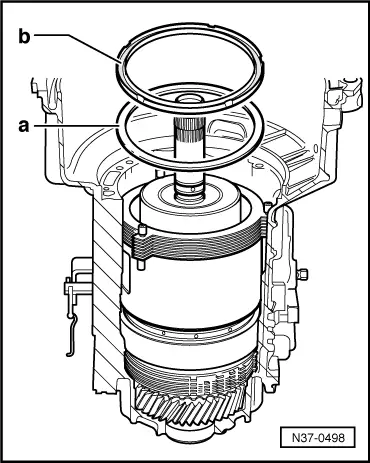

Only on gearboxes with installed corrugated spring washer is the brake clearance -B2- determined by the last outer plate thickness. Determining thickness of plate is described on => Page 37-138 . |

|

|

|

→ On all other gearboxes (with retaining ring -b-) the last outer plate is always 3 mm thick. The clearance of brake -B2- is determined by a shim -a-, on which the retaining ring -b- seats. A corrugated spring washer is not present.

Determine shim => Page 37-128 . When replacing

then the 2nd and 4th gear brakes -B2- are to be adjusted => from page 37-128 . These components are allocated as replacement parts according to gearbox code letters. |

|

|

|

|

|

Tightening torque: 8 Nm. |

|

|