Golf Mk3

|

Servicing shift mechanism

Dismantling and assembling selector mechanism

|

|

|

=> Repair group 01; Performing self-diagnosis; Read measured value block |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

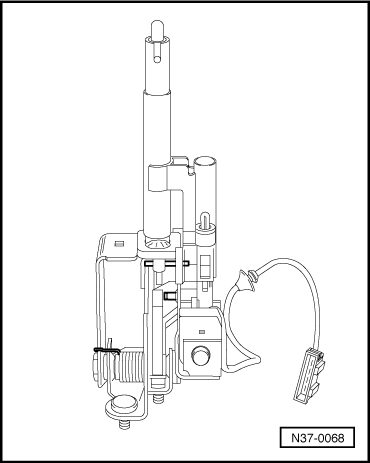

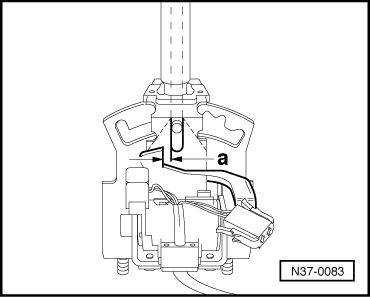

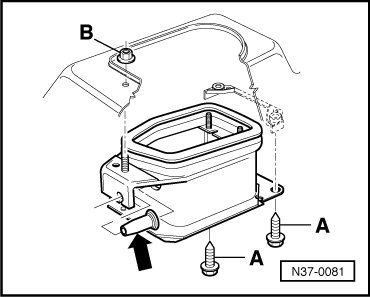

→ Fig.2 Assembling selector lever before installing Before installing selector lever in selector lever housing adjust selector lever lock solenoid -N110- => Fig. 3 and carry out functional check => Fig. 4 .

|

|

|

|

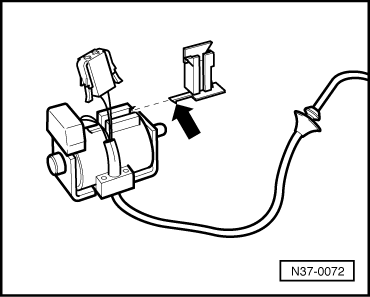

→ Fig.3 Adjusting selector lever lock solenoid -N110-

|

|

|

|

→ Fig.5 Securing selector lever cable to selector lever

|

|

|

|

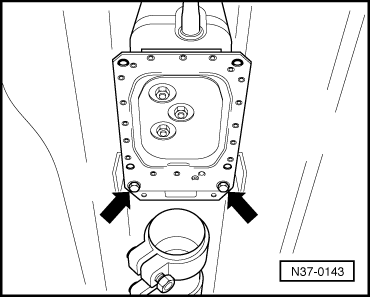

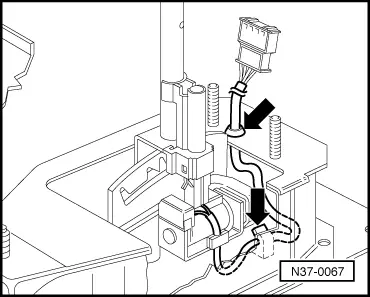

→ Fig.6 Securing wiring loom to selector lever housing

|

|

|

|

→ Fig.7 Securing indicator lighting connector

|

|

|

|

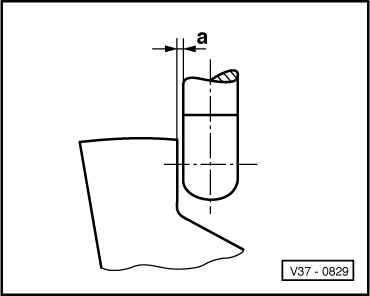

→ Fig.8 Insert boot in selector lever housing

|

|

|

|

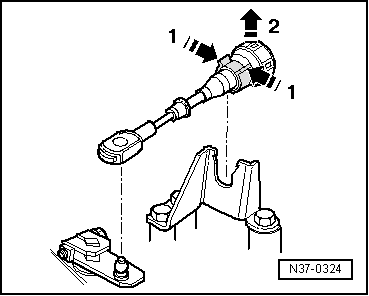

→ Fig.9 Removing clipped selector lever cable from gearbox support bracket

|