Golf Mk3

|

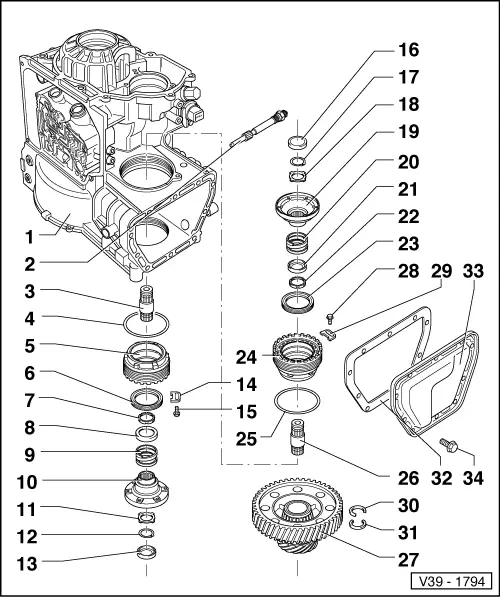

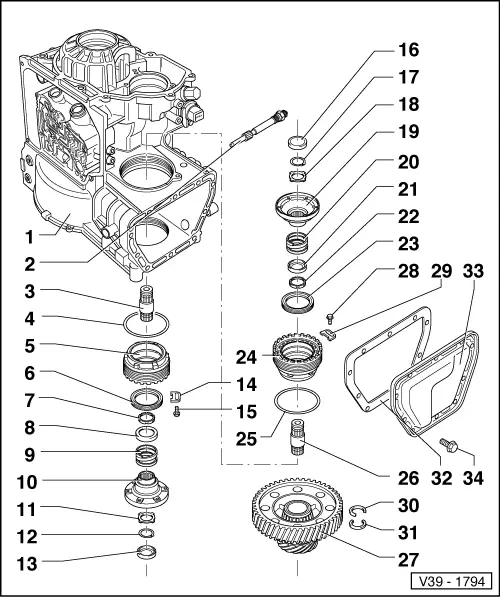

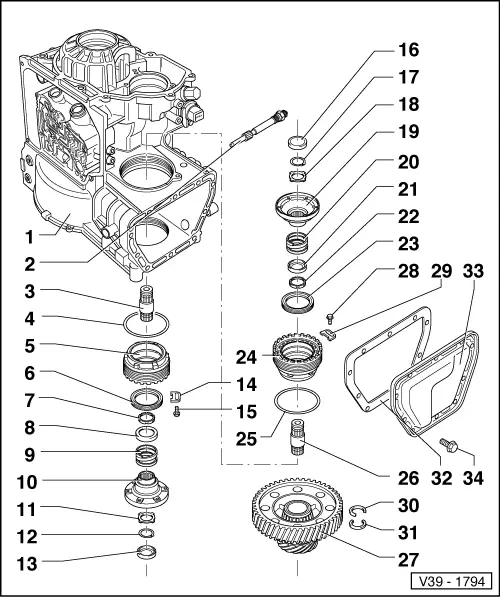

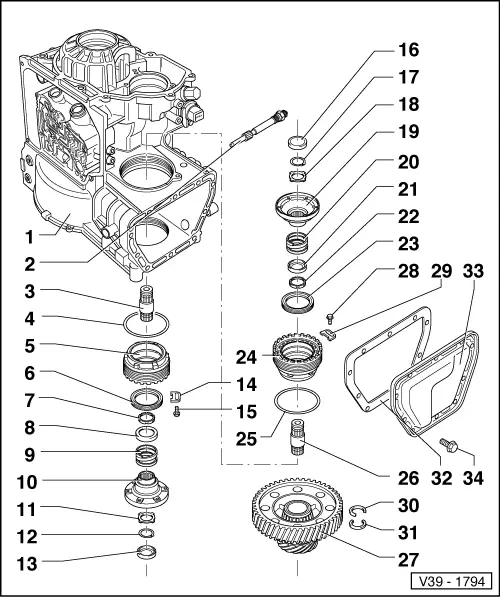

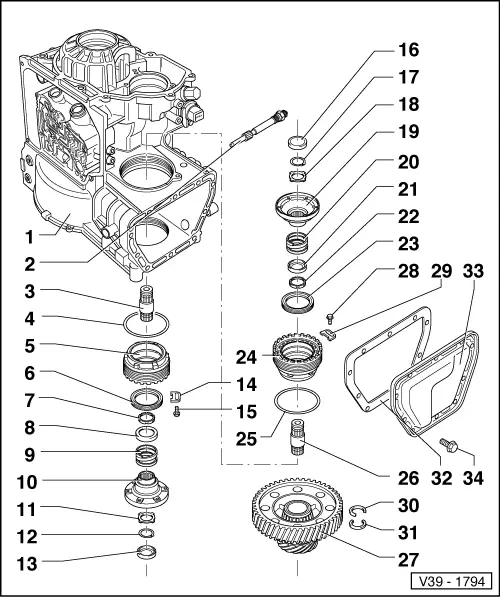

Dismantling and assembling final drive

Removing and installing differential

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

After adjusting taper roller bearings, secure bearing body and adjusting ring.

|

|

|

|

|

|

|

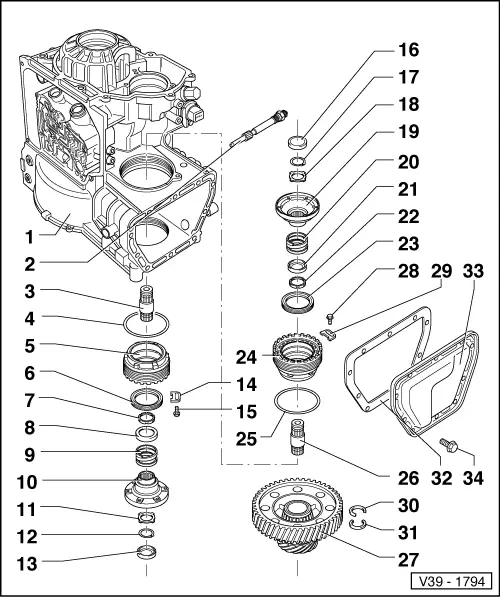

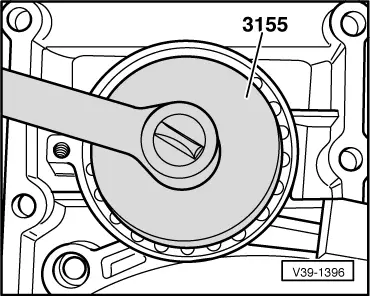

→ Fig.1 Driving in drive flange oil seal up to stop |

|

|

|

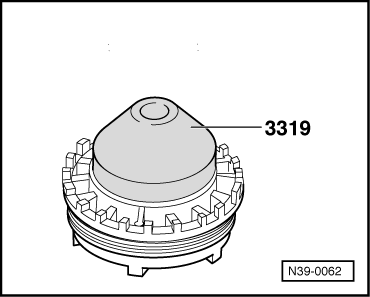

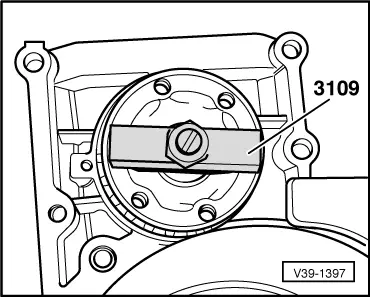

→ Fig.2 Marking adjusting ring

|

|

|

|

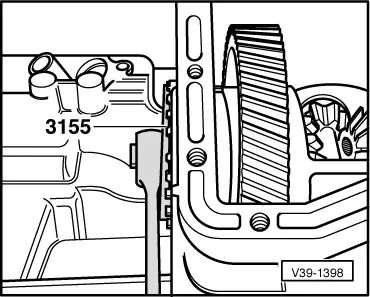

→ Fig.3 Removing adjusting ring |

|

|

|

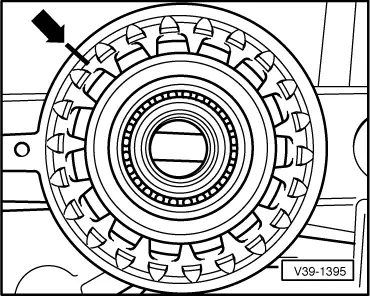

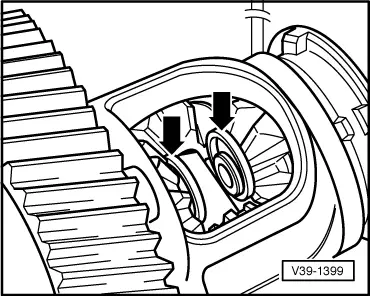

→ Fig.4 Removing and installing drive flange Drive flange can also be removed and installed with VW 391. |

|

|

|

→ Fig.5 Inserting differential and screwing in bearing body as far as stop to 150 Nm |

|

|

|

→ Fig.6 Inserting circlip (arrow)

|

|

|

|

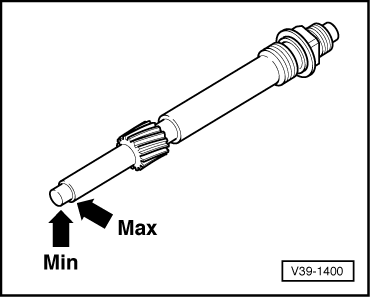

→ Fig.7 Speedometer drive

|