Golf Mk3

|

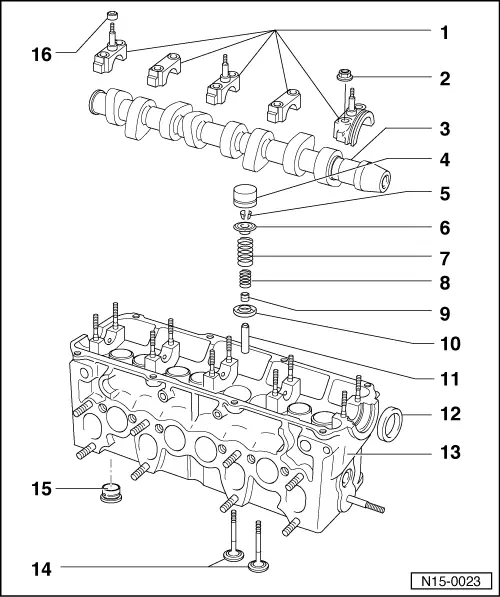

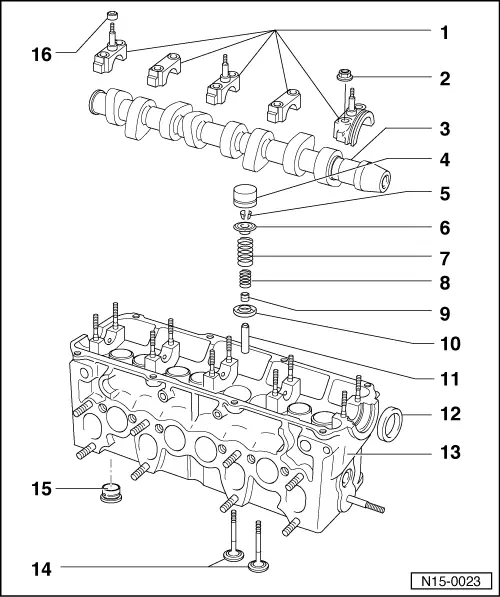

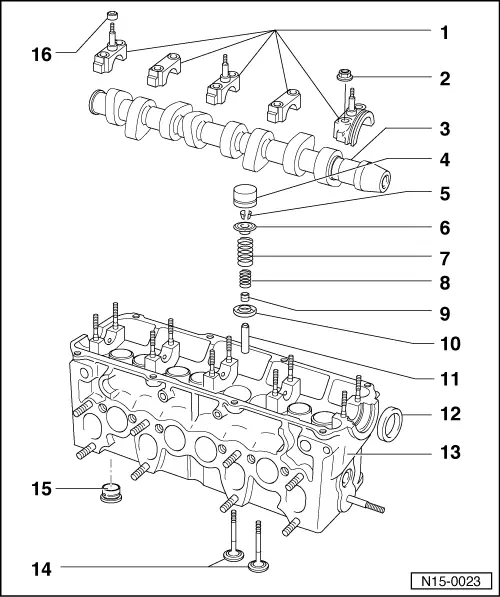

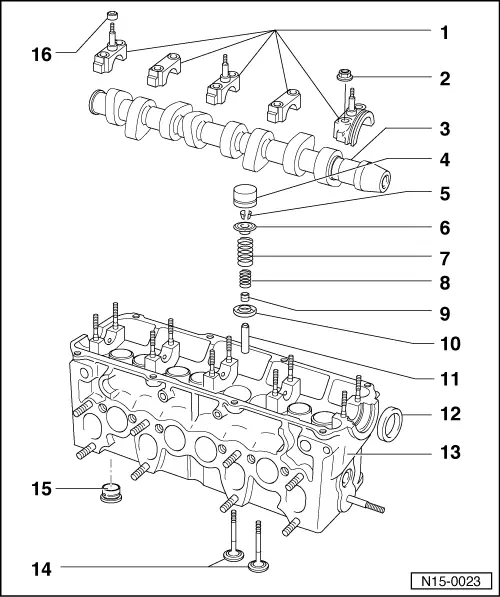

Servicing valve gear

Servicing valve gear

|

|

|

|

Note: Cylinder heads with cracks between the valve seats may be used without reducing engine life, provided the cracks are small and not more than 0.5 mm wide.

|

|

|

|

|

|

|

|

|

|

|

|

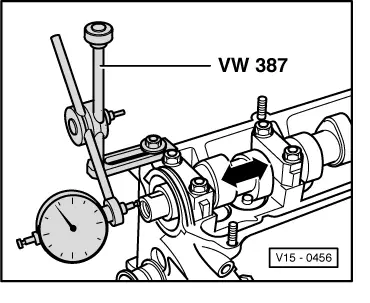

→ Fig. 1 Checking camshaft axial clearance Wear limit: max. 0.15 mm Check with bucket tappets removed and with first and last bearing caps fitted. |

|

|

|

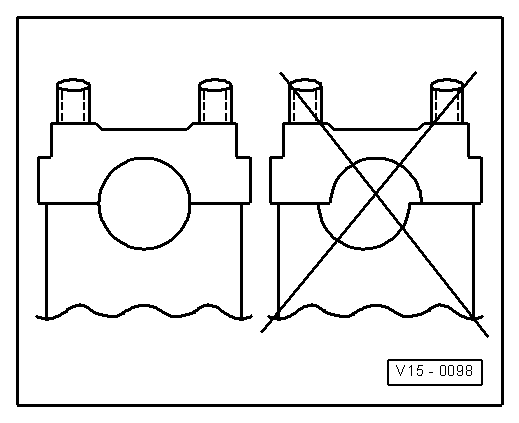

→ Fig. 2 Fitting position of camshaft bearing caps Note offset. Before installing camshaft fit bearing caps and determine fitting position. |

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

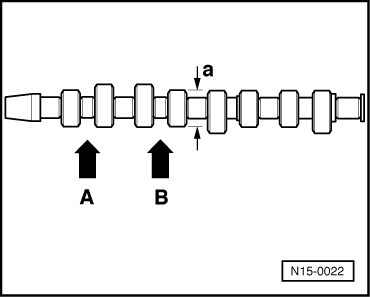

→ Fig.4 Camshaft identification, valve timing Identification

Valve timing at 1 mm valve lift

|