Golf Mk3

|

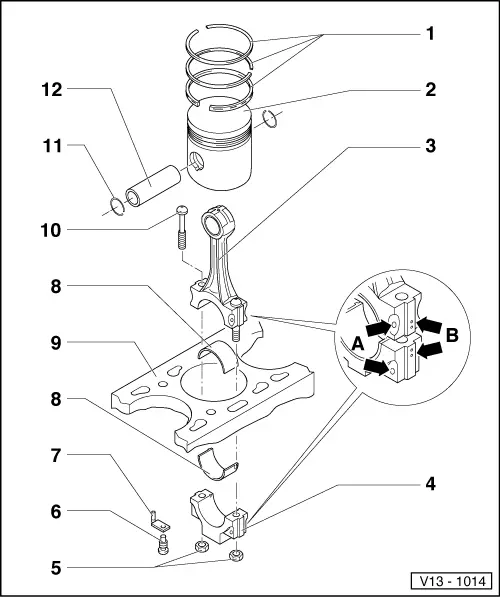

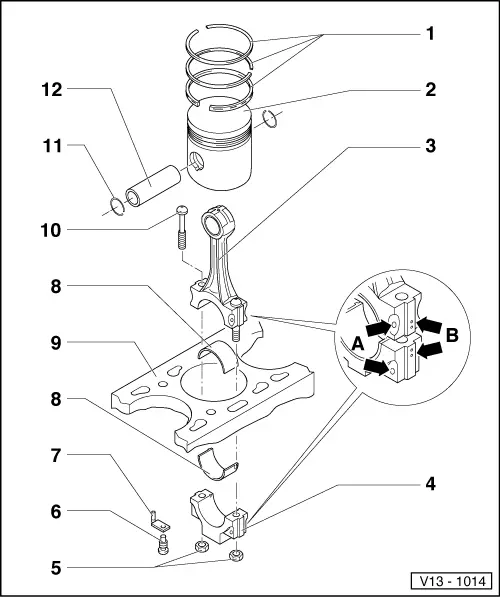

Dismantling and assembling pistons and conrods

Dismantling and assembling pistons and conrods

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||

|

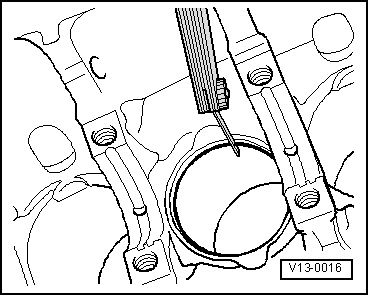

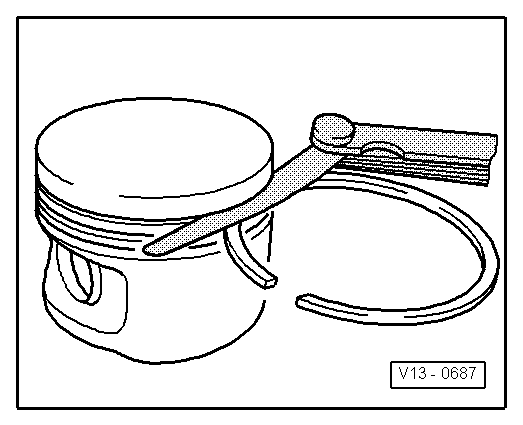

→ Fig. 2 Checking ring to groove clearance Clean groove before check.

| |||||||||||||||||

|

|

|

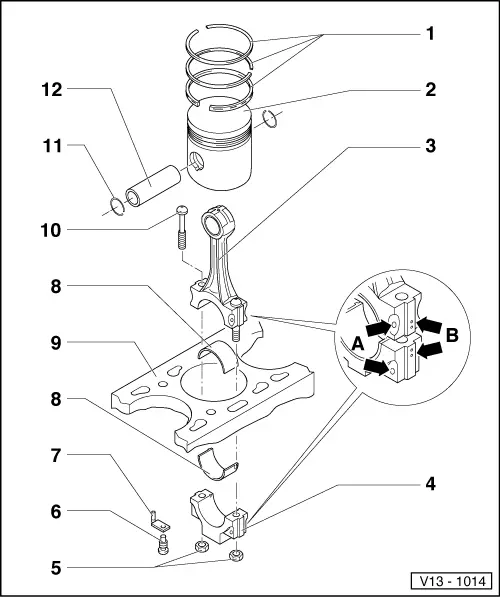

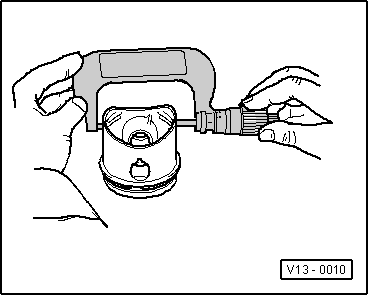

→ Fig. 3 Checking piston Special tools, testers and auxiliary items

|

|

|

|

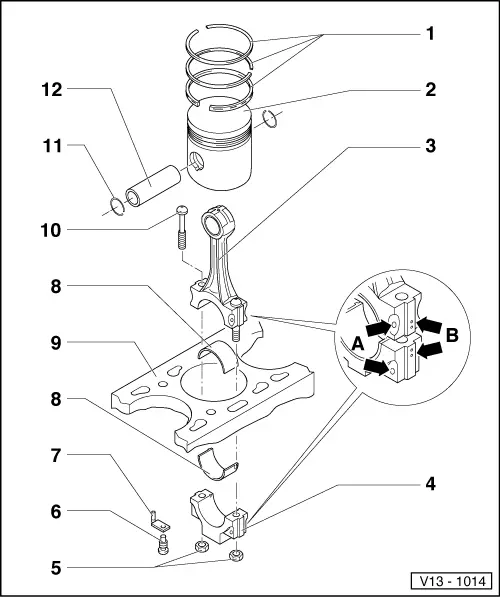

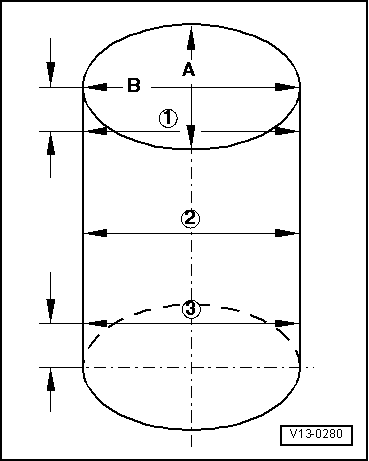

→ Fig. 4 Checking cylinder bores Special tools, testers and auxiliary items

Note: Measuring the cylinder bores must not be done when the cylinder block is mounted on a repair stand with adapter bracket VW 540, as incorrect measurements would then be possible. |