Golf Mk3

|

|

Engine code AEA, AEE, AEX, APQ

|

|

|

Installing

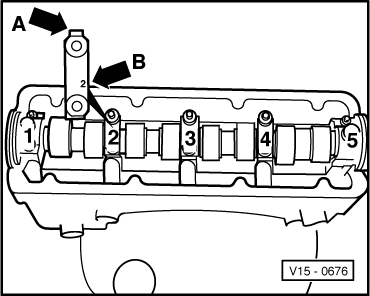

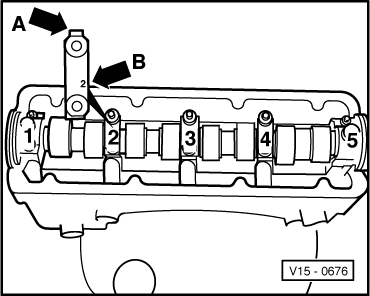

Note: Note fitting position of bearing cap: Wider cast lug -arrow A- to intake side and the bearing cap number -arrow B- readable from the exhaust side.

The rest of the assembly is basically a reverse of the dismantling sequence. Installing toothed belt and adjusting timing => Page 13-20 . Note: When new tappets have been installed the engine must not be started for about 30 minutes. Hydraulic compensation elements must settle (otherwise valves will strike pistons). |