Golf Mk3

| Dismantling and assembling pistons and conrods |

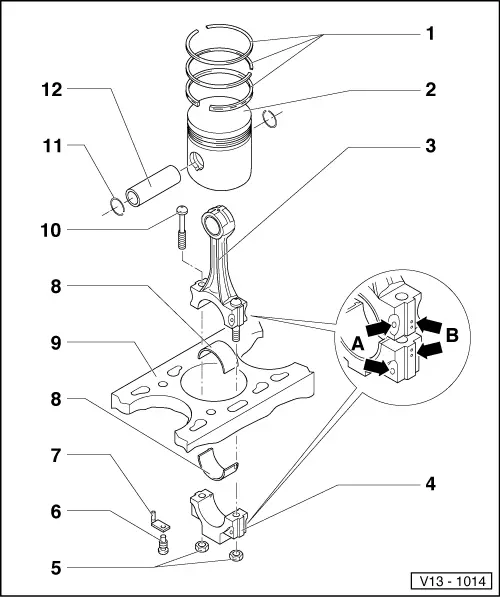

| 1 - | Piston rings |

| q | Offset gaps by 120°. |

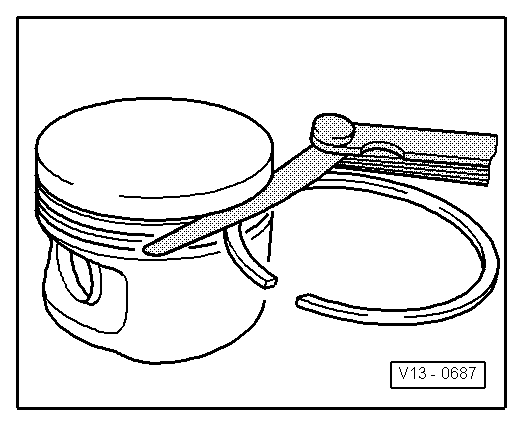

| q | Use piston ring pliers to remove and install |

| q | “TOP” faces towards piston crown. |

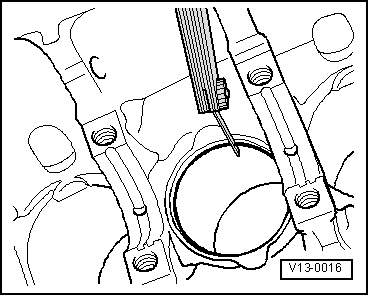

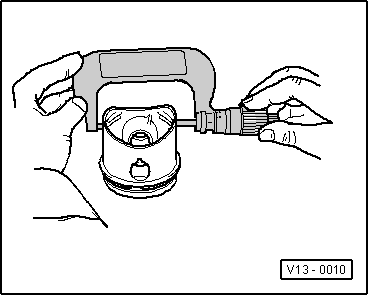

| q | Checking piston ring gap → Fig.. |

| q | Checking ring-to-groove clearance → Fig.. |

| q | 2 or 3 part oil scraper ring, mixed installation permissible |

| 2 - | Piston |

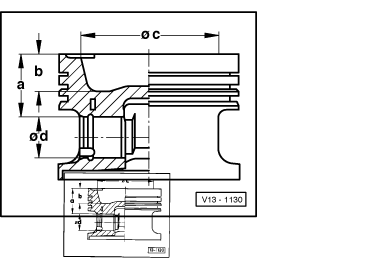

| q | Check → Fig.. |

| q | Mark installation position and cylinder number. |

| q | Arrow on piston crown points to belt pulley end. |

| q | Install using piston ring clamp. |

| q | Characteristics → Fig. |

| 3 - | Conrod |

| q | Renew as set only. |

| q | Mark cylinder number -B-. |

| q | Installation position: Markings -A- face towards belt pulley end. |

| q | For 85 kW engines with oil drilling for piston pin lubrication |

| 4 - | Conrod bearing cap |

| q | Note installation position. |

| 5 - | 30 Nm + 1/4 turn (90 °) further |

| q | Oil threads and contact surface |

| q | To measure radial clearance, tighten to 30 Nm but do not turn further. |

| 6 - | Pressure relief valve, 27 Nm |

| q | For 85 kW engines |

| q | Opening pressure: 2.5…3.2 bar |

| 7 - | Oil spray jet |

| q | For 85 kW engines |

| q | For piston cooling. |

| 8 - | Bearing shell |

| q | Note installation position. |

| q | Do not interchange used bearing shells |

| q | Ensure secure seating in retaining lugs |

| q | Axial clearance new: 0.05…0.31 mm , wear limit: 0.37 mm |

| q | Check radial clearance with Plastigage: new = 0.01…0.06 mm; wear limit = 0.12 mm. Do not rotate crankshaft when checking radial clearance. |

| 9 - | Cylinder block |

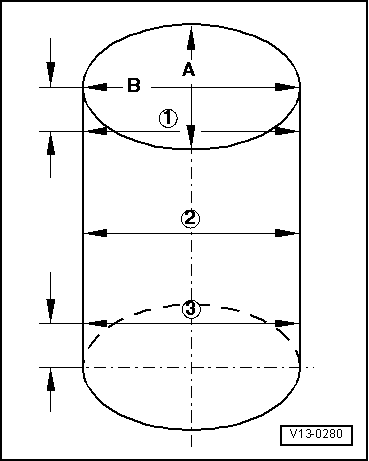

| q | Checking cylinder bore → Fig.. |

| q | Piston and cylinder dimensions → Chapter. |

| 10 - | Conrod bolt |

| 11 - | Circlip |

| 12 - | Piston pin |

| q | If difficult to remove, heat piston to 60 °C. |

| q | Remove and install using drift -VW 222 A- |

|

|

| Piston ring | Ring gap | ||

| New | Wear limit | ||

| Compression rings | mm | 0.20…0.40 | 1.0 |

| Oil scraper ring | mm | 0.25…0.50 | 1.0 |

|

|

| Piston ring | Clearance | ||

| New | Wear limit | ||

| Compression rings | mm | 0.02…0.05 | 0.15 |

| Oil scraper ring | mm | 0.02…0.05 | 0.15 |

|

|

|

|

| Engine codes | AAM and ANN | ABS | ADZ and ANP | |

| Dimension “a” | mm | 22.2 | 22.2 | 22.2 |

| Dimension “b” | mm | 8.1 | 4.4 | 4.4 |

| Recess Ø “c” | mm | 56.8 | 56.0 | 56.0 |

| Piston pin Ø “d” | mm | 20.0 | 20.0 | 20.0 |

| Engine codes | 2E | ADY | AGG and AKR | |

| Dimension “a” | mm | 20.4 | 20.4 | 20.4 |

| Dimension “b” | mm | 5.0 | 5.0 | 5.7 |

| Recess Ø “c” | mm | 64.0 | 64.0 | 64.0 |

| Piston pin Ø “d” | mm | 21.0 | 21.0 | 21.0 |

|

Note

Note