Golf Mk3

| → Indicated on display: |

|

||

|

| → Indicated on display: |

|

||

|

| →

Indicated on display: (1...10 = Display zones) |

|

||

|

The commencement of injection in display zone 2 is dependent on the fuel temperature in display zone 9. |

|

|

|

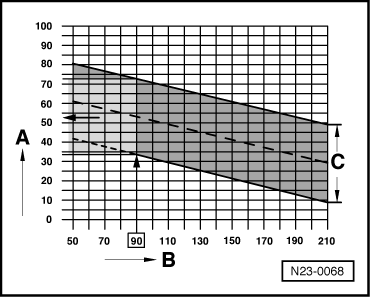

→ Engine codes AFN, AVG, AHU, ALE, 1Z:

Example: The numerical value 90 in display zone 9 (B) corresponds to a numerical value range of 34...73 in display zone 2 (A). |

|

|

|

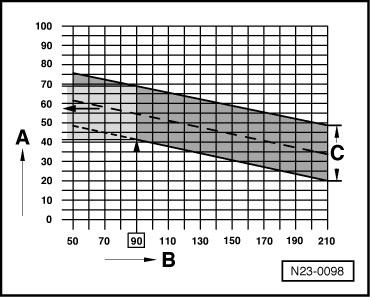

→ Engine code AEY:

Example: The numerical value 90 in display zone 9 (B) corresponds to a numerical value range of 42...69 in display zone 2 (A). Notes:

Note: Loosen and re-tighten (25 Nm) the injection pipes on the injection pump after dynamically adjusting the injection pump. This relieves the strain on pipes and prevents vibration breakages. |