|

1 - Earth (terminal 31)

2 - Exhauster relay -J318-

3 - Fuel cut-off valve N109-

4 - Ecomatic warning lamp -K110-

5 - Generator -K2- and oil pressure -K3- warning lamps

6 - Vacant

7 - Vacant

8 - K-wire for diagnosis

9 - Clutch positioner vacuum valve -N183-

10 - Engine speed sender -G28- (screening)

11 - Clutch movement sender -G162- (wear)

12 - Clutch movement sender -G162- (5 volts)

13 - Gearbox speed sender -G38-

14 - Gearbox speed sender -G38- (input)

15 - Gear recognition switch -F208- (2nd and 5th gear)

16 - Load signal potentiometer -G157- (wear)

17 - Load signal potentiometer -G157- (5 volts)

18 - Gearshift switch -F191-

19 - Clutch system vacuum valve -F210-

20 - Brake light switch -F- (signal)

21 - Door contact switch -F2-

22 - Terminal 15

23 - Terminal 30

|

24 - Priority switching valve -N185-

25 - Starter relay -J53-

26 - Gearshift indicator warning lamp -K48-

27 - Ecomatic automatic override warning lamp -K111-

28 - Steering hydraulics relay -J320-

29 - Speedometer sender -G22-

30 - Diesel engine inhibitor switch -F207-

31 - Clutch positioner vent valve -N184-

32 - Engine speed sender -G28-

33 - Engine speed sender -G28- (input)

34 - Clutch movement sender -G162- earth

35 - Coolant temperature sender -G62-

36 - Gearbox speed sender -G38- (screening)

37 - Gear recognition switch -F208- (1st and 4th gears)

38 - Gear recognition switch -F208- (Neutral and 3rd gear)

39 - Load signal potentiometer -G157- earth

40 - Gear recognition switch (reverse gear) -F208-

41 - Brake servo vacuum switch -F190-

42 - Ecomatic switch -E163-

43 - Gear monitoring switch -F209-

44 - Terminal 50

45 - Terminal 86

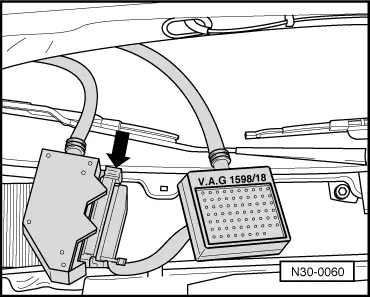

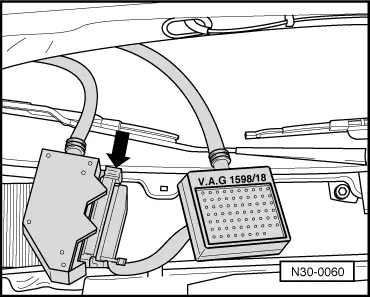

46 - Up to socket 681)

|