Golf Mk3

|

Mono-Motronic injection and ignition system

Checking fuel pressure regulator and holding pressure

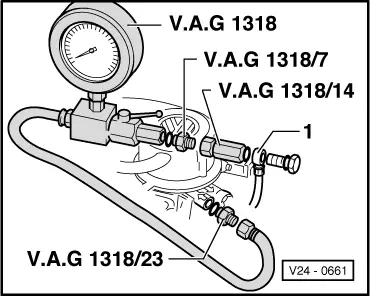

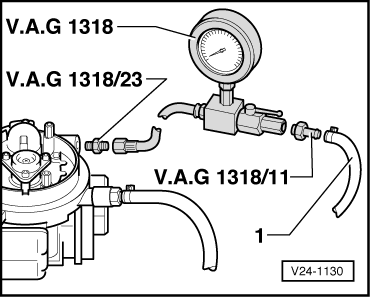

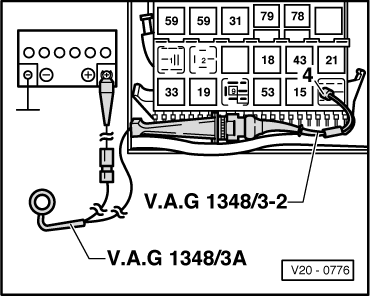

Special tools, testers and auxiliary items

Test conditions

=> Repair group 20; Removing and installing parts of the fuel supply system; Checking fuel pump Test sequence Note: Check whether a coded radio is installed as during the forthcoming work sequences the battery earth strap must be disconnected. Obtain radio code first if necessary. Only for air cleaner on the injection unit (round air cleaner):

|

|

|

|

Warning!

Fuel system is under pressure! Before opening the system place a cloth around the connection. Then release pressure by carefully loosening the connection.

→

Banjo connection |

|

|

|

→

Connect hose directly on connection

|

|

|

|

If the engine does not start:

Note: If the relay cannot be removed from the relay plate without tools then first disconnect battery earth strap.

|

|

|

If the specification is exceeded or not reached:

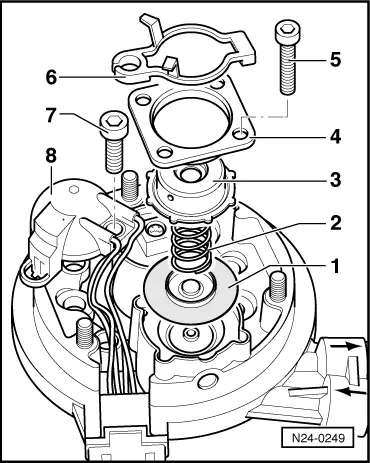

→ Engine code ABD Note: First remove the intake air temperature sender -8- and unclip the cable guide -6-. |

|

|

|

→ Engine code ABU, AEA

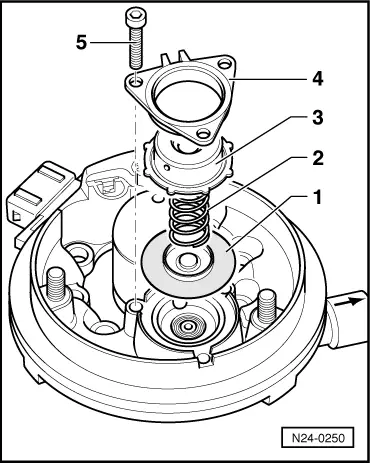

Assembling

Engine code ABD only:

If the specification is again not reached:

If the specification is again exceeded:

If the holding pressure drops below specification:

=> Repair group 20; Removing and installing parts of the fuel supply system; Checking fuel pump If the pressure drops again:

Note: The injection unit upper part and components of the fuel pressure regulator are matched to one another. Therefore individual parts of the pressure regulator must not be exchanged. It is only permissible to dismantle the pressure regulator for cleaning. If the pressure regulator is defective the complete injection unit upper part must be replaced. |