Golf Mk3

|

Checking components

Checking throttle valve control part

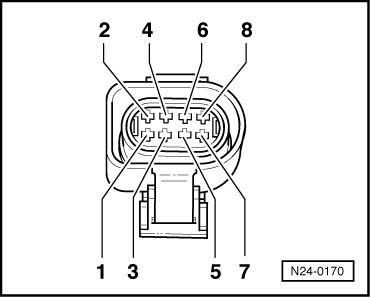

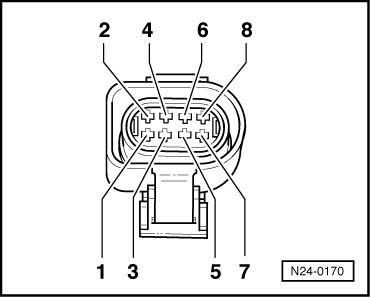

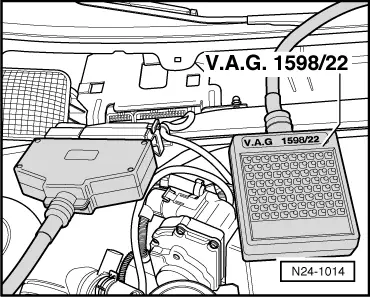

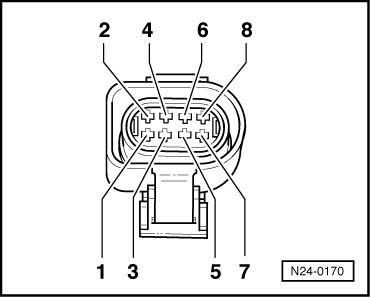

Components of the throttle valve control part (J338): Note: If the throttle valve control part is replaced, the new control part must without fail be adapted to the engine control unit . On vehicles fitted with an automatic gearbox the gearbox control unit must also be adapted: Special tools, workshop equipment, testers, measuring instruments and auxiliary items required

Test conditions

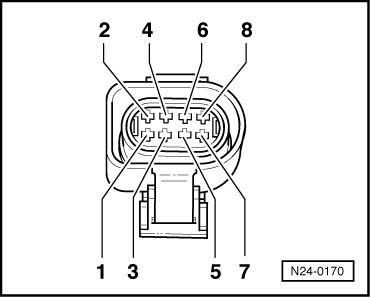

Checking idling switch (F60)

|

| → Indicated on display: |

|

||

|

| → Indicated on display: |

|

||

|

|

→

Indicated on display: (1...4 = Display zones) |

|

|||||||||

Display constantly remains on one operating condition:

|

|

|

|

Continuation of check when display shows part throttle

If display jumps to idling:

If display remains on idling:

If the voltage supply and wiring is OK:

Continuation of check when display constantly shows idling |

|

|

If display jumps to part throttle:

If display remains on part throttle:

If the voltage supply and wiring is OK:

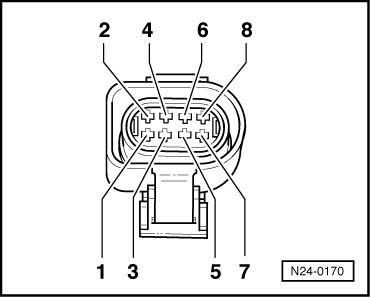

Checking throttle valve drive (G186) and throttle valve drive angle sender (G187) Test conditions

Test sequence

|

| → Indicated on display: |

|

||

|

| → Indicated on display: |

|

||

|

|

→

Indicated on display: (1...4 = Display zones) |

|

||

If the specifications are not attained:

|

|

|

If the specification is not obtained:

If the specification is obtained:

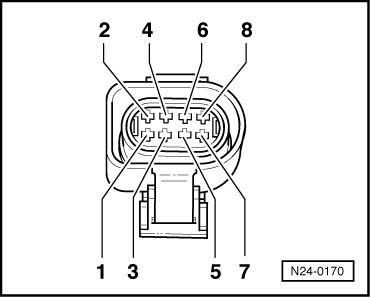

Checking throttle valve potentiometer (G69) Test sequence

|

| → Indicated on display: |

|

||

|

| → Indicated on display: |

|

||

|

|

→

Indicated on display: (1...4 = Display zones) |

|

|||||||||

Note: The displayed figure is dependent on the tolerances of the throttle valve potentiometer and does not correspond to the actual opening angle. If the figure does not increase uniformly:

If the display constantly shows 0 <° or is above 90 <°:

Continuation of check when display 0 <°: |

|

|

If display jumps above 90 <°:

If display remains at 0 <°:

If the voltage supply and wiring is OK:

Continuation of check when display is above 90 <°: |

|

|

If display jumps to 0 <°:

If display remains above 90 <°:

If the voltage supply and wiring is OK:

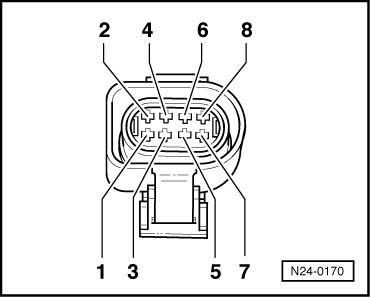

Checking voltage supply and wiring to control unit |

|

|

|

|

|

If the specifications are not attained:

|

|

|

If no fault is detected in the wiring:

|