Golf Mk3

|

Motronic injection and ignition system

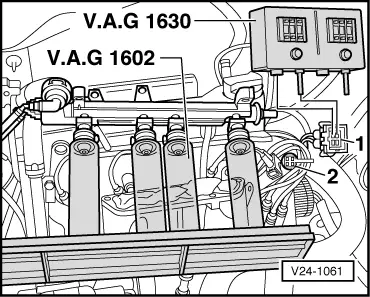

Checking injectors

Special tools, testers and auxiliary items

Checking resistance and voltage supply Test conditions

Test sequence

If electrical check specifications are attained:

|

| → Indicated on display: |

|

||

|

| → Indicated on display: |

|

||

|

Note: If something different is indicated on the display: => Fault reader operating instructions

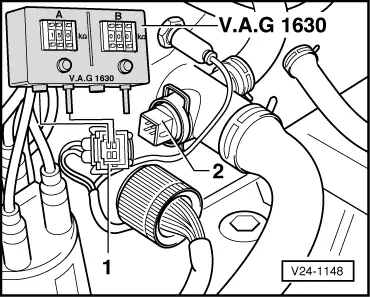

Activate Cyl. 1 injector (N30):

|

| → Indicated on display: |

|

||

The LED flashes: The LED does not flash: To activate injectors, Cyls. 2...4 in each case:

If the electrical check specifications are not attained:

If the specifications are not attained: If the specifications are attained:

Checking spray pattern and for leaks Test conditions

Test sequence |

|

|

|

|

|

Note: When installing the injectors ensure that the O-rings are not/will not be damaged. To facilitate installation, moisten O-rings slightly with oil.

|