Golf Mk3

| → Indicated on display: |

|

||

|

| → Indicated on display: |

|

||

|

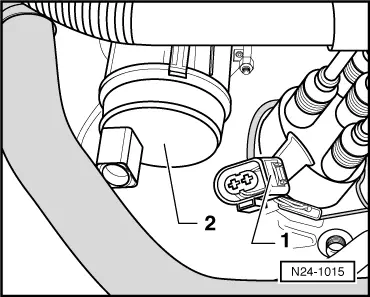

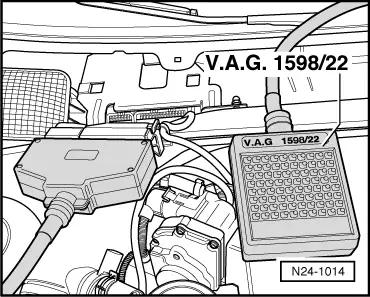

Activate injectors (N30...N33):

|

| → Indicated on display: |

|

||

|

Note: The fuel pump must run and the flow noise must be distinctly audible at the fuel pressure regulator. If the fuel pump does not run, check activation. => Repair group 20; Removing and installing parts of the fuel system; Checking fuel pump

If one of the injectors is not activated (does not click):

Activating activated charcoal filter solenoid valve 1 (N80):

|

| → Indicated on display: |

|

||

If the solenoid valve does not click: |

|

|

LED flashes:

LED does not flash:

|

|

|

If no wiring fault is detected:

Activating secondary air inlet valve (N112):

Note: On vehicles 05.00 ▸the secondary air inlet valve has been discontinued, but still exists in the test sequence for the final control diagnosis. Ignore the display on these vehicles and press ⇒ key again. |

| → Indicated on display: |

|

||

If the valve does not click: |

|

|

LED flashes:

=> Repair group 26; Secondary air system; Removing and installing parts of the secondary air system LED does not flash:

|

|

|

If no wiring fault is detected:

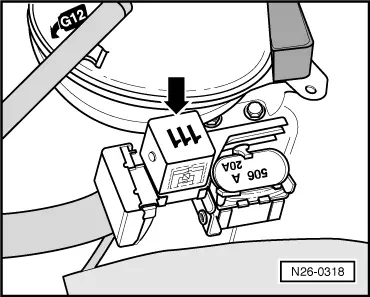

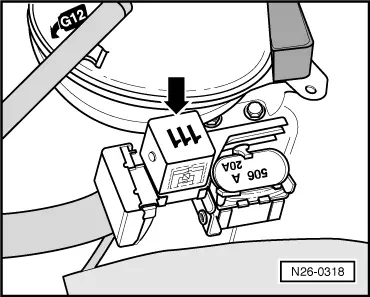

Activating secondary air pump relay (J299):

|

| → Indicated on display: |

|

||

If the secondary air pump motor (V101) does not run at intervals: |

|

|

LED flashes:

=> Repair group 26; Secondary air system; Removing and installing parts of secondary air system If the LED does not flash but the secondary air pump relay clicks:

If no wiring fault is detected: |

|

|

Notes:

If no wiring fault is detected:

If voltage supply is OK:

If the LED does not flash and the secondary air pump relay does not click:

|

|

|

Notes:

LED flashes:

LED does not flash:

LED does not light-up: |

|

|

LED lights up:

If no wiring fault is detected:

|

| → Indicated on display: |

|

||

Note: After completion of the final control diagnosis switch off ignition. If the ignition is not switched off before attempting to start, the engine will not start, as the injectors and the ignition transformer will not be activated. |