Golf Mk3

|

|

Checking voltage supply

|

|

|

If the specifications are not attained:

|

|

|

If no wiring fault is detected:

Checking idling switch

|

| → Indicated on display: |

|

||

|

| → Indicated on display: |

|

||

|

|

|

If the specifications are not obtained: |

|

|

If no wiring fault is detected:

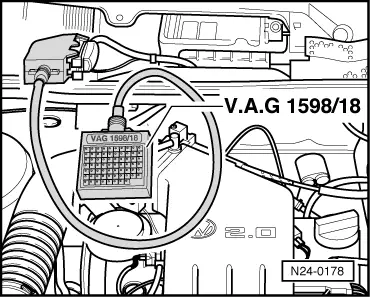

Checking throttle valve positioner and throttle valve positioner potentiometer Test conditions

Test sequence

|

| → Indicated on display: |

|

||

|

| → Indicated on display: |

|

||

|

| →

Indicated on display: (1...4 = Display zones) |

|

||||||||||||||||||||||||||||||||||||||||

1) Up-to-date specifications: => Exhaust emissions test binder

| |||||||||||||||||||||||||||||||||||||||||

| →

Indicated on display: (1...4 = Display zones) |

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1) On vehicles with manual gearbox '0' is always displayed. Evaluating display group 37

1) Value remains constant also at longer idling phase. Evaluating display group 36

Continuation | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

If the specification is not obtained: |

|

|

If the specifications are again not attained:

If the specification is attained:

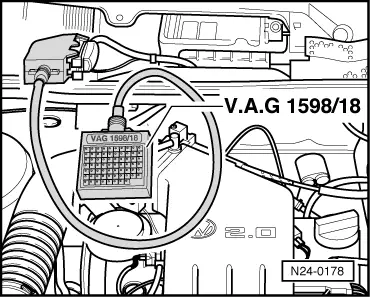

Checking throttle valve potentiometer

|

| → Indicated on display: |

|

||

|

| → Indicated on display: |

|

||

|

| →

Indicated on display: (1...4 = Display zones) |

|

||||||||||||||||||||||||||||||||||||||||||||||||||||

Note: The displayed figure is dependent on the tolerances of the throttle valve potentiometer and does not correspond to the actual opening angle. The maximum permissible displayed figure is 90.0 <°. If the figure does not increase uniformly:

Evaluating display group 3

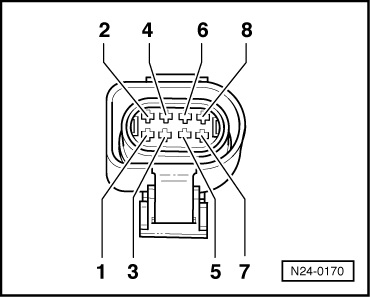

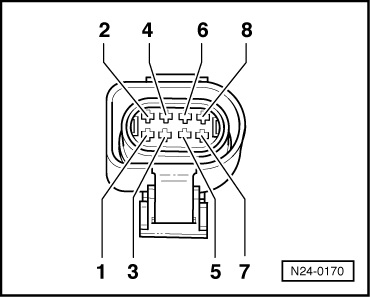

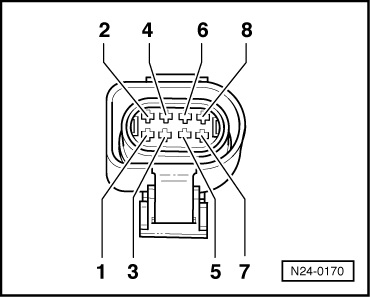

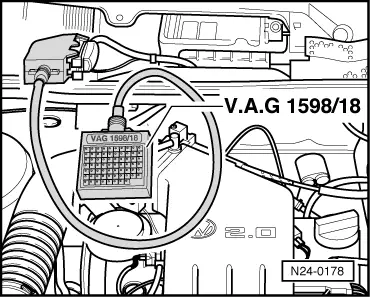

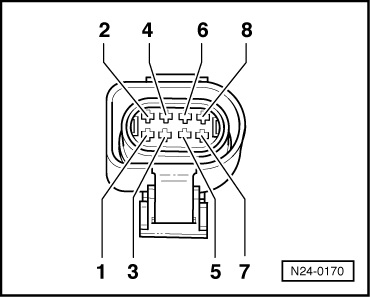

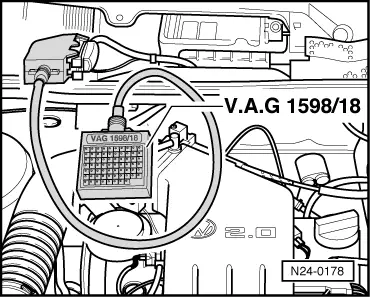

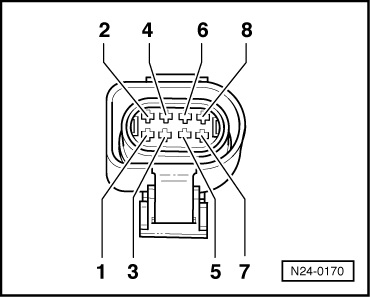

Check wiring | |||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

|

|

Continuation if voltage is present: If voltage of about 5 V was present:

If the voltage was approx. battery voltage:

Continuation if no voltage is present:

If no wiring fault is detected:

|