Golf Mk3

| Repairing rear brakes |

Note

Note| t | After working on the rear wheel brakes: |

| t | Release handbrake. |

| t | Firmly depress brake pedal once. |

| 1 - | Spring plate |

| q | To remove, push against the spring and turn through 90°. |

| 2 - | Spring |

| 3 - | Brake shoe with lever for handbrake |

| q | Removing and installing → Chapter. |

| q | Adjust handbrake → Chapter. |

| 4 - | Upper return spring |

| q | Unhook with spring pliers. |

| 5 - | Lower return spring |

| q | Grease contact points with lubricating paste -G 000 650-. |

| 6 - | Spring |

| 7 - | Brake shoes |

| q | Removing and installing → Chapter. |

| q | Minimum lining thickness 2.5 mm |

| 8 - | Slides |

| 9 - | Brake carrier |

| q | For vehicles with four-wheel drive. |

| 10 - | Cap |

| q | Remove to check brake pad thickness. |

| 11 - | Shoe steady pin |

| 12 - | Brake carrier |

| 13 - | Hexagon socket head bolt, 10 Nm |

| q | Checking for leaks → Fig.. |

| q | Aluminium wheel brake cylinders are secured with just one bolt. |

| q | Aluminium wheel brake cylinders can be retrofitted. |

| q | Mixed installation is permissible. |

| 14 - | Wheel brake cylinder |

| 15 - | Wedge |

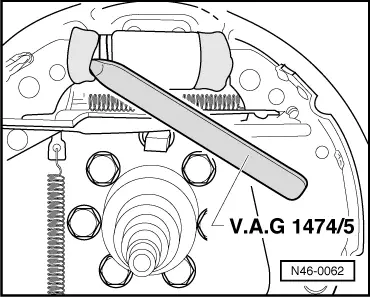

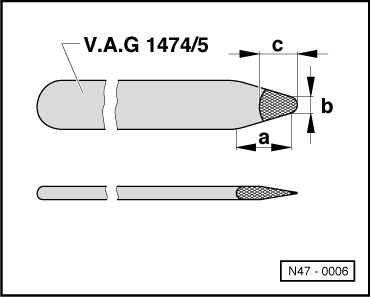

| q | To remove and install the brake drum, push upwards through a wheel bolt hole ⇒ Page → Chapter |

| 16 - | Push rod |

| q | Grease contact points with lubricating paste -G 000 650-. |

| 17 - | Locating spring |

| q | Unhook with spring pliers. |

|

|