| –

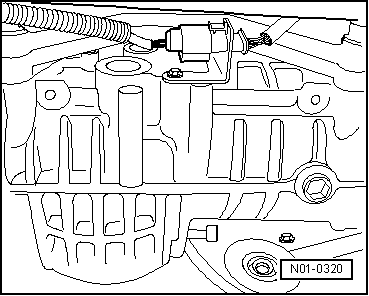

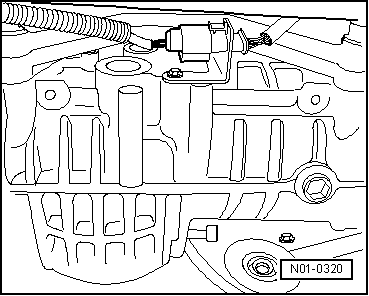

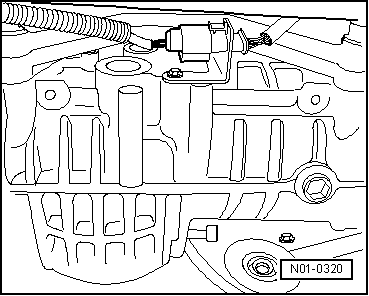

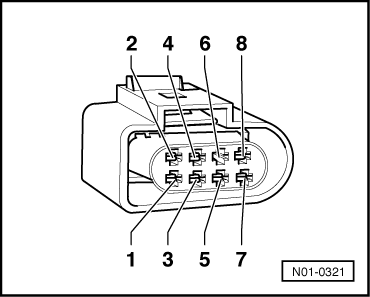

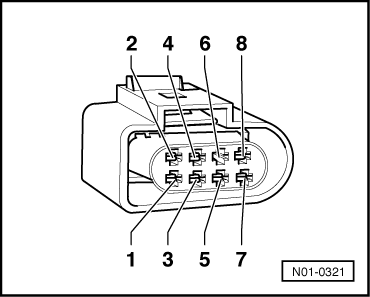

| Join connector for four-wheel drive control unit -J492-. |

| –

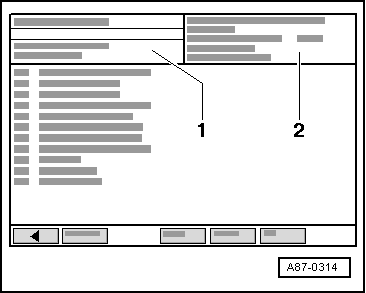

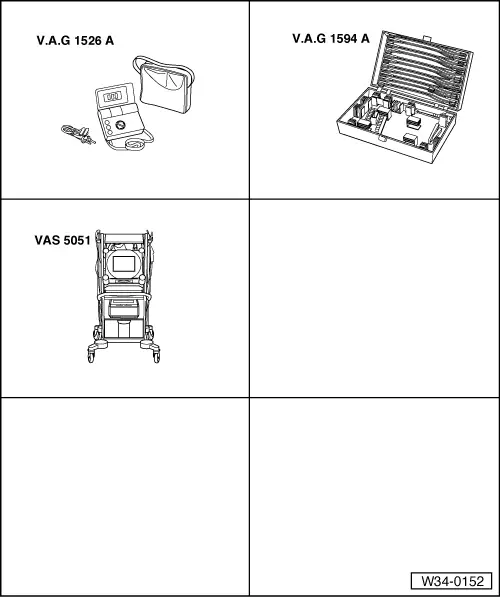

| Connect vehicle diagnosis, testing and information system -VAS 5051- → Chapter. |

| –

| Operate clutch pedal and engage 1st gear. |

| –

| Drive off slowly, whereby it must be observed that rear wheels attempt to drive against handbrake. |

Note | Release clutch slowly or engine will stall. |

| If it is not observed that rear wheels attempt to drive against handbrake |

| t

| If no fault could be found, then oil pressure control motor -V184- is defective. |

Note | The oil pressure control motor -V184- is integrated in the four-wheel drive control unit. |

| If it is observed that rear wheels attempt to drive against handbrake |

| –

| Operate clutch pedal and select vehicle system “03 - Brake electronics” on -VAS 5051-. |

|

|

|

Note

Note

Note

Note Note

Note