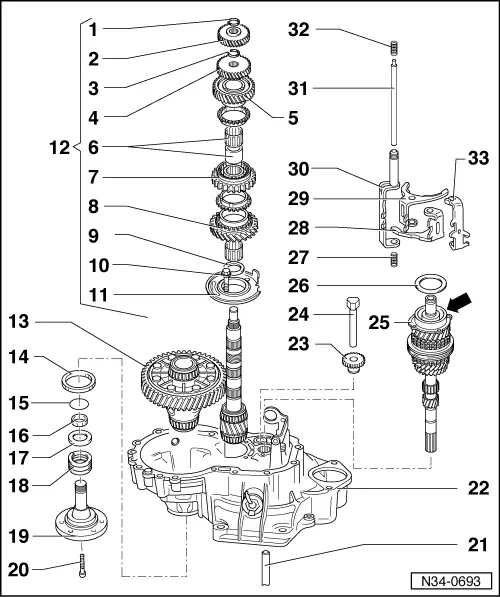

Golf Mk4

| Dismantling and assembling input shaft, output shaft, differential and selector forks |

| 1 - | Retaining ring |

| q | Always renew |

| 2 - | Gear wheel for 4th gear |

| q | Installation position → Chapter |

| 3 - | Retaining ring |

| q | Gear wheel for 3rd gear |

| q | Redetermining thickness → Chapter |

| 4 - | Gear wheel for 3rd gear |

| q | Installation position → Chapter |

| q | Adjusting axial play → Chapter. |

| 5 - | Synchromeshed gear for 2nd gear |

| 6 - | Needle bearing |

| q | For 2nd gear |

| q | Pulling off inner race → Chapter. |

| q | Pressing on inner race → Chapter. |

| 7 - | Locking collar with synchro-hub for 1st and 2nd gears |

| 8 - | Synchromeshed gear for 1st gear |

| 9 - | Thrust washer |

| q | Installation position → Chapter |

| 10 - | Hexagon bolt, 25 Nm and turn 90° further |

| 11 - | Bearing support |

| q | With large tapered roller bearing outer race and stop for reverse gear wheel. |

| 12 - | Output shaft, complete |

| q | Dismantling and assembling → Chapter |

| 13 - | Differential |

| q | Dismantling and assembling → Chapter |

| 14 - | Seal |

| q | Renewing → Chapter |

| 15 - | Retaining ring |

| q | Holds tapered ring, thrust washer and spring in position when flange shaft is removed. |

| 16 - | Tapered ring |

| q | With grooves to engage in thrust washer |

| q | Installation position: taper towards differential cage |

| 17 - | Thrust washer |

| q | Installation position: shoulder faces spring, lugs face tapered ring |

| 18 - | Compression spring |

| 19 - | Flange shaft |

| q | Removing and installing → Chapter |

| 20 - | Hexagon socket head bolt, 25 Nm |

| 21 - | Clutch push rod |

| 22 - | Clutch housing |

| q | Repairing → Chapter |

| 23 - | Reverse gear |

| 24 - | Reverse gear shaft |

| 25 - | Input shaft |

| q | Dismantling and assembling → Chapter |

| q | Press off deep groove ball bearing -arrow- before installing → Chapter. |

| q | Install new deep groove ball bearing in gearbox housing → Chapter. |

| 26 - | Shim |

| q | It is not necessary to adjust input shaft. It is important, however, that shim of the thickness determined during production is installed after repairs are completed. It is possible that no shim is installed. The reassemble without shim. When replacing bearing or clutch housing or gearbox housing, it is no longer necessary to insert shim. |

| 27 - | Compression spring |

| 28 - | Selector fork for 1st and 2nd gears |

| 29 - | Selector fork for 3rd and 4th gears |

| 30 - | Selector bridge with selector tube for 5th gear |

| 31 - | Selector rod |

| 32 - | Compression spring |

| 33 - | Selector fork for reverse gear |