Golf Mk4

|

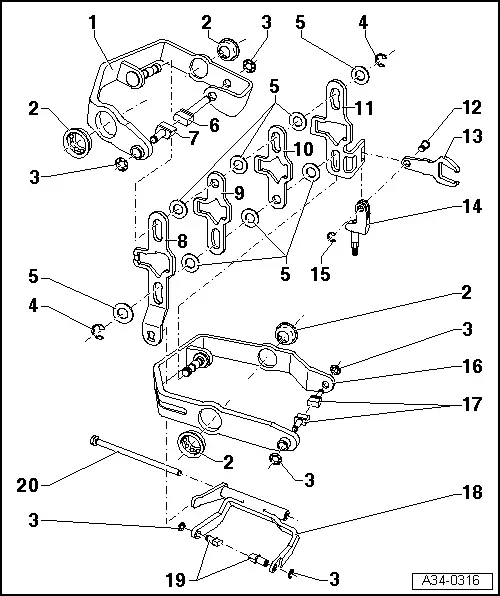

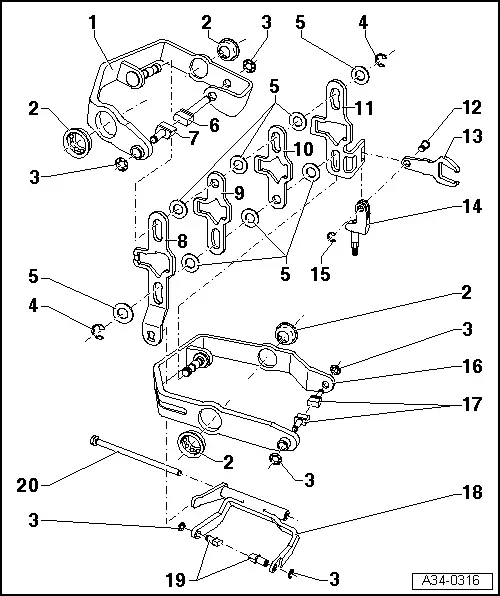

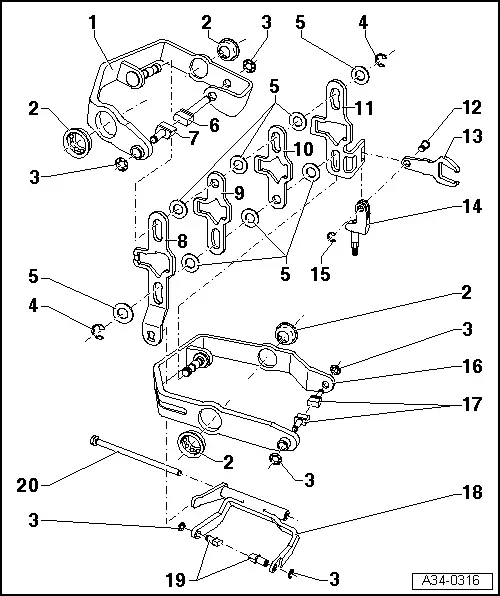

Dismantling and assembling selector forks

Dismantling and assembling selector forks

|

|

|

|

|

|

|

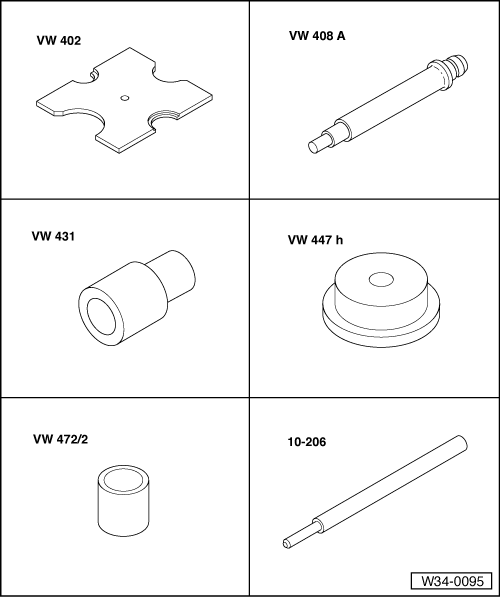

Notes: |

|

|

|

|

|

|

|

|

|

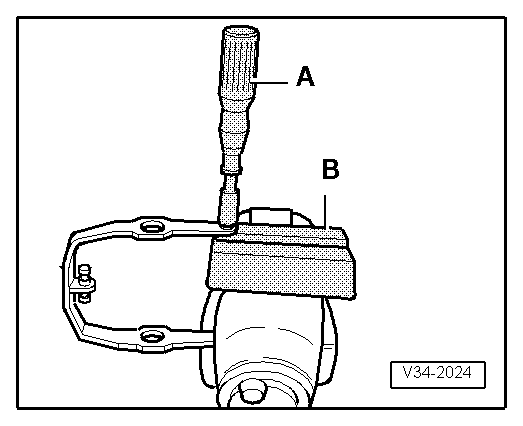

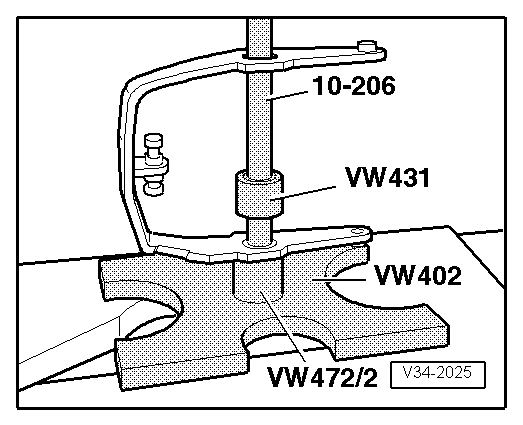

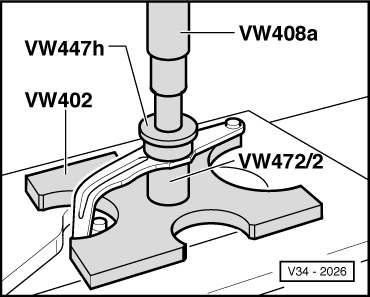

→ Fig.1 Removing angular contact ball bearing Note: When removing and installing the inner races, do not bend selector forks. |

|

|

|

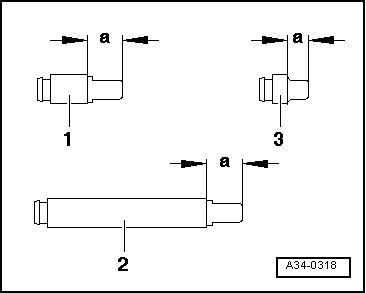

→ Fig.2 Pressing in angular contact ball bearing onto stop |

|

|

|

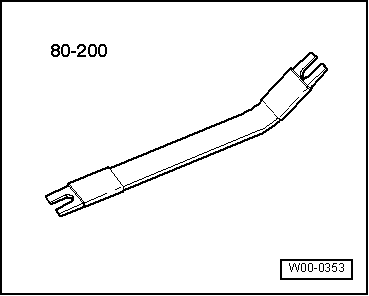

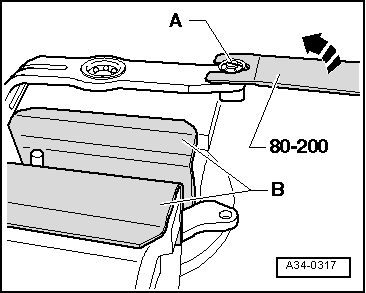

→ Fig.3 Removing lock washer

|