Golf Mk4

|

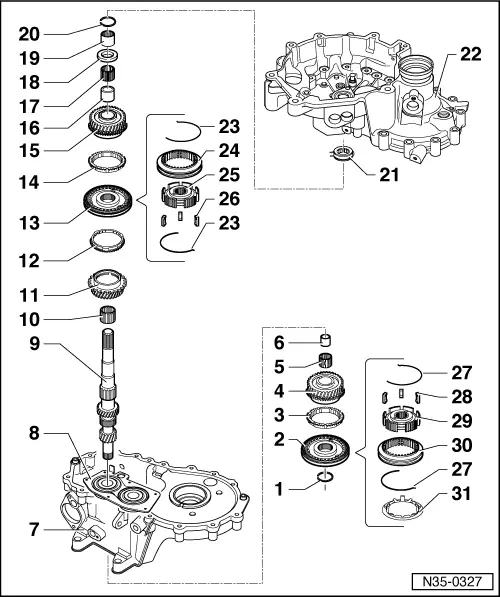

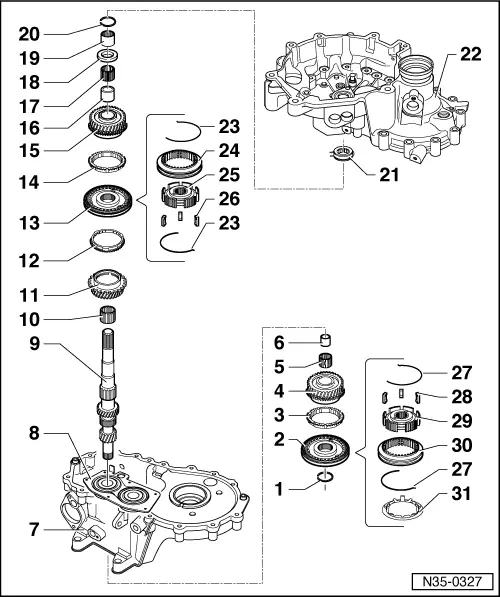

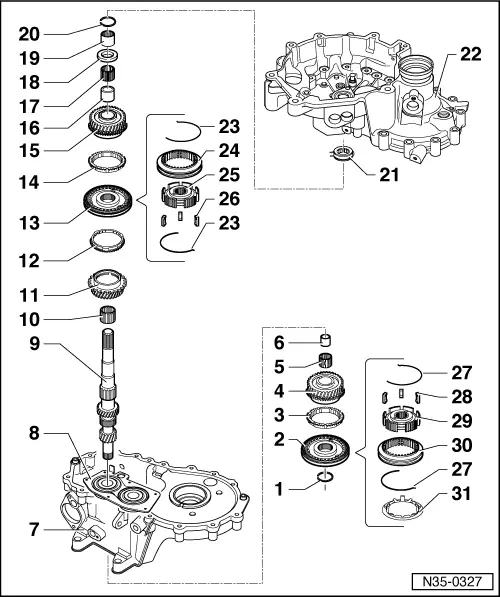

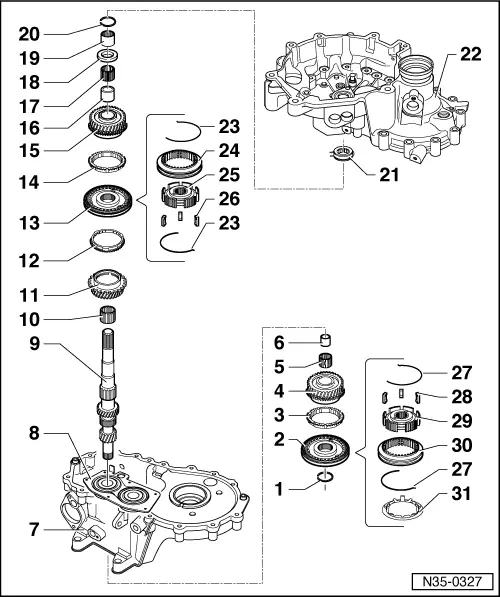

Dismantling and assembling input shaft

Dismantling and assembling input shaft

|

|

|

|

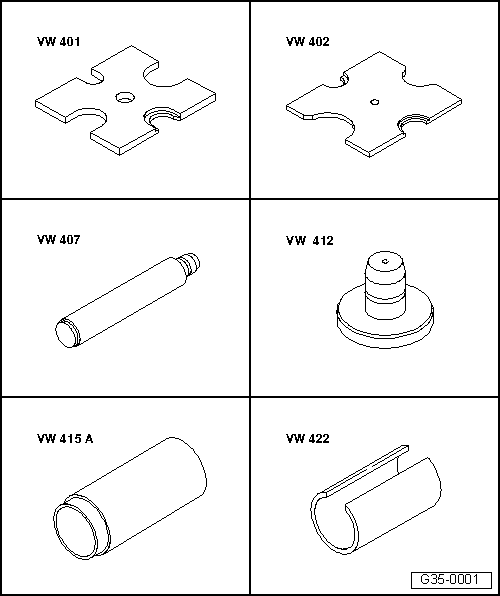

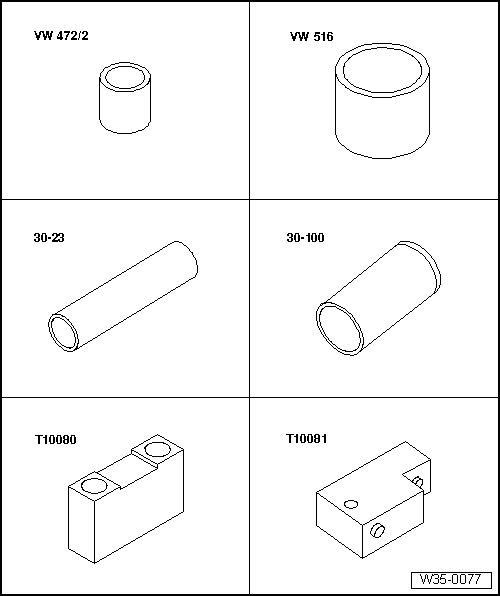

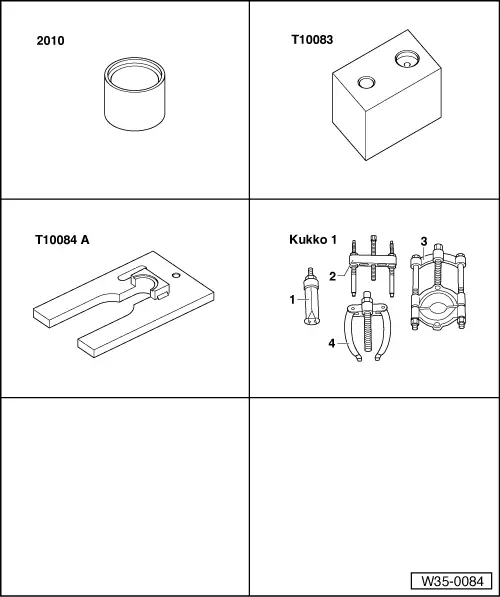

Special tools, workshop equipment, test and measuring appliances and auxiliary items required

|

|

|

|

Special tools, workshop equipment, test and measuring appliances and auxiliary items required

|

|

|

|

Notes:

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

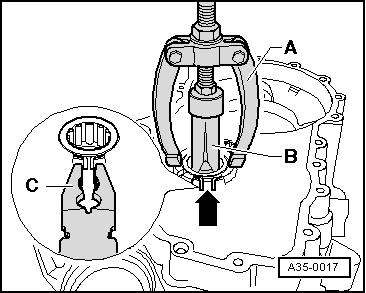

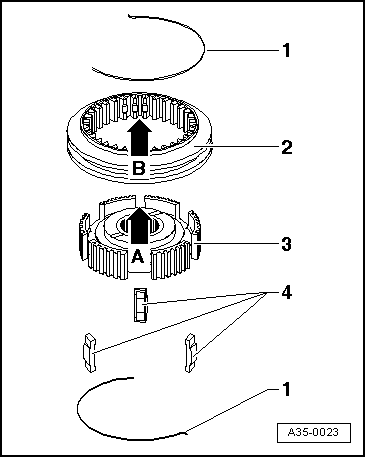

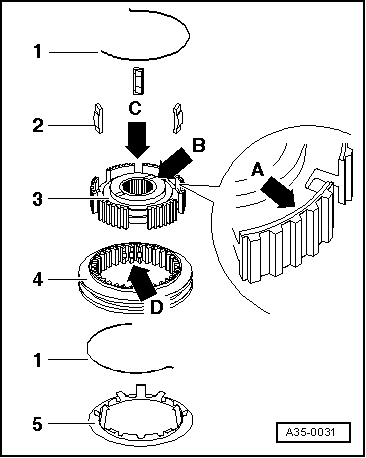

→ Fig.7 Installation position 3rd and 4th gear locking collar/synchro-hub The groove on the top (arrow B) points towards 4th gear. |

|

|||||||

|

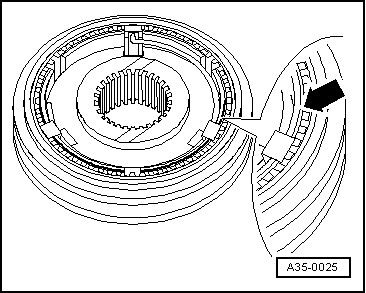

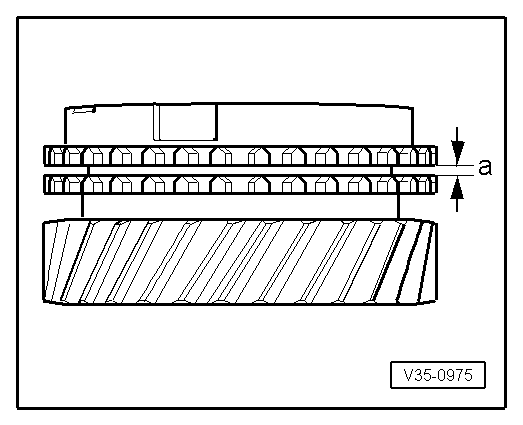

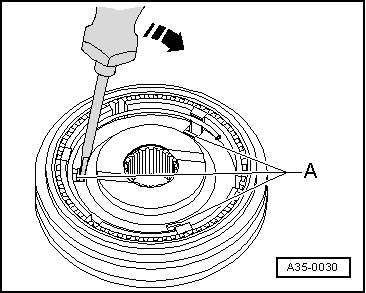

→ Fig.8 Checking synchro-ring for wear

|

|

|

|

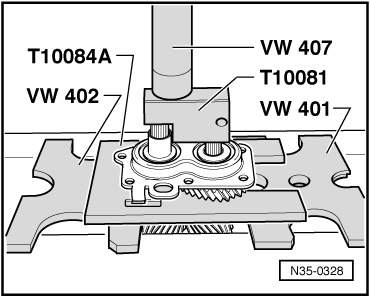

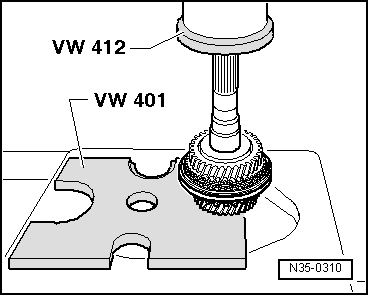

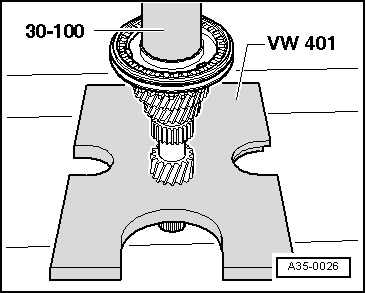

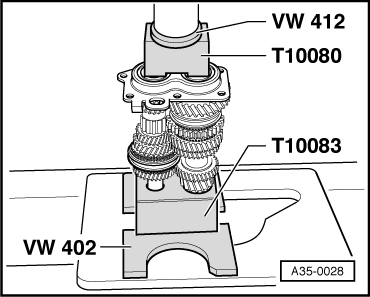

→ Fig.9 Pressing on 3rd and 4th gear synchro-hub and locking collar |

|

|

|

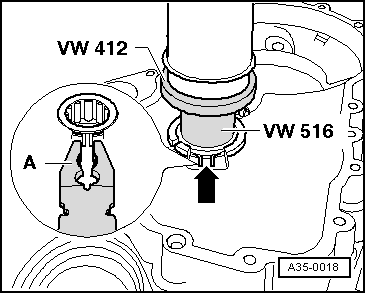

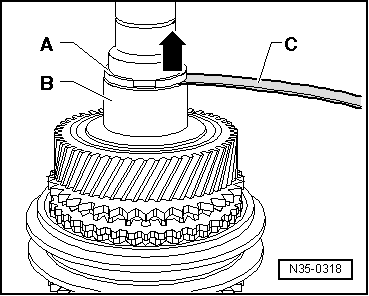

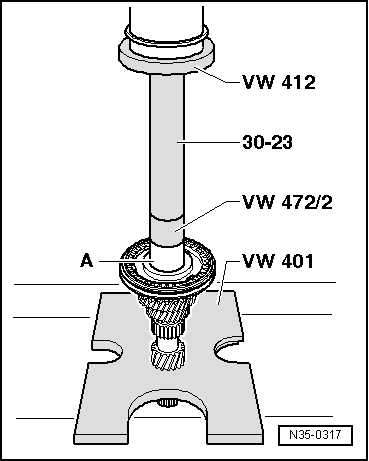

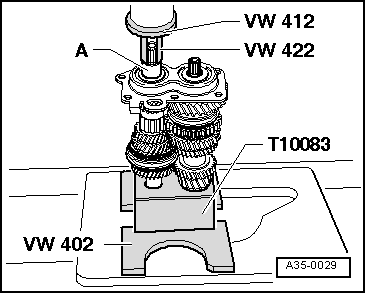

→ Fig.10 Pressing on sleeve -A- for 4th gear needle roller bearing

|

|

|

|

→ Fig.11 Pressing on roller bearing inner race -A- |

|

|

|

→ Fig.13 Pressing on bearing mounting with grooved ball bearings

Warning!

Wear protective gloves! |

|

|

|

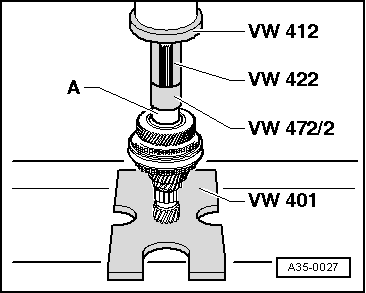

→ Fig.14 Pressing on sleeve -A- for 5th gear needle roller bearing |

|

|

|

→ Fig.15 Removing thrust ring

|

|

|

|

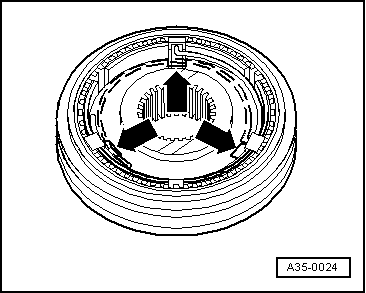

→ Fig.16 Dismantling and assembling 5th gear locking collar and synchro-hub

The deeper recesses -arrow C- for the locking pieces in the synchro-hub must align with the recesses -arrow D- in the locking collar. |

|

|

|

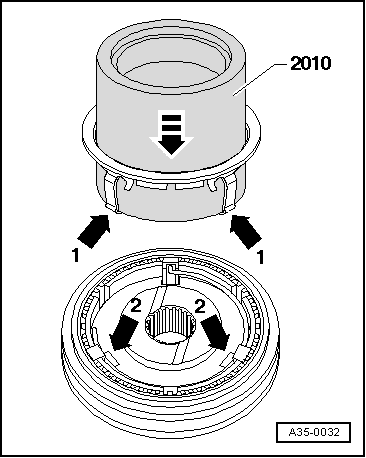

→ Fig.17 Assembling 5th gear locking collar/synchro-hub

|

|

|

|

→ Fig.18 Installing check ring

|