Golf Mk4

|

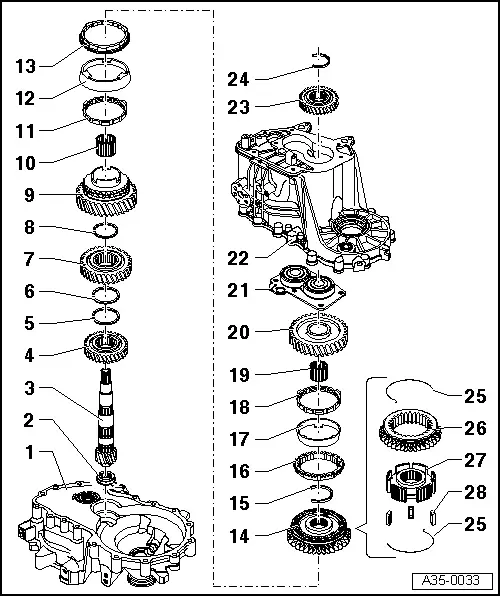

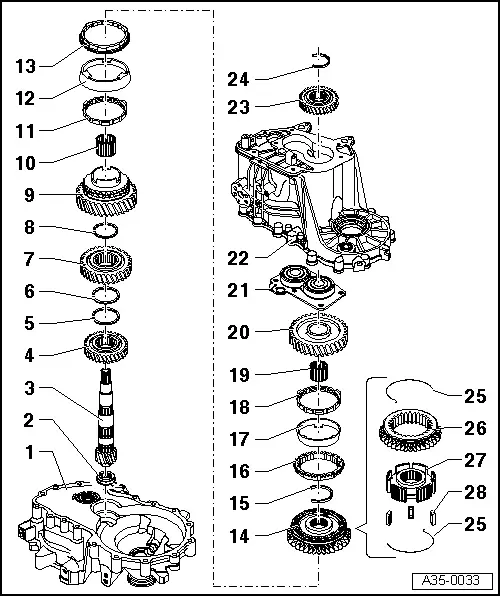

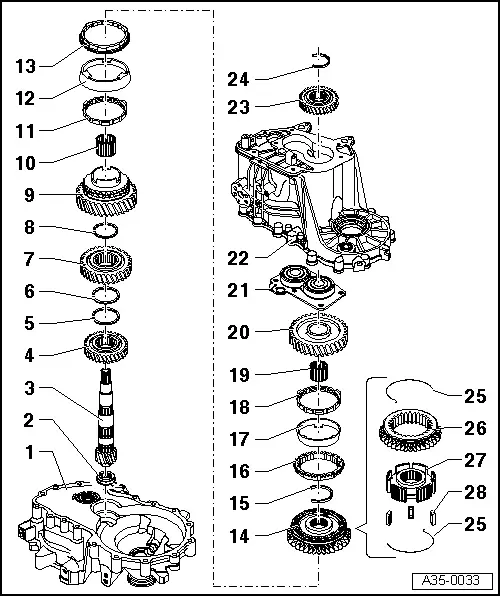

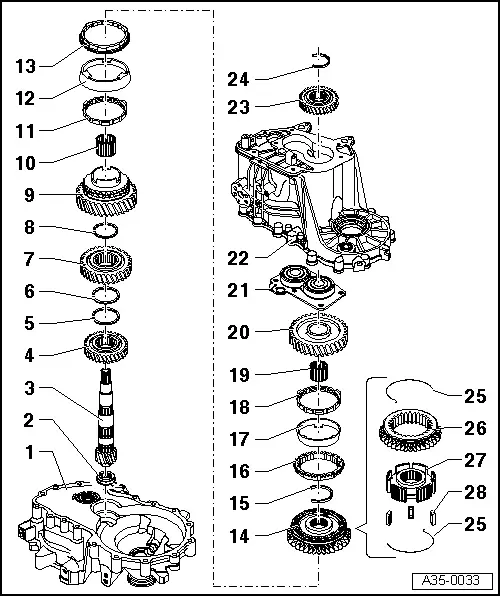

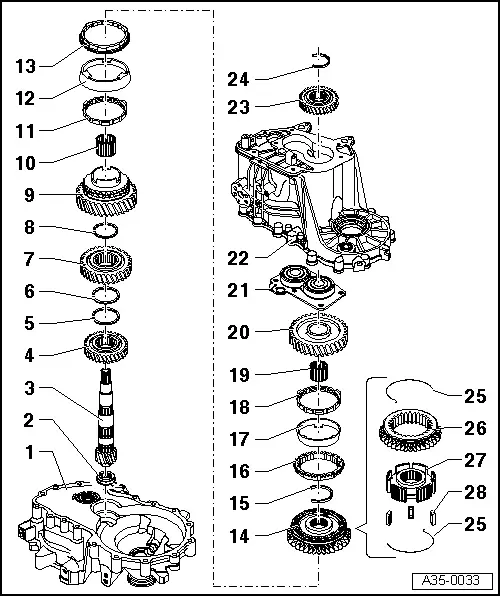

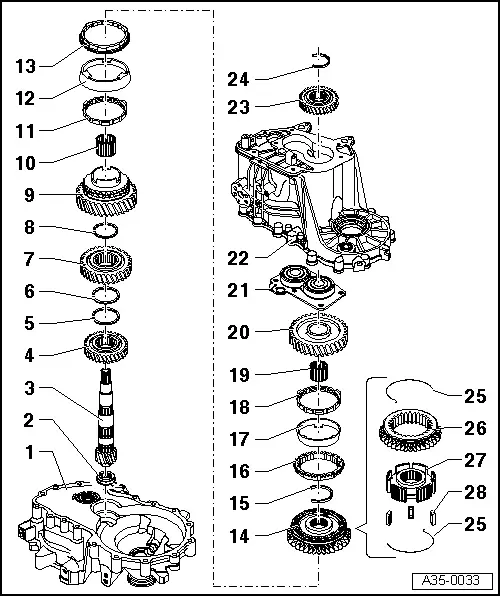

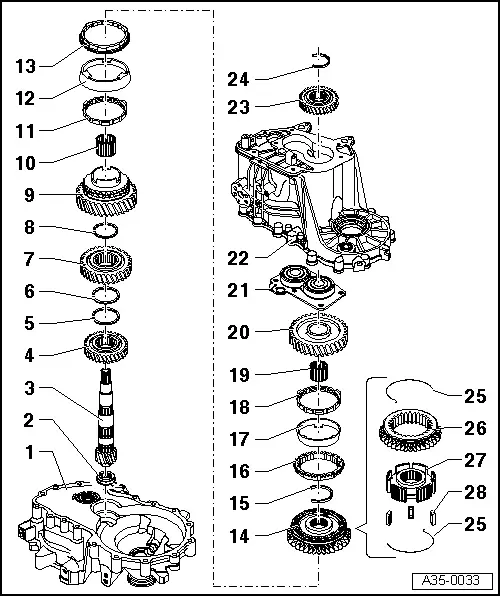

Dismantling and assembling output shaft

Dismantling and assembling output shaft

|

|

|

|

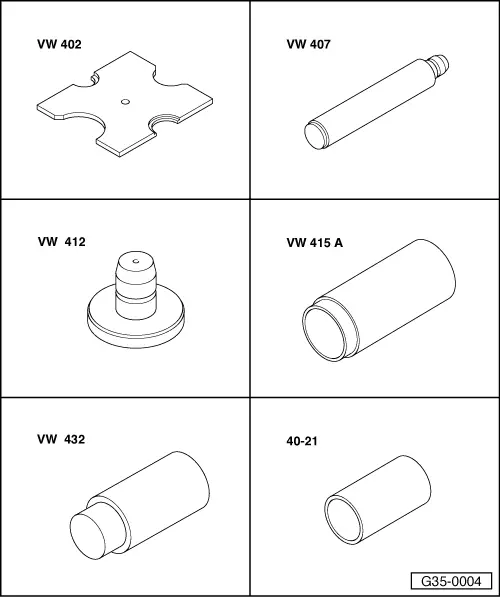

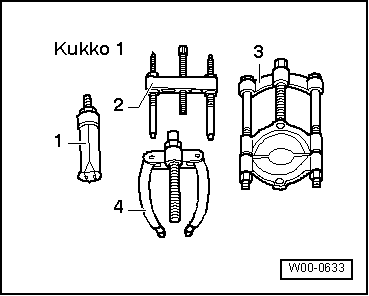

Special tools, workshop equipment, testers, measuring instruments and auxiliary items required

|

|

|

|

Notes:

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

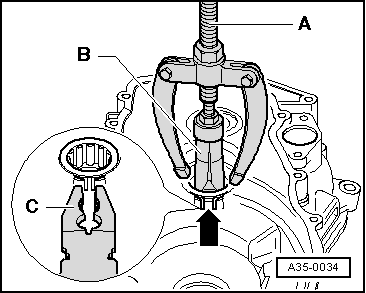

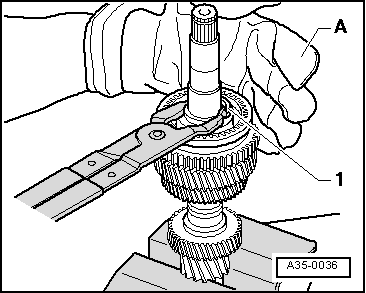

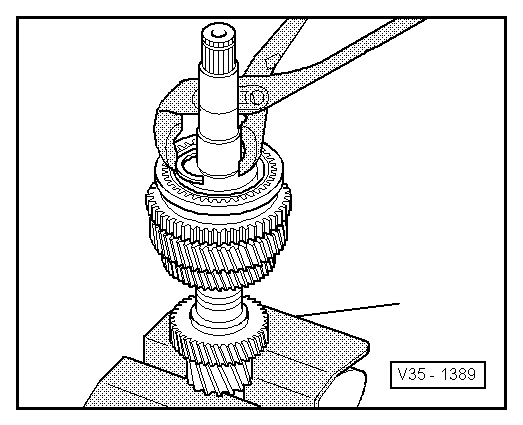

→ Fig.3 Removing circlip -1- from groove

Warning!

Prevent circlip from springing off uncontrolled. |

|

|

|

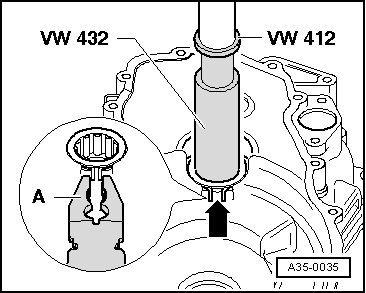

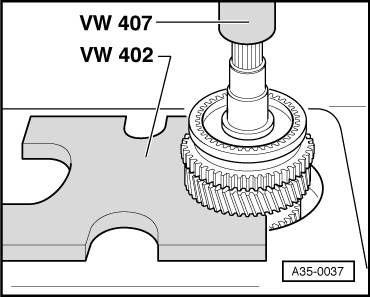

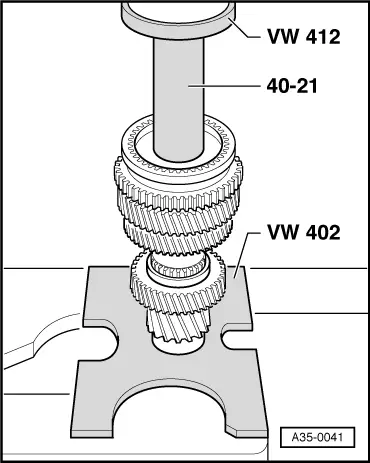

→ Fig.4 Pressing off 1st and 2nd gear locking collar/synchro-hub

|

|

|||||||

|

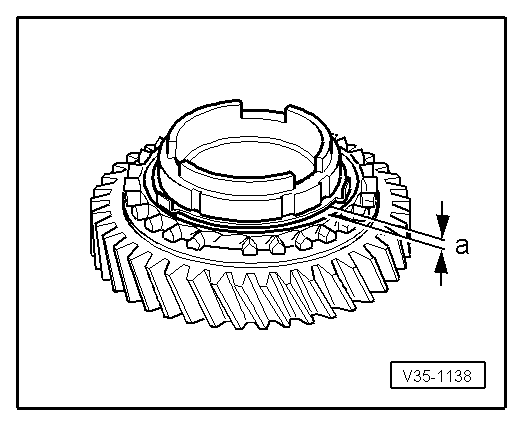

→ Fig.7 Checking 1st and 2nd gear synchro-ring for wear

|

|

|

|

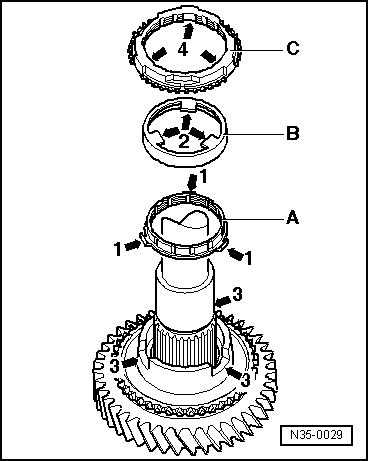

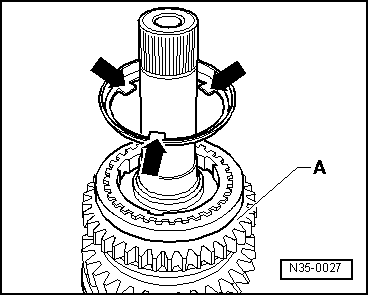

→ Fig.8 Installation position of outer ring, inner ring and synchro-ring of 2nd gear

|

|

|

|

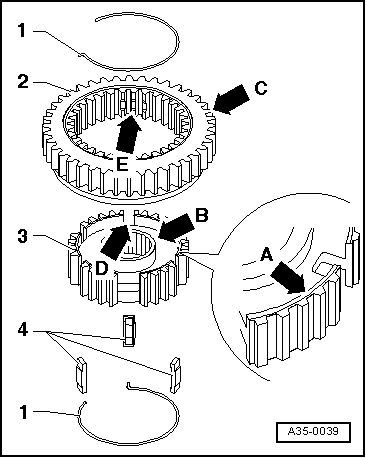

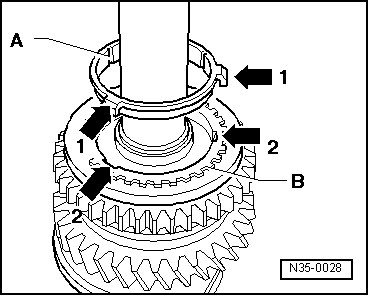

→ Fig.9 Dismantling and assembling 1st and 2nd gear locking collar and synchro-hub

Installation position: The groove on the top -arrow A- and the higher collar -arrow B- of the synchro-hub face the gear teeth of the locking collar when fitted together -arrow C-. The deeper recesses -arrow D- for the locking pieces in the synchro-hub must align with the recesses -arrow E- in the locking collar. |

|

|

|

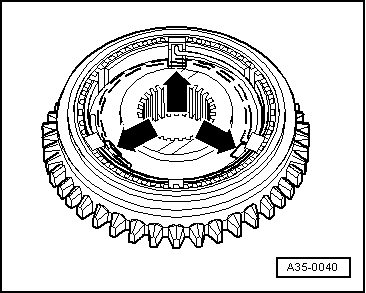

→ Fig.10 Assembling 1st and 2nd gear locking collar/synchro-hub

|

|

|

|

→ Fig.11 Pressing on 1st and 2nd gear locking collar/synchro-hub Installation position: The groove in the locking collar for the selector fork faces the 1st gear and the reverse gear teeth face the 2nd gear.

|

|

|

|

→ Fig.12 Inserting circlip

|

|

|

|

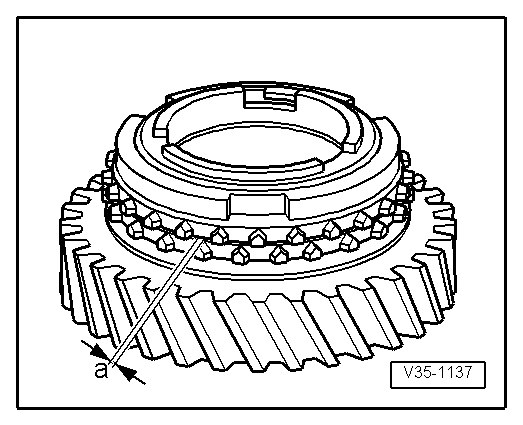

→ Fig.13 Installation position for 1st gear outer ring The lugs (arrows) face the gear teeth of the reverse gear |

|

|

|

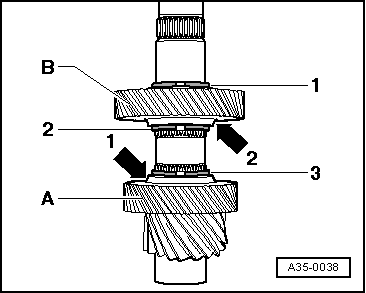

→ Fig.14 Installation position of 1st gear inner ring -A- The lugs (arrow 1) locate in the recesses (arrow 2) in the synchro-ring -B-. |

|

|

|

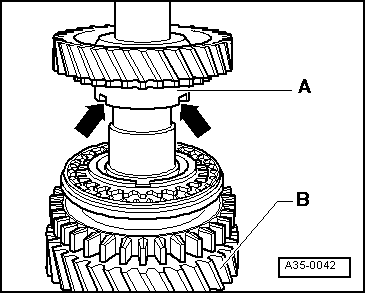

→ Fig.15 Installation position of selector gear for 1st gear The higher collar -A- faces the 2nd gear -B-. The recesses in the collar (arrows) locate with the tabs of the outer ring (arrow => Fig.13 ) |