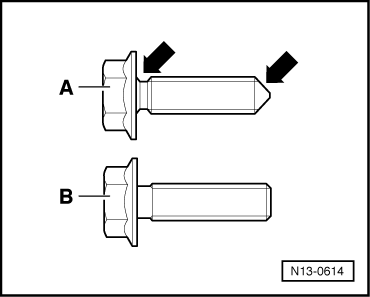

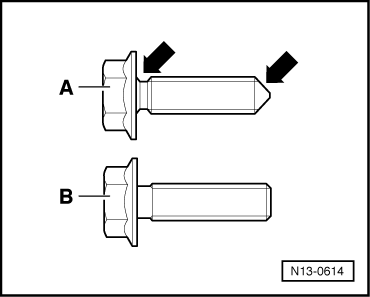

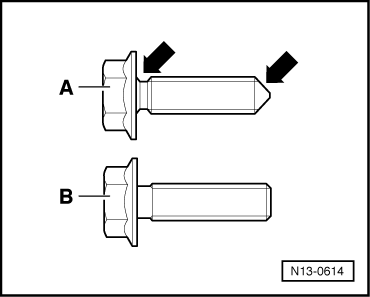

| Type -A-: securing bolts with milled neck and tapered end -arrow- |

| –

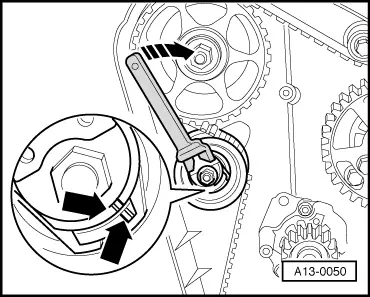

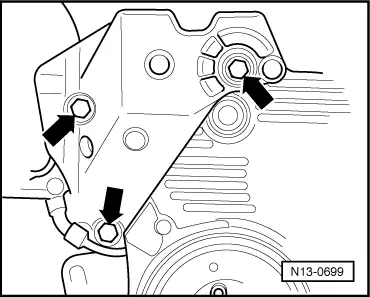

| Tighten new securing bolts of injection pump belt pulley. Specified torque: 20 Nm. |

Note | t

| Following dynamic check of commencement of injection, securing bolts should be tightened further by 90° (1/4 turn). |

| t

| The securing bolts should only be used once as these are stretch bolts. |

| Type -B-: securing bolts without milled neck and with flat end |

| –

| Tighten old securing bolts of injection pump belt pulley. Torque setting: 25 Nm. |

Note | Do not renew securing bolts. |

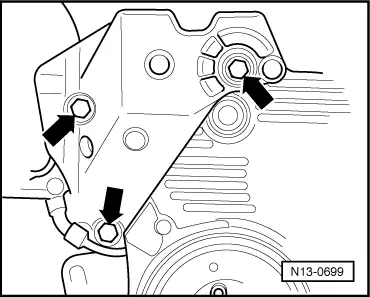

| Continuation for all versions |

| –

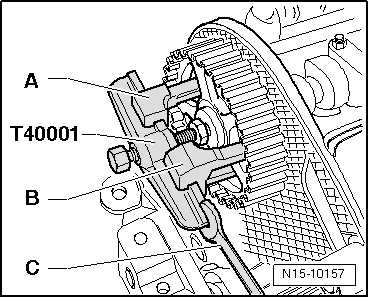

| Remove camshaft bar -T10098 A- from camshaft. |

| –

| Turn crankshaft two rotations in engine DOR and set again to TDC no. 1 cylinder. |

| –

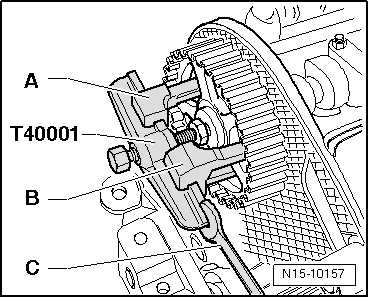

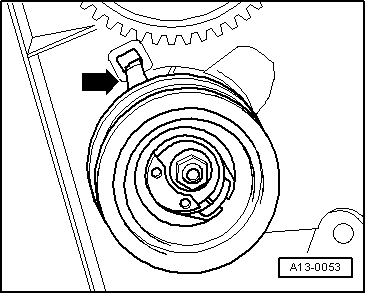

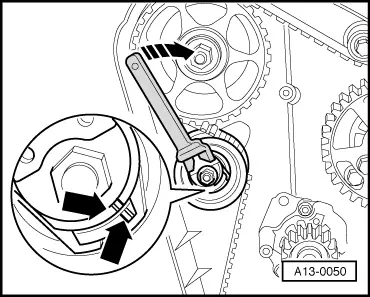

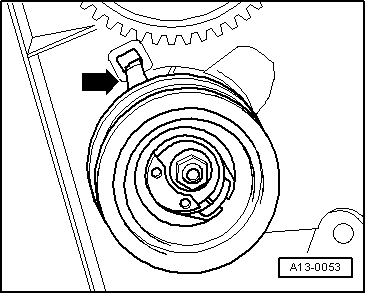

| Check TDC marking on flywheel, whether camshaft bar fits in camshaft, whether locking pin fits in injection pump belt pulley, adjustment of tensioning roller (notch/protrusion or notch/arrow). |

| –

| If notch and protrusion or notch and arrow are not aligned, adjust tension of tensioning roller and tighten securing nut to 20 Nm. |

| –

| Turn crankshaft two rotations in engine D.O.R. until crankshaft is set to TDC No. 1 cylinder again. |

|

|

|

Note

Note Note

Note

Note

Note Note

Note

Note

Note

Note

Note Note

Note

Note

Note Note

Note

Note

Note