| –

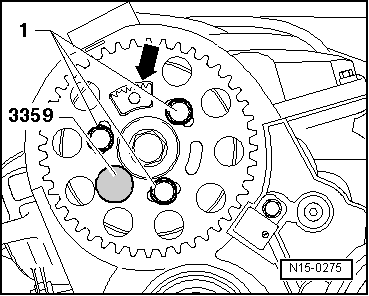

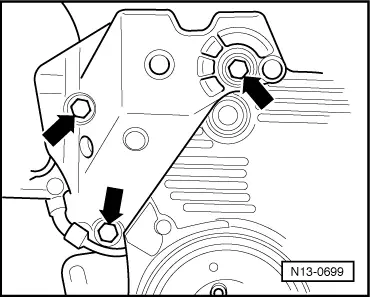

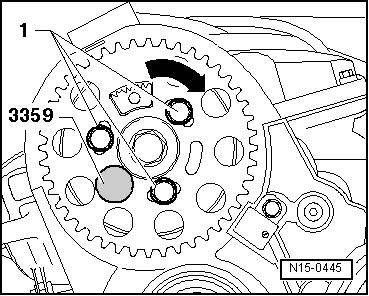

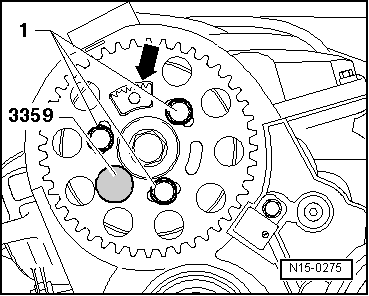

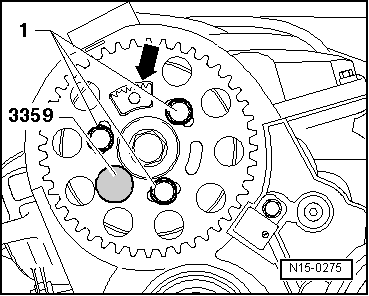

| Tighten bolts -1- of camshaft toothed belt pulley to 25 Nm. |

| –

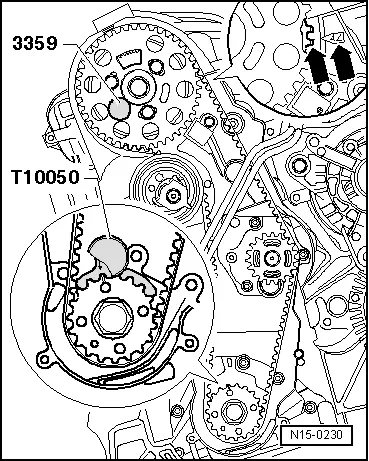

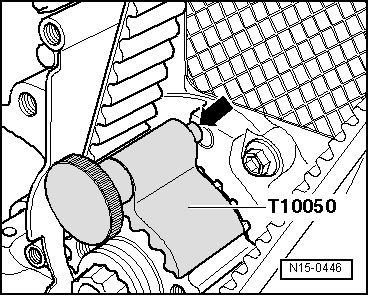

| Remove locking pin for diesel injection pump -3359- and crankshaft stop -T10050-. |

| –

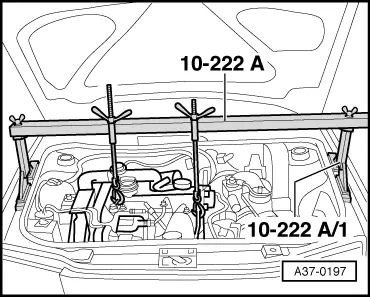

| Turn crankshaft two rotations in engine direction of rotation and set again to TDC no. 1 cylinder. |

Note | t

| When doing this, the crankshaft stop pin must engage in the sealing flange whilst turning. |

| t

| If the crankshaft is turned past TDC no. 1 cylinder and the crankshaft stop could not engage in the sealing flange, turn the crankshaft back 1/4 turn so that the crankshaft can again be turned in engine direction of rotation to allow it to be set to TDC no. 1 cylinder. Making corrections against engine direction of rotation in order to insert the crankshaft stop is not permissible. |

| –

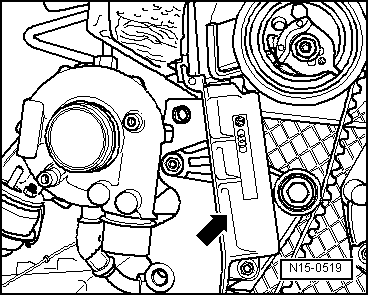

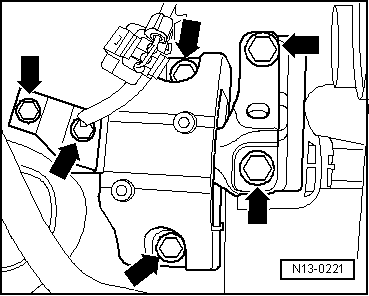

| Once crankshaft stop -T10050- has been inserted, check whether: |

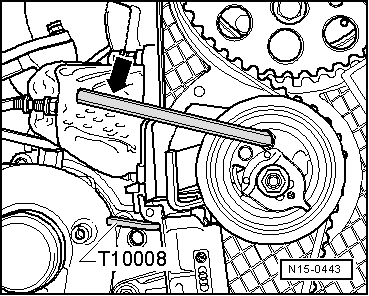

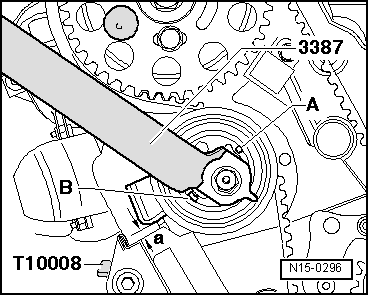

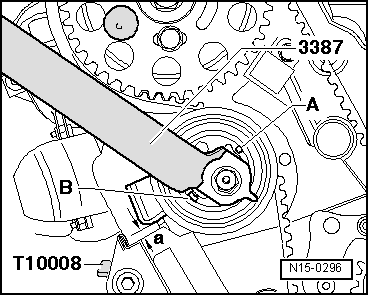

| 1.) Dimension -a- can be reached. |

| 2.) The hub can be locked using locking pin for diesel injection pump -3359-. |

| If dimension -a- is not achieved: |

| –

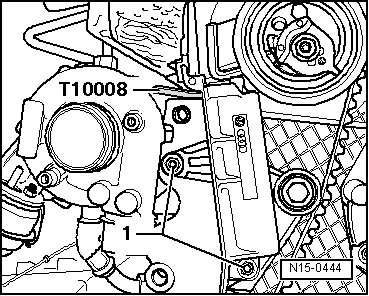

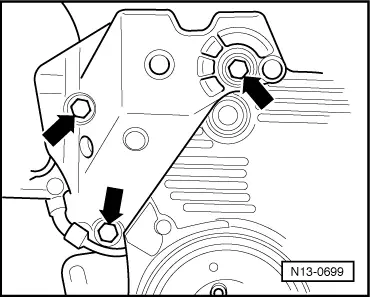

| Tension the tensioning roller again. To do this, counterhold tensioning roller using pin wrench -3387-, loosen securing nut and adjust counterforce of tensioning device until measurement -a- is achieved. Specification -a-: 4 ± 1 mm. |

| –

| Tighten securing nut to 20 Nm and 45° (1/8 turn) further. |

| If the hub cannot be locked: |

| –

| Pull crankshaft stop pin out of drilling in sealing flange and turn crankshaft until hub can be locked with locking pin. |

|

|

|

Note

Note

Note

Note

Note

Note Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

WARNING

WARNING