Golf Mk4

| Part III |

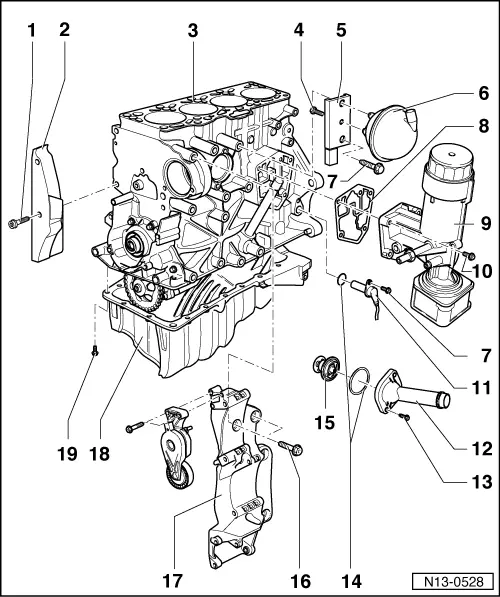

| 1 - | 45 Nm |

| 2 - | Screen |

| 3 - | Cylinder block |

| q | Removing and installing sealing flange and flywheel → Chapter |

| q | Removing and installing crankshaft → Chapter. |

| q | Dismantling and assembling pistons and conrods → Chapter |

| 4 - | 10 Nm |

| 5 - | Bracket |

| q | For vacuum reservoir |

| 6 - | Vacuum reservoir |

| q | Attached to charge air pipe on vehicles with engine code ARL → Chapter Removing and installing parts of charge air cooling system |

| 7 - | 15 Nm |

| 8 - | Gasket |

| q | Renew |

| 9 - | Oil filter bracket |

| q | Dismantling and assembling → Chapter. |

| 10 - | 15 Nm + turn 90° further |

| q | Renew |

| q | First fit upper left and lower right bolts and then tighten all four bolts in diagonal sequence |

| 11 - | Engine speed sender -G28- |

| 12 - | Connection |

| q | For thermostat |

| 13 - | 15 Nm |

| 14 - | O-ring |

| q | Renew |

| 15 - | Thermostat |

| q | Removing and installing → Chapter |

| q | Observe installation position, → Chapter Removing and installing thermostat |

| q | Checking: Heat thermostat in water. |

| q | Opening begins at approx. 85 °C. |

| q | Ends at approx. 105 °C. |

| q | Opening lift min. 7 mm. |

| 16 - | 45 Nm |

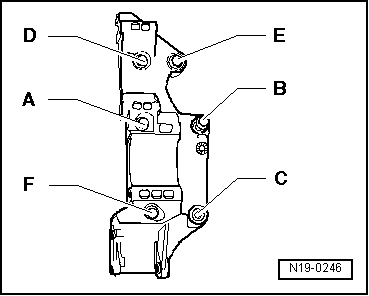

| q | Observe tightening sequence → Fig.. |

| 17 - | Bracket for ancillaries |

| q | For alternator, power steering vane pump and A/C compressor |

| 18 - | Sump |

| q | Clean sealing surface before fitting. |

| q | Install with silicone sealant -D 176 404 A2- → Chapter. |

| 19 - | 15 Nm |