| –

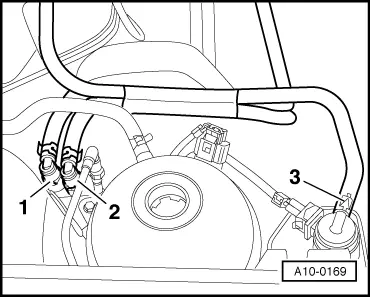

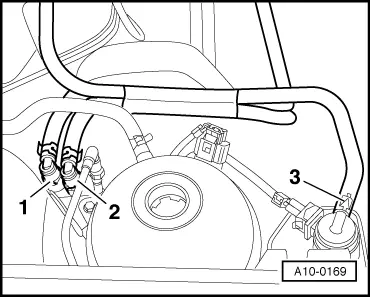

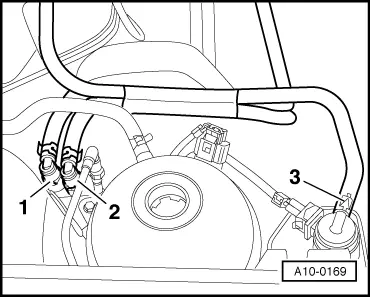

| Pull off supply hose -1- (with white marking) and return hose -2- (with blue marking) and catch fuel that escapes in a cloth. |

| –

| Pull hose off activated charcoal filter system solenoid valve 1 -N80--3-. |

WARNING | Fuel system is under pressure! Before opening the system place a cloth around the connection. Then release pressure by carefully loosening the connection. |

|

Note | Press in securing ring to release fuel lines. |

| –

| Seal lines so that fuel system is not contaminated by dirt. |

| –

| Detach connectors from the following components: |

| t

| Ignition transformer -N152- |

| t

| Injector, cylinder 1 -N30- |

| t

| Injector, cylinder 2 -N31- |

| t

| Injector, cylinder 3 -N32- |

| t

| Injector, cylinder 4 -N33- |

| t

| Coolant temperature sender -G62- |

| t

| Engine speed sender -G28- |

| t

| Exhaust gas recirculation valve -N18- with exhaust gas recirculation potentiometer -G212- |

| t

| Secondary air pump motor -V101- |

| t

| Oil pressure switch -F1- |

| t

| Throttle valve module -J338- |

| t

| If necessary, air conditioning system switch off thermal switch -F163- |

| –

| Remove air filter with intake hose and air mass meter -G70-. |

| –

| Remove upper part of intake manifold. |

Note | Seal intake ports in lower part of intake manifold using a clean cloth. |

| Vehicles with manual gearbox |

Note | Clutch pedal must not be depressed. |

| Vehicles with automatic gearbox |

| Continuation for all vehicles |

| –

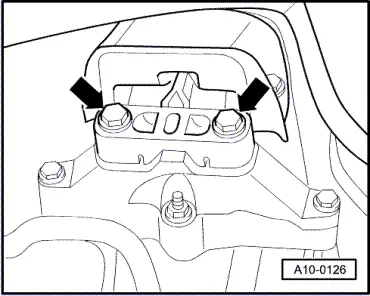

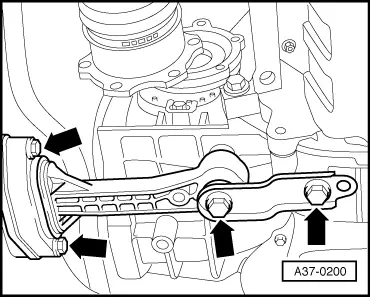

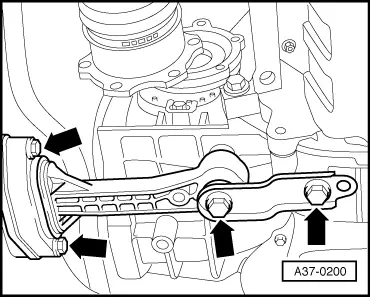

| Remove securing clamps for power-assisted steering pressure line. |

| –

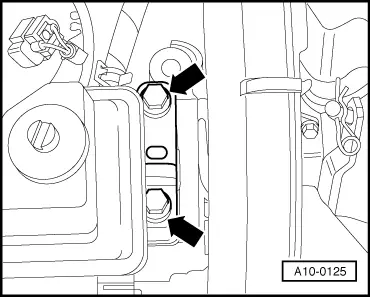

| Unbolt power assisted steering vane pump from bracket and lay to side, hoses remain connected: → Rep. gr.48. |

| Vehicles with air conditioning system: |

| –

| Remove air conditioner compressor: |

| –

| Observe additional information and installation work → Chapter. |

| –

| Remove inter-connecting, coolant, vacuum and intake hoses on engine. |

| –

| Remove secondary air pump and bracket. |

| –

| Disconnect all electrical wiring from gearbox, alternator and starter and lay to side. |

| –

| Pull off or disconnect all other electrical connections as necessary from engine and lay to side. |

|

|

|

Note

Note Note

Note Note

Note Note

Note

Note

Note

Note

Note

Note

Note Note

Note Note

Note Note

Note

Note

Note

Note

Note