Golf Mk4

| Removing and installing oil seal on Hall sender |

| Special tools and workshop equipment required |

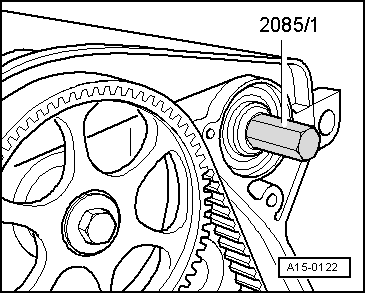

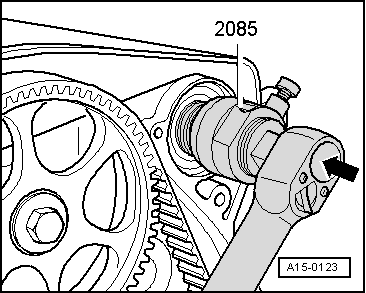

| t | Oil seal extractor -2085- |

| t | Counterhold tool -3036- |

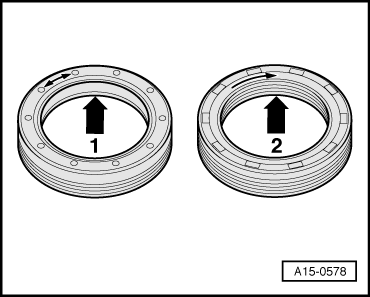

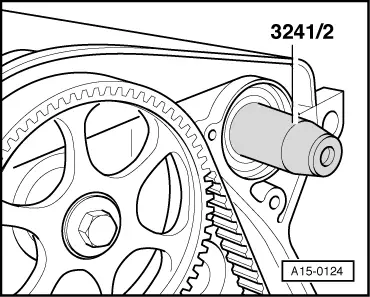

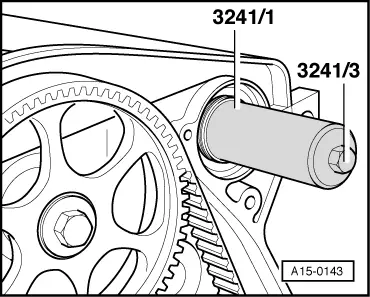

| t | Fitting sleeves -3241- |

| t | Torque wrench -V.A.G 1331- (5...50 Nm) |

| t | Torque wrench -V.A.G 1332- (40...200 Nm) |

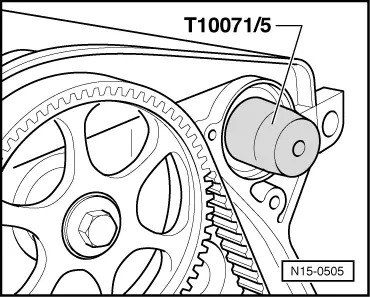

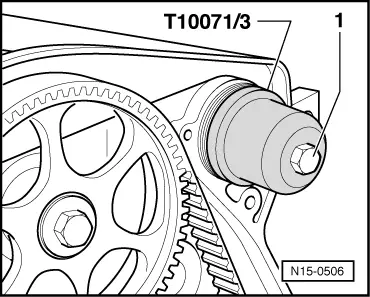

| t | Fitting tool -T10071- |

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|