| –

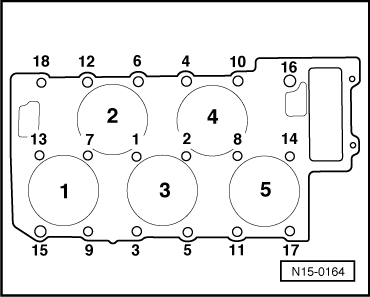

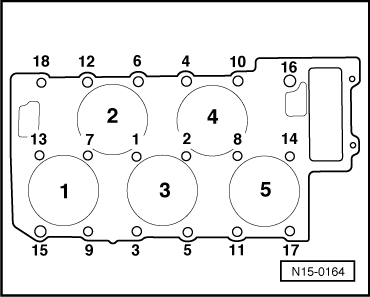

| Place clean cloths in cylinders so that no dirt or emery cloth particles can get in between cylinder wall and piston. |

| –

| Also prevent dirt and emery cloth particles from getting into coolant. |

| –

| Now carefully clean sealing surfaces of cylinder head and cylinder block. Ensure thereby that surfaces are not scored or scratched (if abrasive paper is used, grade must not be less than 100). |

| –

| Carefully remove metal particles, emery residue and cloths. |

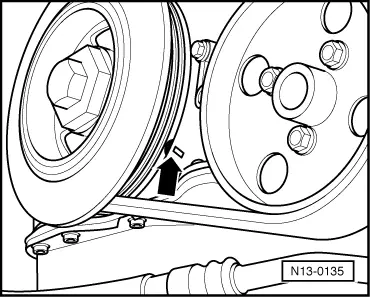

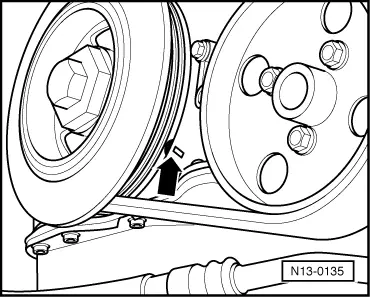

| If piston of no. 1 cylinder is not at TDC: |

|

|

|

Note

Note

Note

Note Note

Note

Note

Note

Note

Note Note

Note