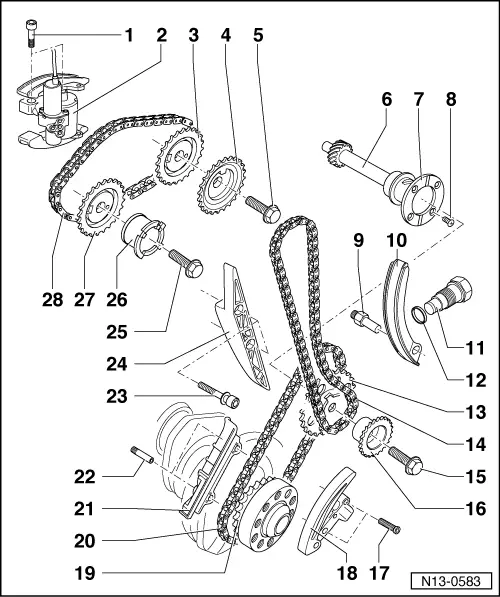

Golf Mk4

| Part I: chain drive - engine codes AQP and AUE - assembly overview |

| 1 - | 25 Nm |

| 2 - | Camshaft adjuster |

| q | Rotate engine only with camshaft adjuster installed. |

| q | With camshaft adjuster valve 1 -N205-. |

| q | Before removing, lock in position with chain tensioner retainer -T10067- → Chapter. |

| 3 - | Camshaft chain sprocket |

| q | For exhaust camshaft and drive chain → Item |

| q | Removing and installing → Chapter |

| 4 - | Chain sprocket |

| q | For camshaft timing chain → Item |

| q | Contact surface of chain sprocket must be dry around bolt head when assembled. |

| q | Installing → Chapter. |

| 5 - | 60 Nm + 1/4 turn (90°) further |

| q | Renew. |

| q | Contact surface of chain sprocket must be dry around bolt head when assembled. |

| q | To remove and install counterhold with 32 mm open-end spanner on camshaft → Chapter |

| 6 - | Intermediate shaft |

| 7 - | Thrust washer |

| 8 - | 10 Nm |

| 9 - | Pivot pin, 18 Nm |

| q | For tensioning rail → Item |

| 10 - | Tensioning plate |

| q | For camshaft timing chain → Item |

| 11 - | Chain tensioner, 40 Nm |

| q | For camshaft timing chain → Item |

| q | Only rotate engine when chain tensioner is installed. |

| 12 - | Seal |

| q | Renew if damaged or leaking. |

| 13 - | Chain sprocket |

| q | For timing chain → Item. |

| q | Installing → Chapter. |

| 14 - | Camshaft timing chain |

| q | Before removing, mark direction of rotation (installation position) → Fig.. |

| q | Installing → Chapter. |

| 15 - | 60 Nm + 1/4 turn (90°) further |

| q | Renew. |

| q | To tighten and loosen, use counterhold -T10069- → Chapter |

| 16 - | Chain sprocket |

| q | For camshaft timing chain → Item |

| q | Installing → Chapter. |

| 17 - | 8 Nm |

| 18 - | Chain tensioner with tensioning plate |

| q | For timing chain → Item. |

| q | Before installing, release locking splines in chain tensioner using a small screwdriver and press tensioning plate against chain tensioner. |

| q | Only rotate engine when chain tensioner is installed. |

| 19 - | Drive sprocket |

| q | Built into crankshaft. |

| q | Ground down tooth aligned with main bearing joint = TDC No. 1 cylinder → Chapter |

| 20 - | Timing chain |

| q | Before removing, mark direction of rotation (installation position) → Fig.. |

| q | Installing → Chapter. |

| 21 - | Guide rail |

| q | For timing chain → Item. |

| q | Removing and installing together with timing chain → Chapter |

| 22 - | Locating pin without collar, 10 Nm |

| q | For guide rail → Item. |

| 23 - | 23 Nm |

| q | For guide rail → Item. |

| 24 - | Guide rail |

| q | For camshaft timing chain → Item |

| 25 - | 60 Nm + 1/4 turn (90°) further |

| q | Renew. |

| q | Contact surface of sender wheel must be dry around bolt head when assembled. |

| q | To remove and install counterhold with 32 mm open-end spanner on camshaft → Chapter |

| 26 - | Sender wheel |

| q | Contact surface of camshaft timing chain sprocket and sender wheel must be dry when assembled. |

| q | For Hall sender -G40-. |

| q | Removing and installing → Chapter |

| 27 - | Camshaft chain sprocket |

| q | For inlet camshaft and drive chain → Item |

| q | Removing and installing → Chapter |

| 28 - | Drive chain |

| q | Before removing, mark direction of rotation (installation position) → Chapter. |